| “This site contains affiliate links for which OEMDTC may be compensated” |

May 14, 2014 NHTSA CAMPAIGN NUMBER: 14V252000

Brake Lights may or may not Randomly Illuminate

Any of the above failure conditions increases the risk of a crash.

NHTSA Campaign Number: 14V252

Manufacturer General Motors LLC

LLC

Components SERVICE BRAKES, HYDRAULIC, ELECTRICAL SYSTEM, EXTERIOR LIGHTING, VEHICLE SPEED CONTROL, ELECTRONIC STABILITY CONTROL

Potential Number of Units Affected 2,440,524

Summary

General Motors LLC (GM) is recalling certain model year 2004-2012 Chevrolet Malibu vehicles manufactured May 16, 2003, through October 11, 2012, 2004-2007 Malibu Maxx vehicles manufactured June 25, 2003, through April 5, 2007, 2005-2010 Pontiac

LLC (GM) is recalling certain model year 2004-2012 Chevrolet Malibu vehicles manufactured May 16, 2003, through October 11, 2012, 2004-2007 Malibu Maxx vehicles manufactured June 25, 2003, through April 5, 2007, 2005-2010 Pontiac G6 vehicles manufactured May 26, 2004, through January 4, 2010, and 2007-2010 Saturn

G6 vehicles manufactured May 26, 2004, through January 4, 2010, and 2007-2010 Saturn Aura vehicles manufactured April 24, 2006, through May 26, 2009. In the affected vehicles, increased resistance in the Body Control Module (BCM) connection may result in voltage fluctuations in the Brake Apply Sensor (BAS) circuit. These fluctuations can cause one or more of these conditions: the brake lights to illuminate without the brake pedal being pushed; the brake lights to not illuminate when the pedal is pushed; difficulty disengaging the cruise control; moving the gear shifter out of the ‘PARK’ position without pushing the brake; and disablement of crash avoidance features such as traction control, electronic stability control, and panic braking assist features.

Aura vehicles manufactured April 24, 2006, through May 26, 2009. In the affected vehicles, increased resistance in the Body Control Module (BCM) connection may result in voltage fluctuations in the Brake Apply Sensor (BAS) circuit. These fluctuations can cause one or more of these conditions: the brake lights to illuminate without the brake pedal being pushed; the brake lights to not illuminate when the pedal is pushed; difficulty disengaging the cruise control; moving the gear shifter out of the ‘PARK’ position without pushing the brake; and disablement of crash avoidance features such as traction control, electronic stability control, and panic braking assist features.

Remedy

GM will notify owners, and dealers will attach the wiring harness to the BCM with a spacer, apply dielectric lubricant to both the BCM and harness connector and the BAS and harness connector, and will relearn the brake pedal home position, free of charge. The manufacturer distributed an Interim letter to customers on July 14, 2014. The recall began on August 18, 2014. Owners may contact General Motors customer service at 1-800-222-1020 (Chevrolet), 1-800-762-2737 (Pontiac

customer service at 1-800-222-1020 (Chevrolet), 1-800-762-2737 (Pontiac ), 1-800-553-6000 (Saturn

), 1-800-553-6000 (Saturn ). GM’s number for this recall is 13036.

). GM’s number for this recall is 13036.

Notes

Owners may also contact the National Highway Traffic Safety Administration Vehicle Safety Hotline at 1-888-327-4236 (TTY 1-800-424-9153), or go to www.safercar.gov.

Check if your Vehicle has a Recall

Parts

| Retainer-Brk Ped (Short Tie Strap – Pkg of 10) | 1 | 15188763 |

| Strap-EGR Tube (Long Tie Strap – Pkg of 10) | 2 | 11509086 |

| 14 Inch Tie Strap | 1 | Obtain Locally |

| Clip-Wrg Harn (Tie-Down Mount) | 1 | 13596990 |

| Retainer-Acsry Wrg Harn (Rubber Spacer) | 1 (If Required) | 13596991 |

| Promoter, Plastic Adhesion (4 OZ) – US | As Required

| 12378462 |

| Promoter, Plastic Adhesion (4 OZ) – CA | 10953554 | |

| Lubricant, Dielectric (2 OZ) – US | As Required | 12377900 |

| Lubricant, Dielectric (2 OZ) – CA | 10953529 | |

| KENT AUTOMOTIVE

Woven Polyester Electrical Tape (PET) | As Required | 1089482 |

Parts

SEOCONTENT-START

#13036D: Product Safety Recall – Brake Lamp Malfunction – (May 18, 2017)

| Subject: | 13036D – Brake Lamp Malfunction |

| Models: | 2004-2012 Chevrolet Malibu |

| 2004-2007 Chevrolet Malibu Maxx | |

2005-2010 Pontiac G6 G6 |

|

2007-2010 Saturn AURA AURA |

The bulletin has been revised to update the Warranty Transaction Information section to include the 14 inch tie strap in Net Item allowance. Please discard all copies of bulletin 13036C.

It is a violation of Federal law for a dealer to deliver a new motor vehicle or any new or used item of motor vehicle equipment (including a tire) covered by this notification under a sale or lease until the defect or noncompliance is remedied.

All involved vehicles that are in dealer inventory must be held and not delivered to customers, dealer traded, or used for demonstration purposes until the repair contained in this bulletin has been performed on the vehicle.

Condition

General Motors has decided that a defect which relates to motor vehicle safety exists in 2004-2012 model year (MY) Chevrolet Malibu, 2004-2007 MY Chevrolet Malibu Maxx, 2005-2010 MY Pontiac

has decided that a defect which relates to motor vehicle safety exists in 2004-2012 model year (MY) Chevrolet Malibu, 2004-2007 MY Chevrolet Malibu Maxx, 2005-2010 MY Pontiac G6, 2007-2010 MY Saturn

G6, 2007-2010 MY Saturn AURA vehicles. On these vehicles, over time an increased resistance can develop in the Body Control Module (BCM) connection system and result in voltage fluctuations or intermittency in the Brake Apply Sensor (BAS) circuit that can cause service brake lamp malfunction. As a result, the service brake lamps may illuminate when the service brakes are not being applied, or may not illuminate when the service brakes are being applied. Additionally, cruise control may not engage. If cruise control is engaged, additional service brake pedal travel may be required to disengage it. Service brake pedal application may not be required to move the shift lever out of PARK, or additional service brake pedal travel may be required to move the shift lever out of PARK. Traction control, electronic stability control, and panic braking assist features, if equipped, may be disabled. Service ESC and/or Traction Control tell-tales may illuminate with this condition. These conditions may increase the risk of a crash.

AURA vehicles. On these vehicles, over time an increased resistance can develop in the Body Control Module (BCM) connection system and result in voltage fluctuations or intermittency in the Brake Apply Sensor (BAS) circuit that can cause service brake lamp malfunction. As a result, the service brake lamps may illuminate when the service brakes are not being applied, or may not illuminate when the service brakes are being applied. Additionally, cruise control may not engage. If cruise control is engaged, additional service brake pedal travel may be required to disengage it. Service brake pedal application may not be required to move the shift lever out of PARK, or additional service brake pedal travel may be required to move the shift lever out of PARK. Traction control, electronic stability control, and panic braking assist features, if equipped, may be disabled. Service ESC and/or Traction Control tell-tales may illuminate with this condition. These conditions may increase the risk of a crash.

Correction

Dealers are to attach the wiring harness to the BCM with a spacer, apply dielectric lubricant to the BCM X2 (C2) connector and the BAS harness connector, and relearn the brake pedal home position. Please see the checklist for all of the required steps for proper repair.

Vehicles Involved

All involved vehicles are identified by Vehicle Identification Number on the Investigate Vehicle History screen in GM Global Warranty Management system. Dealership service personnel should always check this site to confirm vehicle involvement prior to beginning any required inspections and/or repairs. It is important to routinely use this tool to verify eligibility because not all similar vehicles may be involved regardless of description or option content.

For dealers with involved vehicles, a listing with involved vehicles containing the complete vehicle identification number, customer name, and address information has been prepared and will be provided to U.S. and Canadian dealers through the GM GlobalConnect Recall Reports, or sent directly to export dealers. Dealers will not have a report available if they have no involved vehicles currently assigned.

The listing may contain customer names and addresses obtained from Motor Vehicle Registration Records. The use of such motor vehicle registration data for any purpose other than follow-up necessary to complete this recall is a violation of law in several states/provinces/countries. Accordingly, you are urged to limit the use of this report to the follow-up necessary to complete this recall.

Parts Information

Parts required to complete this recall are to be obtained from General Motors Customer Care and Aftersales (GMCCA). Please refer to your “involved vehicles listing” before ordering parts. This part will be on Order Writing control initially and all DRO’s (Daily Replenishment Orders) will cancel. Dealers can place orders CSO (Customer Special Order). In emergency situations a dealer should place a SPAC case and the orders will be processed in the order received.

Customer Care and Aftersales (GMCCA). Please refer to your “involved vehicles listing” before ordering parts. This part will be on Order Writing control initially and all DRO’s (Daily Replenishment Orders) will cancel. Dealers can place orders CSO (Customer Special Order). In emergency situations a dealer should place a SPAC case and the orders will be processed in the order received.

| Part Number | Description | Quantity/Vehicle |

| 15188763 |

Retainer-Brk Ped (Short Tie Strap – Pkg of 10) | 1 |

| 11509086 |

Strap-EGR Tube (Long Tie Strap – Pkg of 10) | 2 |

| Obtain Locally | 14 Inch Tie Strap | 1 (Submit as Net Item) |

| 13596990 |

Clip-Wrg Harn (Tie-Down Mount) | 1 |

| 13596991 |

Retainer-Acsry Wrg Harn (Rubber Spacer) | 1 (If Required) |

| 12378462 |

Promoter, Plastic Adhesion (4 OZ) – US | As Required

(Submit as Net Item) |

| 10953554 | Promoter, Plastic Adhesion (4 OZ) – CA | |

| 12377900 |

Lubricant, Dielectric (2 OZ) – US | As Required

(Submit as Net Item) |

| 10953529 | Lubricant, Dielectric (2 OZ) – CA | |

| 1089482 | KENT AUTOMOTIVE

Woven Polyester Electrical Tape (PET) (Do not order from GMCCA – Obtain Locally) |

As Required

(Submit as Net Item) |

Parts required to complete this recall are to be obtained from General Motors Customer Care and Aftersales (GMCC&A). Please refer to your “involved vehicles listing” before ordering parts. Normal orders should be placed on a DRO = Daily Replenishment Order. In an emergency situation, parts should be ordered on a CSO = Customer Special Order.

Customer Care and Aftersales (GMCC&A). Please refer to your “involved vehicles listing” before ordering parts. Normal orders should be placed on a DRO = Daily Replenishment Order. In an emergency situation, parts should be ordered on a CSO = Customer Special Order.

* Contact Kent Automotive at 1-888-937-5368, or www.kent-automotive.com. Dealers that do not have a Kent Automotive account or representative must advise the Customer Service Representative that the part(s) is being used for this GM bulletin to obtain special bulletin pricing. Do not order from GMCCA.

Reminder: Parts may be removed from Retail Inventory Management (RIM) management. Dealers should review the affected parts to confirm RIM managed status. Parts may have quantity limiters in effect.

Service Procedure

Service Procedure Checklist

The following checklist is ONLY intended to supplement recall bulletin 13036. It is NOT designed to replace the service information. This checklist assumes that you have read, understand, and will closely follow all of the steps in the recall bulletin to ensure a proper repair. Please use this as a guide while performing the recall bulletin to ensure ALL of the required repairs are performed.

- Perform a terminal drag test on the brake pedal position sensor (BPPS) cavity terminals.

- Apply dielectric lubricant to brake pedal position sensor (BPPS) cavity terminals.

- Apply dielectric lubricant to BPPS connector.

- Cut off existing gray tie strap to obtain more wiring harness slack for BCM connection.

- Remove tie strap from BCM connector X2 (C2) harness.

- Install NEW tie straps to BCM connector X2 (C2) harness.

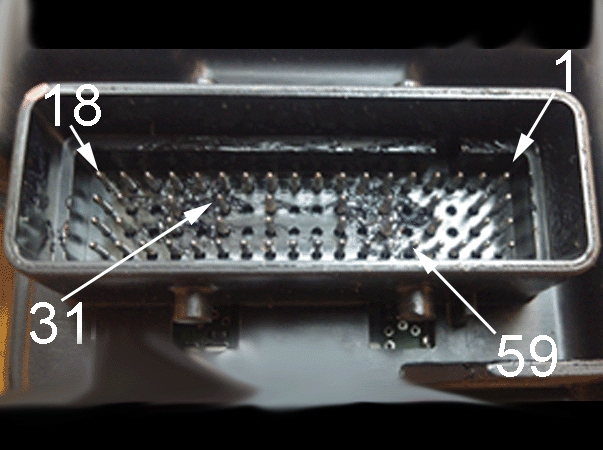

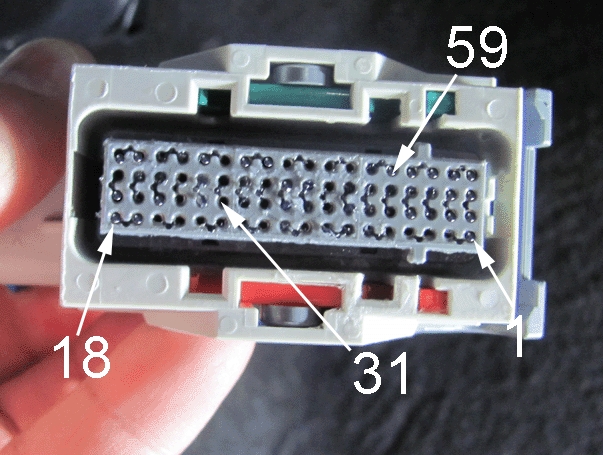

- Perform a terminal drag test on BCM connector X2 (C2) terminals 18, 31, and 59.

- Apply dielectric lubricant to BCM terminals in cavity X2 (C2).

- Apply dielectric lubricant to connector face of BCM connector X2 (C2).

- Apply adhesion promoter, install tie-down mount, tie strap and rubber spacer to upper corner of BCM (Pontiac

G6, Saturn

G6, Saturn AURA, and 2008-2012 Chevrolet Malibu)

AURA, and 2008-2012 Chevrolet Malibu) - Clean the surface of the IP Mag Beam using an alcohol wipe, apply adhesion promoter, install tie-down mount and tie straps to IP Mag Beam (rubber spacer is not needed for the following models) (2004-2007 Chevrolet Malibu Sedan and Maxx, and 2008 Chevrolet Malibu Classic)

- Perform the brake pedal position sensor calibration.

Dielectric Lubricant Application Procedure (All Models)

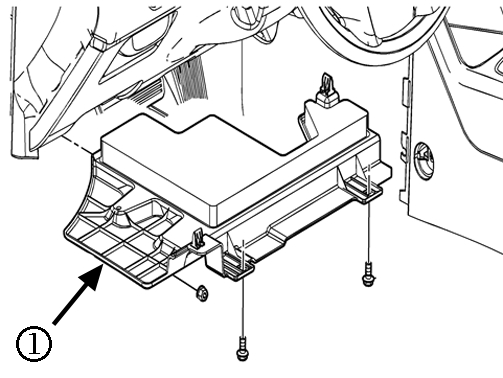

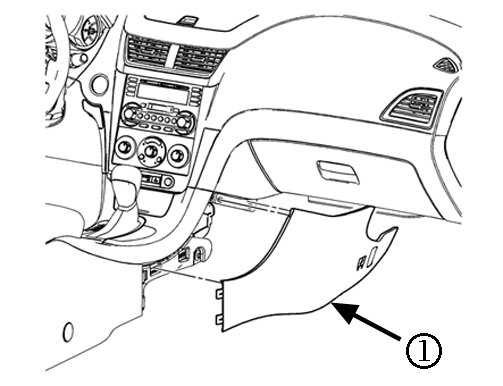

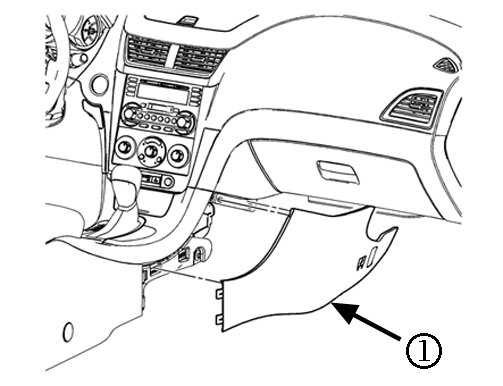

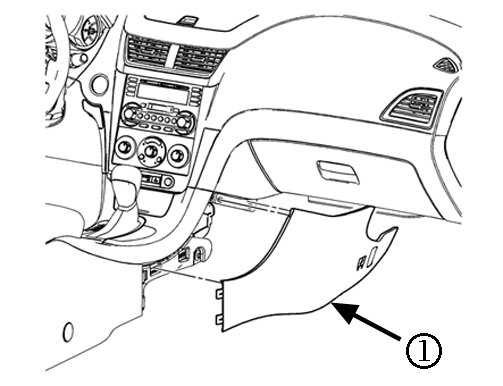

- Remove the driver side instrument panel insulator panel (1). Refer to Instrument Panel Insulator Replacement – Left Side in SI.

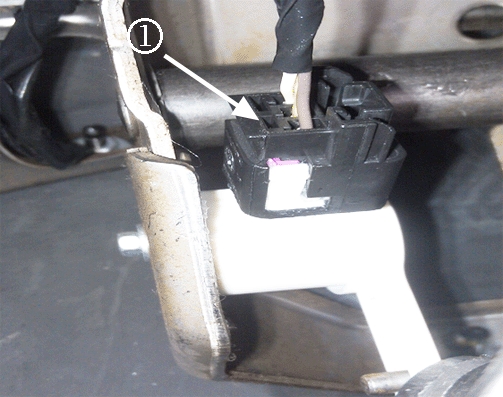

- Disconnect the Brake Pedal Position Sensor (BPPS) connector (1).

Caution: ONLY use test leads from J-35616-F, GM Terminal Test Probe Kit, to front probe terminals. Do not insert test equipment probes (DMM etc.) into any connector or fuse block terminal. Do not use paper clips or other substitutes to probe terminals. The diameter of an incorrect test probe will deform most female terminals. A deformed terminal will result in a poor connection and system failure.

When using the J-35616-F GM Terminal Test Probe Kit, ensure the terminal diagnostic test probe is the correct size for the connector terminal. Do not visually choose the terminal diagnostic test probe because some connector terminal cavities may appear larger than the actual terminal in the cavity. Refer to the connector end view in SI or the label inside of the J-35616-F GM Terminal Test Probe Kit cover to ensure the correct terminal diagnostic test probe is selected.

- Using terminal adapter J-35616-2A (GY), perform a terminal drag test on the BPPS connector terminals. Verify that the retention force is significantly different between a known good terminal and the suspect terminal. Replace any female terminal(s) in question.

- Using the applicator stick, apply a smaller 5 mm x 5 mm x 5 mm dab of dielectric lubricant completely across all of the terminal pins in the BPPS connector cavity.

- Use a one-inch nylon bristle brush to spread the lubricant evenly onto all terminal pins.

- Apply a 5 mm x 5 mm x 5 mm dab of dielectric lubricant completely across the connector face of the BPPS connector.

- Use a one-inch nylon bristle brush to spread the lubricant evenly into all terminal holes.

- Reconnect the connector back on the BPPS.

- Reinstall the driver side instrument panel insulator panel (1). Refer to Instrument Panel Insulator Replacement – Left Side in SI.

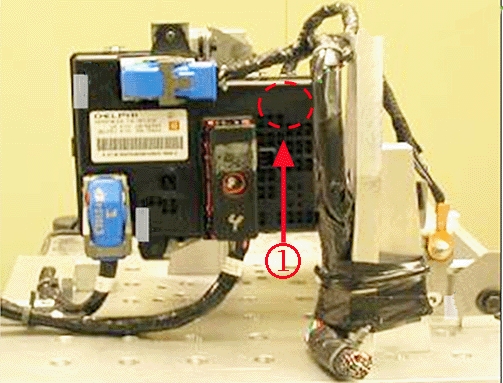

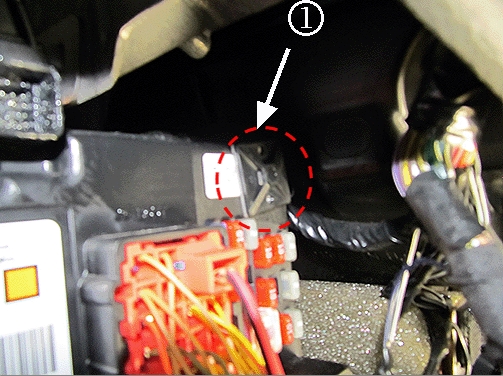

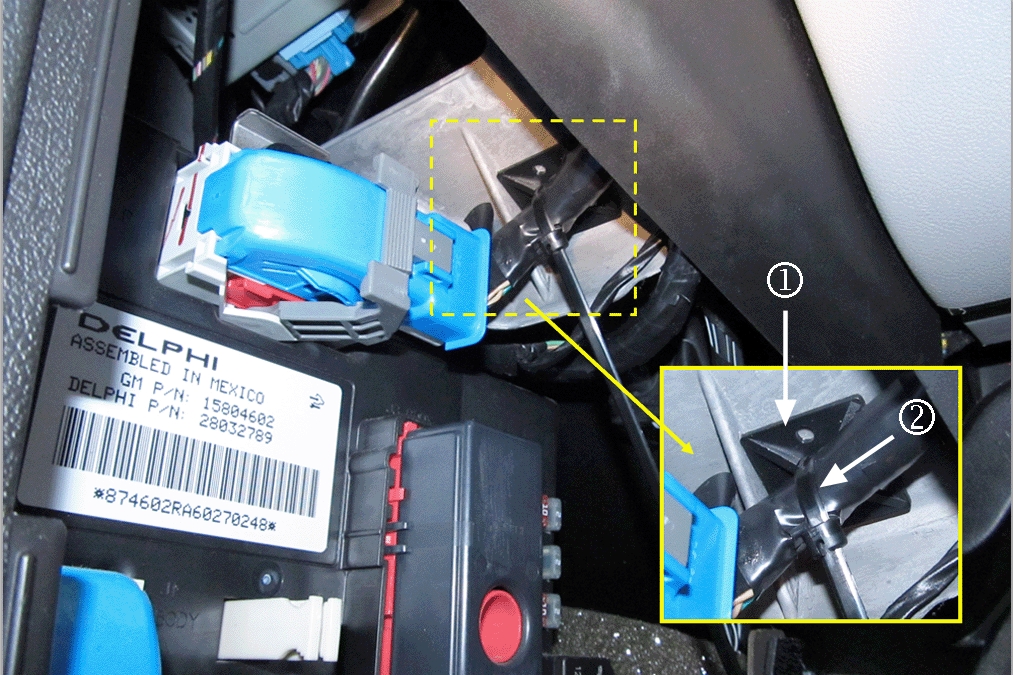

- Remove the right side front floor console side trim panel (1) to access the Body Control Module (BCM).

Caution: ONLY use test leads from J-35616-F, GM Terminal Test Probe Kit, to front probe terminals. Do not insert test equipment probes (DMM etc.) into any connector or fuse block terminal. Do not use paper clips or other substitutes to probe terminals. The diameter of an incorrect test probe will deform most female terminals. A deformed terminal will result in a poor connection and system failure.

When using the J-35616-F GM Terminal Test Probe Kit, ensure the terminal diagnostic test probe is the correct size for the connector terminal. Do not visually choose the terminal diagnostic test probe because some connector terminal cavities may appear larger than the actual terminal in the cavity. Refer to the connector end view in SI or the label inside of the J-35616-F GM Terminal Test Probe Kit cover to ensure the correct terminal diagnostic test probe is selected.

- Using terminal adapter J-35616-64B (L-BU), perform a terminal drag test on BCM X2 (C2) connector terminals 18, 31, and 59. Verify that the retention force is significantly different between a known good terminal and the suspect terminal. Replace any female terminal(s) in question.

- Remove the blue latch cover from the connector.

Caution: Be careful not to damage the harness when cutting the tie strap push pin.

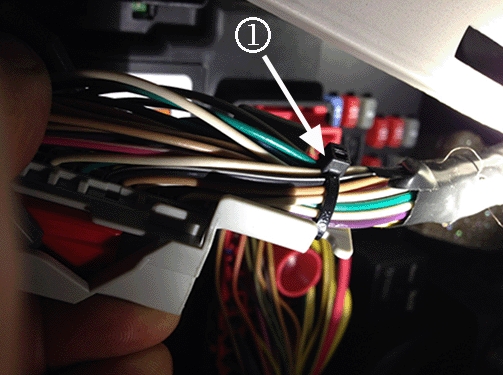

- Remove the tie strap push pin (1) from the instrument panel and cut it off of the BCM harness using side cutters. This will allow more wiring harness slack.

- To allow for installation of the tie strap added in the next step, remove the existing tie strap (1) from the end of the connector.

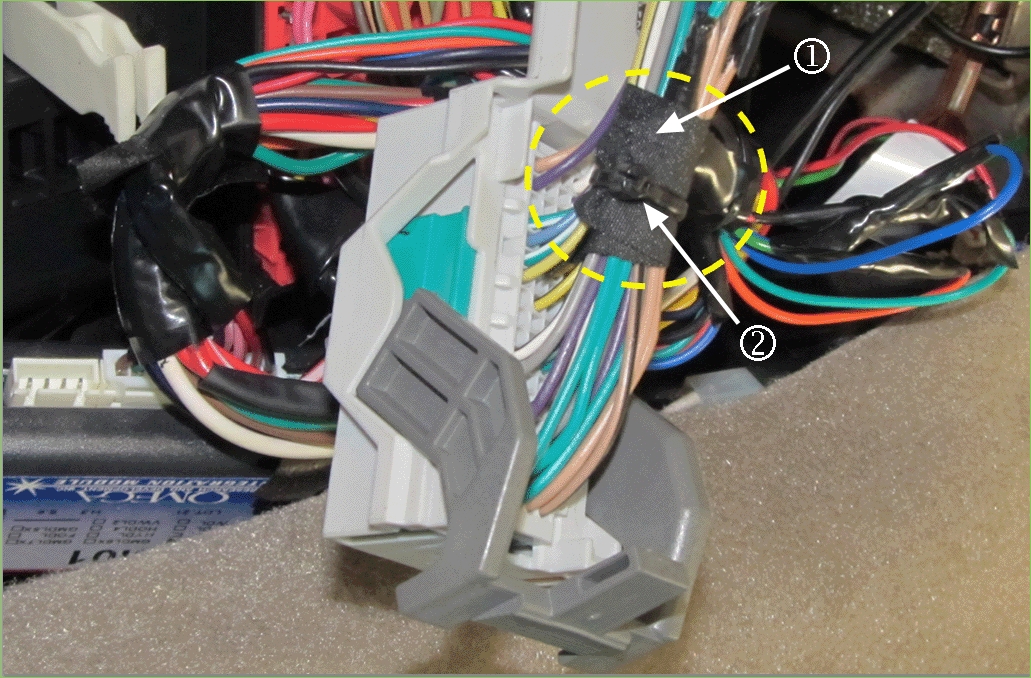

Important: ONLY use non-abrasion Woven Polyester Electrical Tape (PET). Do NOT use vinyl electrical tape.

Note: You will not be able to tie strap the complete bundle of wiring; exclude approximately the first three rows of the wiring bundle.

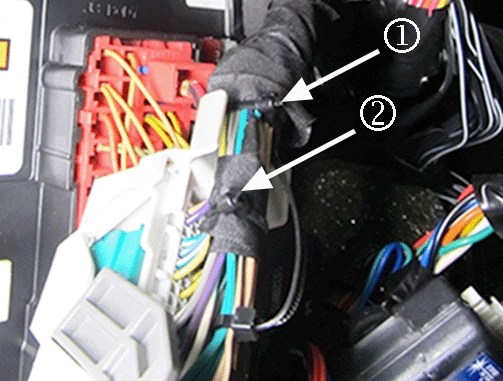

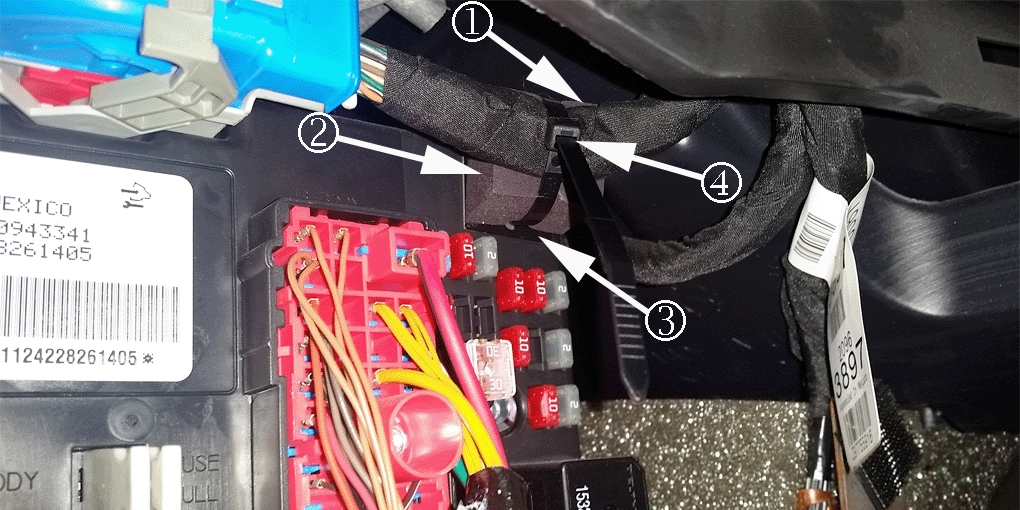

- Install Kent Automotive non-abrasion Woven Polyester Electrical Tape (PET) (1) and a new (short) tie strap (2) to the wiring within the BCM connector bundle.

- Once the additional short tie strap (2) is added, apply PET and install a new long tie strap (1) at the location where original tie strap was removed.

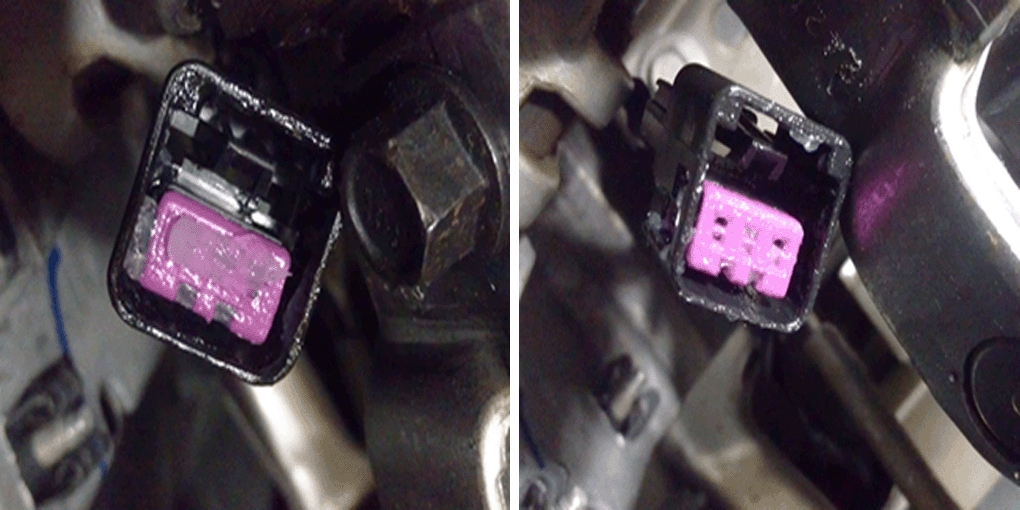

- Using the applicator stick, apply a 10 mm x 10 mm x 10 mm dab of dielectric lubricant completely across all of the terminal pins in the BCM connector cavity.

Note: Terminal 1 is called out for reference ONLY.

- Apply a 10 mm dab of dielectric lubricant (clear gel) completely across all of the terminal pins for connector X2 (C2) in the BCM. Verify that terminal pins 18, 31, & 59 are thoroughly coated.

Note: Do NOT apply dielectric lubricant outside of the cavity for connector X2 (C2) in the BCM.

- Use a one-inch nylon bristle brush to spread the lubricant evenly onto all terminal pins.

- Again using the applicator stick, apply a 10 mm dab of dielectric lubricant completely across the X2 (C2) connector face of the BCM connector.

- Use a one-inch nylon bristle brush to spread the lubricant evenly into all terminal holes. Verify that terminal locations 18, 31, & 59 are thoroughly coated.

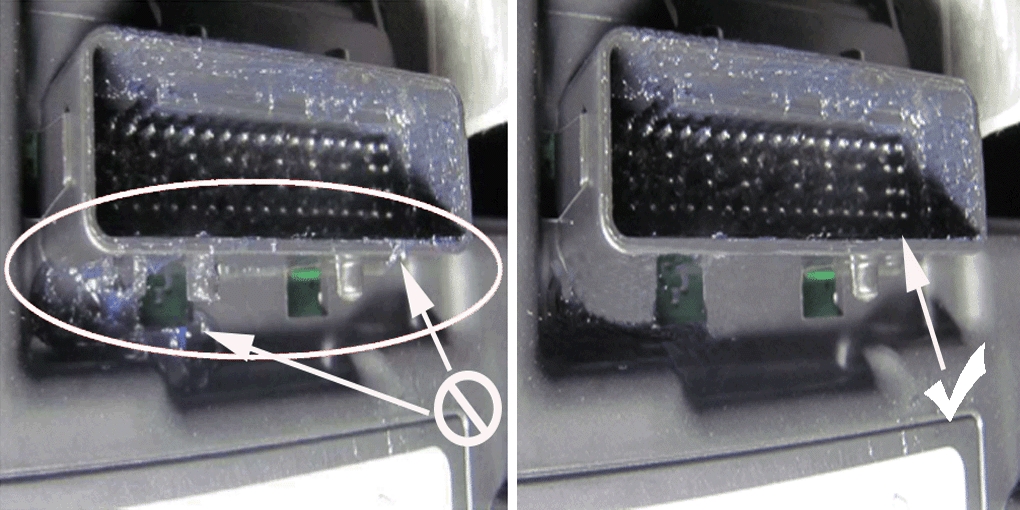

- Reinstall the blue latch cover to connector X2 (C2), reconnect the connector back on the BCM and re-latch.

- Wipe away any excess lubricant.

- Apply pressure to connector X2 (C2) to verify it is fully seated.

- Depending on vehicle model, follow the appropriate BCM Harness Tie Strap Installation Procedure below.

BCM Harness Tie Strap Installation Procedure

(Pontiac G6, Saturn

G6, Saturn AURA, and 2008-2012 Chevrolet Malibu)

AURA, and 2008-2012 Chevrolet Malibu)

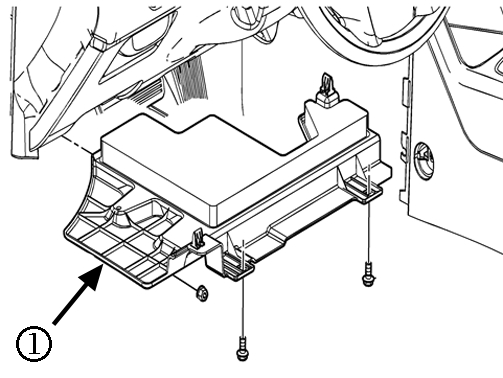

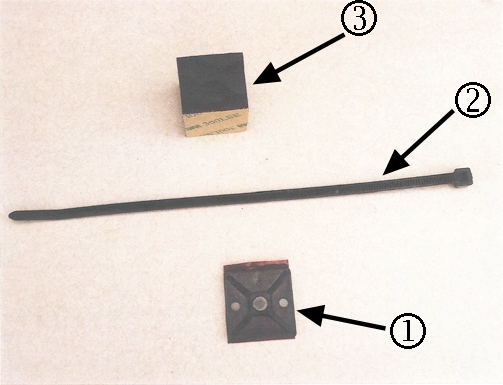

Note: The new tie-down mount (1), tie strap (2) and rubber spacer (3) will be added to secure the harness at the upper forward corner of the BCM.

- Install the new tie down clip to the outboard, upper forward corner (1) of the BCM housing.

1.1 Carefully apply GM Plastic Adhesion Promoter the upper forward corner of the BCM.

Note: Ensure the orientation of the clip is such that the slot is in the vertical direction to accept the tie strap.

1.2 Peel the backing from the adhesive on the tie down mount (1) and install the mount to the BCM. Let the promoter and adhesive set up while applying the dielectric lubricant and tape.

- Apply Kent Automotive non-abrasion PET to the BCM harness, covering the tie strap just outside the X2 (C2) connector, and extending to 25 mm (1 in) past the forward corner of the BCM as shown.

Note: Be sure to carefully cinch the tie strap completely so the harness is secured.

- Stack the new rubber spacer (2) on top of the tie-down mount (3) (installed previously), position the BCM harness across the spacer, install the long tie strap (4) through the slot on the mount and carefully cinch the tie strap.

- Reinstall the right side front floor console side trim panel (1).

- Perform the brake pedal position sensor calibration. Refer to Brake Pedal Position Sensor Calibration in SI.

- Verify proper operation of the brake lights.

BCM Harness Tie Strap Installation Procedure

(2004-2007 Chevrolet Malibu Sedan and Maxx, and 2008 Chevrolet Malibu Classic)

- Clean the surface of the IP Mag Beam using an alcohol wipe.

- Carefully apply GM Plastic Adhesion Promoter to the IP Mag Beam.

Note: DO NOT install the rubber spacer on the mount.

- Peel the backing from the adhesive on the tie-down mount and install the mount (1) to the flat underside surface of IP Mag Beam, in the location shown in the graphic above.

Note: Be sure to carefully cinch the tie strap completely so the harness is secured.

- Position the harness to the mount, install the long tie strap (2) through the slot on the mount, and carefully cinch the tie strap.

- Reinstall the right side front floor console side trim panel (1).

- Perform the brake pedal position sensor calibration. Refer to Brake Pedal Position Sensor Calibration in SI.

- Verify proper operation of the brake lights.

Customer Reimbursement – For U.S.

Customer requests for reimbursement of previously paid repairs for the recall condition are to be submitted to the dealer by August 31, 2015, unless otherwise specified by state law. If this is not convenient for the customer, they may mail the completed Customer Reimbursement Request Form and all required documents to the GM Customer Assistance Center.

All reasonable and customary costs to correct the condition described in this bulletin should be considered for reimbursement. Any questions or concerns should be reviewed with your GM representative prior to processing the request.

When a customer requests reimbursement, they must provide the following:

- A completed Customer Reimbursement Request Form. This form is mailed to the customer or can be obtained through GM GlobalConnect.

- The name and address of the person who paid for the repair.

- Paid receipt confirming the amount of the repair expense, a description of the repair, and the person or entity performing the repair.

Important: GM requires dealers to approve or deny a reimbursement request within 30 days of receipt. If a reimbursement request is approved, the dealer should immediately issue a check to the customer and submit an appropriate warranty transaction for the incurred expense. If a reimbursement request is denied, the dealer MUST provide the customer with a clear and concise explanation, in writing, as to why the request was denied. The bottom portion of the Customer Reimbursement Request Form may be used for this purpose. If the denial was due to missing documents, the customer can resubmit the request when the missing documents are obtained, as long as it is still within the allowed reimbursement period.

Warranty transactions for customer reimbursement of previously paid repairs are to be submitted as required by GM Global Warranty Management. Additional information can also be found in Warranty Administration Bulletin 11-00-89-004.

Customer Reimbursement – For Canada and Export

Customer requests for reimbursement of previously paid repairs to correct the condition described in this bulletin are to be submitted to the dealer prior to or by August 31, 2015.

When a customer requests reimbursement, they must provide the following:

- Proof of ownership at time of repair.

- Original paid receipt confirming the amount of unreimbursed repair expense(s) (including Service Contract deductibles), a description of the repair, and the person or entity performing the repair.

All reasonable and customary costs to correct the condition described in this bulletin should be considered for reimbursement. Any questions or concerns should be reviewed with your GM representative prior to processing the request.

Courtesy Transportation – For U.S. and Canada

The General Motors Courtesy Transportation program is intended to minimize customer inconvenience when a vehicle requires a repair that is covered by the New Vehicle Limited Warranties. The availability of courtesy transportation to customers whose vehicles are within the warranty coverage period and involved in a product program is very important in maintaining customer satisfaction. Dealers are to ensure that these customers understand that shuttle service or some other form of courtesy transportation is available and will be provided at no charge. Dealers should refer to the General Motors

Courtesy Transportation program is intended to minimize customer inconvenience when a vehicle requires a repair that is covered by the New Vehicle Limited Warranties. The availability of courtesy transportation to customers whose vehicles are within the warranty coverage period and involved in a product program is very important in maintaining customer satisfaction. Dealers are to ensure that these customers understand that shuttle service or some other form of courtesy transportation is available and will be provided at no charge. Dealers should refer to the General Motors Service Policies and Procedures Manual for Courtesy Transportation guidelines.

Service Policies and Procedures Manual for Courtesy Transportation guidelines.

Warranty Transaction Information

| Labor Operation | Description | Labor Time | Trans. Type | Net Item |

| 9100810 | BCM and BPPS Harness and Connector Repair | 0.5 | ZFAT | * |

| 9100822 | Customer Reimbursement Approved

– For USA and Canada dealers only – For Export dealers only |

N/A 0.2 |

ZFAT | ** |

| 9100823 | Customer Reimbursement Denied – For USA dealers only | N/A | ZFAT | *** |

Note: To avoid having to “H” route the customer reimbursement transaction for approval, it must be submitted prior to the repair transaction.

* The amount identified in “Net Item” should represent the actual sum total of the current GMCCA dealer net price for 14 inch Tie Strap, plastic Adhesion Promoter, Dielectric Lubricant and Woven Polyester Electrical Tape needed to perform the required repairs, not to exceed $1.12 USD, $1.20 CAD, plus applicable Mark-Up or Landed Cost (for Export).

** For USA and Canada: Submit the dollar amount reimbursed to the customer in Net/Reimbursement. Submit $20.00 administrative allowance in Net/Admin Allowance.

* The amount identified in “Net Item” should represent the actual sum total of the current dealer net price for the plastic Adhesion Promoter, Dielectric Lubricant and Woven Polyester Electrical Tape needed to perform the required repair, not to exceed 98¢ USD/CAD, plus applicable Mark-Up or Landed Cost (for Export).

** The amount identified in “Net Item” should represent the dollar amount reimbursed to the customer.

For Export: Submit the dollar amount reimbursed to the customer in Net/Reimbursement.

*** Submit $10.00 administrative allowance in Net/Admin Allowance.

Note: Customer reimbursement will not close this recall. The service procedure must also be performed on the vehicle.

Customer Notification – For U.S. and Canada

General Motors will notify customers of this recall on their vehicle (see copy of customer letter included with this bulletin).

will notify customers of this recall on their vehicle (see copy of customer letter included with this bulletin).

Customer Notification – For Export

Letters will be sent to known owners of record located within areas covered by the US National Traffic and Motor Vehicle Safety Act. For owners outside these areas, dealers should notify customers using the attached sample letter.

Dealer Recall Responsibility – For U.S. and Export (U.S. States, Territories, and Possessions)

It is a violation of Federal law for a dealer to deliver a new motor vehicle or any new or used item of motor vehicle equipment (including a tire) covered by this notification under a sale or lease until the defect or noncompliance is remedied.

The US National Traffic and Motor Vehicle Safety Act provides that each vehicle that is subject to a recall of this type must be adequately repaired within a reasonable time after the customer has tendered it for repair. A failure to repair within sixty days after tender of a vehicle is prima facie evidence of failure to repair within a reasonable time. If the condition is not adequately repaired within a reasonable time, the customer may be entitled to an identical or reasonably equivalent vehicle at no charge or to a refund of the purchase price less a reasonable allowance for depreciation. To avoid having to provide these burdensome remedies, every effort must be made to promptly schedule an appointment with each customer and to repair their vehicle as soon as possible. In the recall notification letters, customers are told how to contact the US National Highway Traffic Safety Administration if the recall is not completed within a reasonable time.

Dealer Recall Responsibility – All

All unsold new vehicles in dealers’ possession and subject to this recall must be held and inspected/repaired per the service procedure of this recall bulletin before customers take possession of these vehicles.

Dealers are to service all vehicles subject to this recall at no charge to customers, regardless of mileage, age of vehicle, or ownership, from this time forward.

Customers who have recently purchased vehicles sold from your vehicle inventory, and for which there is no customer information indicated on the dealer listing, are to be contacted by the dealer. Arrangements are to be made to make the required correction according to the instructions contained in this bulletin. A copy of the customer letter is provided in this bulletin for your use in contacting customers. Recall follow-up cards should not be used for this purpose, since the customer may not as yet have received the notification letter.

In summary, whenever a vehicle subject to this recall enters your vehicle inventory, or is in your dealership for service in the future, you must take the steps necessary to be sure the recall correction has been made before selling or releasing the vehicle.

August 2014

Dear General Motors Customer:

Customer:

This notice is sent to you in accordance with the National Traffic and Motor Vehicle Safety Act.

General Motors has decided that a defect which relates to motor vehicle safety exists in 2004-2012 model year (MY) Chevrolet Malibu, 2004-2007 MY Chevrolet Malibu Maxx, 2005-2010 MY Pontiac G6, 2007-2010 MY Saturn Aura vehicles. As a result, GM is conducting a safety recall. We apologize for this inconvenience. However, we are concerned about your safety and continued satisfaction with our products.

has decided that a defect which relates to motor vehicle safety exists in 2004-2012 model year (MY) Chevrolet Malibu, 2004-2007 MY Chevrolet Malibu Maxx, 2005-2010 MY Pontiac G6, 2007-2010 MY Saturn Aura vehicles. As a result, GM is conducting a safety recall. We apologize for this inconvenience. However, we are concerned about your safety and continued satisfaction with our products.

Important:

|

| Why is your vehicle being recalled? | On these vehicles, over time an increased resistance can develop in the Body Control Module (BCM) connection system and result in voltage fluctuations or intermittency in the Brake Apply Sensor (BAS) circuit that can cause service brake lamp malfunction. As a result, the service brake lamps may illuminate when the service brakes are not being applied, or may not illuminate when the service brakes are being applied. Additionally, cruise control may not engage. If cruise control is engaged, additional service brake pedal travel may be required to disengage it. Service brake pedal application may not be required to move the shift lever out of PARK, or additional service brake pedal travel may be required to move the shift lever out of PARK. Traction control, electronic stability control, and panic braking assist features, if equipped, may be disabled. Service ESC and/or Traction Control tell-tales may illuminate with this condition. These conditions may increase the risk of a crash. |

| What will we do? | Your GM dealer will attach your vehicle’s wiring harness to the BCM with a spacer, apply dielectric lubricant to both the BCM and harness connector and on the BAS and harness connector, and relearn the brake pedal home position. This service will be performed for you at no charge. Because of service scheduling requirements, it is likely that your dealer will need your vehicle longer than the actual service correction time of approximately 20 minutes. |

| What should you do? | You should contact your GM dealer to arrange a service appointment as soon as possible. |

| Did you already pay for this repair? | Even though you may have already had repairs for this condition corrected, you will still need to take your vehicle to your dealer for additional repairs. If you have paid for repairs for the recall condition, please complete the enclosed reimbursement form and present it to your dealer with all required documents. Working with your dealer will expedite your request, however, if this is not convenient, you may mail the completed reimbursement form and all required documents to Reimbursement Department, PO Box 33170, Detroit, MI 48232-5170. The completed reimbursement form and required documents must be presented to your dealer or received by the Reimbursement Department by August 31, 2015, unless state law specifies a longer reimbursement period. |

| Do you have questions? | If you have questions or concerns that your dealer is unable to resolve, please contact the appropriate Customer Assistance Center at the number listed below. |

| Division | Number | Text Telephones (TTY) |

| Chevrolet | 1-800-222-1020 | 1-800-833-2438 |

| Pontiac | 1-800-762-2737 | 1-800-833-7668 |

| Saturn | 1-800-553-6000 | 1-800-833-6000 |

| Guam | 65-6267-1752 | |

| Puerto Rico – English | 1-800-496-9992 | |

| Puerto Rico – Español | 1-800-496-9993 | |

| Virgin Islands | 1-800-496-9994 |

If after contacting your dealer and the Customer Assistance Center, you are still not satisfied we have done our best to remedy this condition without charge and within a reasonable time, you may wish to write the Administrator, National Highway Traffic Safety Administration, 1200 New Jersey Avenue, SE, Washington, DC 20590, or call the toll-free Vehicle Safety Hotline at 1.888.327.4236 (TTY 1.800.424.9153), or go to https://www.safercar.gov. The National Highway Traffic Safety Administration Campaign ID Number for this recall is 14V252.

Federal regulation requires that any vehicle lessor receiving this recall notice must forward a copy of this notice to the lessee within ten days.

Jim Moloney

General Director,

Customer and Relationship Services

Enclosure

GM Recall Number: 13036

Q&A Document for Upcoming Safety Recall 13036

Brake Lamps Malfunction

Q1. What vehicles are involved?

A1. All 2004-2012 model year (MY) Chevrolet Malibu, 2004-2007 MY Chevrolet Malibu Maxx, 2005-2010 MY Pontiac G6 and 2007-2010 MY Saturn Aura vehicles.

Q2. What is the condition being covered?

A2. On these vehicles, over time an increased resistance can develop in the Body Control Module connection system and result in voltage fluctuations or intermittency in the Brake Apply Sensor circuit that can cause service brake lamp malfunction. As a result, the service brake lamps may illuminate when the service brakes are not being applied, or may not illuminate when the service brakes are being applied. Additionally, cruise control may not engage. If cruise control is engaged, additional service brake pedal travel may be required to disengage it. Service brake pedal application may not be required to move the shift lever out of PARK, or additional service brake pedal travel may be required to move the shift lever out of PARK. Traction control, electronic stability control, and panic braking assist features, if equipped, may be disabled. Service ESC and/or Traction Control tell-tales may illuminate with this condition. These conditions may increase the risk of a crash.

Q3. How will you repair these vehicles?

A3. To correct these conditions, dealers are to attach the wiring harness to the BCM with a spacer, apply dielectric lubricant to both the BCM and harness connector and on the BAS and harness connector, and relearn the brake pedal home position.

Q4. How did you discover the condition?

A4. Customer complaints and warranty claims.

Q5. Have there been any reports from the field of crashes or injuries related to this condition?

A5. GM is aware of 13 crashes and two injuries, but no fatalities as a result of the condition.

Q6. Why are we recalling these vehicles now after the actions taken in 2009?

A6. Based on data gathered through additional investigation and field evaluation process it was determined that these vehicles may have the same condition as those vehicles involved in a safety recall in 2009.

Q7. Did NHTSA pressure us to do this recall?

A7. There was a NHTSA and Transport Canada investigation on this issue.

Q8. Where were these vehicles made?

A8. Chevrolet Malibu – Fairfax, Kan. and Orion Township, Mich.

Pontiac G6 – Orion Township, Mich.

Saturn Aura – Fairfax, Kansas

Q9. Where besides the United States were these vehicles sold?

A9. Aruba, Bahamas, Bahrain, Brazil, Canada, Cayman Islands, Guam, Israel, Jordan, Kuwait, Lebanon, Mexico, Netherland Antilles, Oman, Palestinian Territories, Panama, Qatar, Saudi Arabia, United Arab Emirates and Yemen (U.S. – 2,440,524, Canada – 194,314, Exports – 68,819)

Q10. Is my vehicle safe to drive?

A10. The condition may not appear in all vehicles. A quick check can be applied to see if your brake lights are illuminated when the brake pedal is pressed.

Q11. When will I be able to get my vehicle repaired and how much will it cost me?

A11. Customer advisory letters will be sent soon followed by a second letter informing customers that they can call for appointments to have their vehicles’ serviced. Repairs will be performed at no cost to customers.

Q12. I’ve had my vehicle repaired. When can I be reimbursed?

A12. The new service procedure is more comprehensive and we would like to fully service the vehicle. If the customer has paid for the repairs with dielectric grease for the brake lights, we will reimburse them with their receipt.

23 Affected Products

Vehicles

| CHEVROLET | MALIBU | 2004-2012 |

| CHEVROLET | MALIBU MAXX | 2004-2007 |

| PONTIAC | G6 | 2005-2010 |

| SATURN | AURA | 2007-2010 |

25 Associated Documents

Manufacturer Notices(to Dealers,etc) – Notice regarding Q&A

To View or Download this Document Click Here

Loading...

Loading...

Other Recall Related Documents – Q&A

RCORRD-14V252-7289.pdf 60.544KB

Loading...

Loading...

Defect Notice(Part 573) Supplemental

RCDNN-14V252-4539.pdf 98.861KB

To View or Download this Document Click Here

Loading...

Loading...

Owner Notification Letter(Part 577)- Interim

RCONL-14V252-8202.pdf 162.373KB

To View or Download this Document Click Here

Loading...

Loading...

Recall Acknowledgement

Loading...

Loading...

Manufacturer Notices(to Dealers,etc)

To View or Download this Document Click Here

Loading...

Loading...

Recall Quarterly Report – 2015-Q1

RCLQRT-14V252-3479.PDF 29.081KB

Loading...

Loading...

Renotification Notice

To View or Download this Document Click Here

Loading...

Loading...

Manufacturer Notices(to Dealers,etc)

To View or Download this Document Click Here

Loading...

Loading...

Remedy Instructions and TSB

RCRIT-14V252-3751P.pdf 750.355KB

To View or Download this Document Click Here

Loading...

Loading...

Defect Notice(Part 573)

RCDNN-14V252-1248P.pdf 128.369KB

To View or Download this Document Click Here

Loading...

Loading...

Remedy Instructions and TSB – Bulletin No.: 13036A Date: July 2015

RCRIT-14V252-1836.pdf 958.06KB

To View or Download this Document Click Here

Loading...

Loading...

Manufacturer Notices(to Dealers,etc)

To View or Download this Document Click Here

Loading...

Loading...

Recall Quarterly Report – 2015-Q2

RCLQRT-14V252-3991.PDF 29.183KB

Loading...

Loading...

Remedy Instructions and TSB – Bulletin No.: 13036B Date: September 2015

RCRIT-14V252-6894.pdf 1118.999KB

To View or Download this Document Click Here

Loading...

Loading...

Recall Quarterly Report – 2015-Q4

Loading...

Loading...

Recall Quarterly Report – 2015-Q3

RCLQRT-14V252-3290.PDF 29.307KB

Loading...

Loading...

Manufacturer Notices(to Dealers,etc) – Part Information and Service Procedure Revised

To View or Download this Document Click Here

Loading...

Loading...

Owner Notification Letter(Part 577)

RCONL-14V252-0123P.pdf 163.086KB

To View or Download this Document Click Here

Loading...

Loading...

Recall Quarterly Report – 2014-Q4

RCLQRT-14V252-8014.PDF 28.94KB

Loading...

Loading...

Recall Quarterly Report

RCLQRT-14V252-1056.pdf 28.934KB

Loading...

Loading...

Safety Bulletin

RCSB-14V252-9329.pdf 1587.134KB

To View or Download this Document Click Here

Loading...

Loading...

Manufacturer Notices(to Dealers,etc)

To View or Download this Document Click Here

Loading...

Loading...

Safety Bulletin

RCSB-14V252-1437.pdf 1586.539KB

To View or Download this Document Click Here

Loading...

Loading...

Manufacturer Notices(to Dealers,etc)

To View or Download this Document Click Here

Loading...

Loading...

1 Associated Investigation

Brake Light Switch/Sensor Malfunction

NHTSA ID: EA13005

Dated opened: June 6, 2013

On May 14, 2014 General Motors (GM) announced a recall action (14V-252) involving model year (MY) 2004-12 Chevrolet Malibu, MY 2004-07 Malibu Maxx, MY 2005-10 Pontiac G6 and MY 2007-10 Saturn Aura vehicles. An increased resistance can develop in the Body Control Module connection systems and result in voltage fluctuations in the Brake Apply Sensor (BAS, or brake light switch) circuit that can cause the brake lamps to malfunction. As a result, and according to GM, the brake lamps may illuminate when pedal application is not being applied or may not illuminate when pedal force is applied. Additionally, the cruise control may not engage or if it is engaged it may require increased pedal travel to disengage. Pedal application may not be required to move the shift lever out of PARK or additional travel may be required to move the shift lever out of PARK. Traction control, electronic stability control (ESC) and panic brake assist features may also become disabled. These failure conditions may increase the risk of a crash.

The Office of Defects Investigation (ODI) opened Engineering Analysis EA13-005 on June 6, 2013 to further investigate complaints alleging that the brake lights did not operate properly on MY 2005-08 Pontiac G6 vehicles. The BAS in these vehicles produces a single analog voltage output proportional to the brake pedal’s position. The BAS signal is used by various systems to determine both pedal position and rate of displacement, so a failure or inaccuracy of the signal may affect multiple systems. ODI also received similar complaints on MY 2009 Pontiac G6, MY 2004-11 Chevrolet Malibu and MY 2007-09 Saturn Aura vehicles that use the same BAS. All of these above models were included in the subject vehicle population of ODI’s Information Request (IR) letter to GM. Prior to the recall announcement date, ODI received 855 reports of brake light malfunction resulting in one or several of the failure conditions. Eight (8) of the reports alleged crashes, with 1 resulting in an injury. Of these crash allegations, 2 were roll-away incidents, in which the shift interlock was moved out of PARK without pedal application and the vehicle rolled into another object. Three (3) crashes involved rear-end hits, which were believed to be due to brake light reversal. ESC/Traction Control failures were the alleged cause of 2 incidents, which resulted in unresponsive brake application and in 1 case caused the vehicle to leave the roadway. One (1) crash allegation was not counted as the circumstances of the crash were not related to any of the failure modes. ODI notes that it is difficult to determine the actual cause of incidents where brake light reversal or ESC/Traction Control failures were the alleged cause.

In response to ODI’s IR, GM submitted 2,268 unique reports that related to brake lamp malfunction. Combined with the data submitted during Recall Query 13-001, a total of 4,664 unique complaints were submitted. Twelve (12) of the GM reports alleged a crash, with 2 reporting minor injuries and 4 alleging property damage. Of the 12 reports, 3 involved brake light reversal allegations, 4 involved roll-away incidents and 2 involved ESC/Traction Control malfunctions. ODI did not include three (3) reports that involved allegations inconsistent with the alleged defect.

This investigation is closed on the basis of GM’s announcement of safety recall 14V-252.

The ODI complaints cited above can be reviewed at: https://www-odi.nhtsa.dot.gov/owners/SearchNHTSAID, see the attached list for ODI numbers.

Latest Recalls Documents

| “This site contains affiliate links for which OEMDTC may be compensated” |

- Seal Out Moisture and Corrosion From the Elements - Permatex Dielectric Grease Protects Terminals, Wiring, and Other Electric Connections From Salt, Dirt and Corrosion

- Keep Your Electrical Connections Safe - Seal, Lubricate and Insulate to Prevent Various Leaks or Damage Around Any Electrical Connection Ensuring Top Performance and Vehicle Quality

- High Performance Dielectric Tune-Up Grease Helps Extend the Life of Bulb Sockets, Ignition Coil Connectors, and Electric Connections Within Your Battery

- Required For Modern, High Energy Ignition - Permatex Dielectric Tune-Up Grease Ensures Automotive Performance, Extended Lifetime and Corrosion Prevention Within Electrical Systems

- Suggested Applications - Permatex Dielectric Tune-Up Grease is Appropriate For Spark Plug Boots, Trailer Hitches, Battery Terminals, and All Other Electrical Connections

- Secure Electrical Connections: Seal, lubricate and insulate to prevent various leaks or damage around any electrical connectors ensuring top performance and vehicle quality(Dieletric Breakdown 10KVA)

- Anti Corrosion: Designed with outstanding oxidation and corrosion resistance to keep all electrical components insulated over long periods of time. This grease is multi-surface friendly and safe to use on rubber, plastic, and ceramic surfaces

- Required For High Energy Ignition: BTAS die electric silicone grease ensures automotive performance, extended lifetime and corrosion preventer with in electrical systems

- Superior Temperature Performance: Ultra high and low temperature environments are no match for BTAS dialectic contact grease. This high-performance dialectric silicone grease is designed to handle operating temperatures of -40° to +428°F

- Suggested Applications: BTAS di electrical grease is appropriate for automotive electrical connectors,battery terminals, spark plug boots, and all other electrical connectors

- Premium Silicone Paste: This Brush Top Can contains 4oz of premium silicone paste, ideal for automotive and electrical applications. It serves as an excellent electric grease, protecting components from moisture and corrosion effectively.

- Versatile Electrical Grease: Our silicone paste functions as superior electrical grease, suitable for use as spark plug grease. It ensures optimal performance of spark plug connections, enhancing efficiency and longevity.

- Dielectric Grease for Automotive: The dielectric grease spark plug formulation is perfect for automotive needs, providing exceptional insulation. As die-electric grease automotive, it shields electrical connections from harmful elements.

- Battery Terminal Grease: Use this conductive grease for electrical connections like battery terminals. The silicone paste automotive grade enhances conductivity, while preventing oxidation, ensuring reliable power transfer and extended battery life.

- Effective Electrical Grease: As electrical grease for connectors, this product acts as conductive grease, securing tight electrical connections. The dialectical grease properties make it indispensable for maintenance, ensuring long-lasting, efficient performance.

Grease for Electrical Connectors Automotive, Dialectric Grease with a Brush, Spark Plug, O Rings, Marine Waterproof & Heat-Resistant & Insulating 1oz (1pcs)" title="13036 Product Safety Recall - Brake Lamp Malfunction - 2004-2012 Chevrolet Pontiac Saturn 8">

Grease for Electrical Connectors Automotive, Dialectric Grease with a Brush, Spark Plug, O Rings, Marine Waterproof & Heat-Resistant & Insulating 1oz (1pcs)" title="13036 Product Safety Recall - Brake Lamp Malfunction - 2004-2012 Chevrolet Pontiac Saturn 8">

- Secure Electrical Connections: Our dielectric grease has excellent insulation properties, which can effectively prevent various leakage and damage, such as short circuits and arcs, in electrical connectors, ensuring the reliability and efficiency of various electrical applications

- Waterproof and Anti-corrosion: Our dielectric grease for electrical connectors can prevent substances such as dust and moisture from entering the electrical connection, keeping all electrical components insulated for a long time and preventing metal surfaces from corrosion. It is an ideal choice for outdoor and humid environments

- Excellent Temperature Performance: This silicone grease is resistant to high temperatures, oxidation, and decomposition. This dialectric grease can also maintain continuous lubrication in high-temperature environments. It can not only ensure the performance of the car but also extend the service life of the machinery. Temperature range: -50℃ to 200℃

- Multi-purpose Application: This dielectric grease automotive can be used as a silicone paste with excellent results. It is widely used in electrical equipment and electronic components such as cable connectors, plugs, switches, automotive ignition systems, spark plugs, brake caliper pins, battery terminals & bulbs

- Satisfaction Guarantee: If you are not satisfied with our spark plug grease, please feel free to contact us. We will respond to your confusion and dissatisfaction sincerely and positively. Our job is to ensure that customers are satisfied with their purchases

- Package length: 2.032 cm

- Package width: 2.54 cm

- Package height: 20.066 cm

- Product Type: AUTO ACCESSORY

- Stop Electrical Faults & Failures: AGS Automotive Solutions' Dielectric Silicone Grease effectively prevents electrical problems by shielding against corrosion and water damage. Easy to apply, it ensures secure connections in just a few seconds.

- Meets OEM Specifications: The unique estrous formula of this grease meets all OEM standards, providing an additional layer of protection and preventing mis-readings in electrical connections.

- Ideal for Big Jobs: Each tube contains .5 oz. of grease, making it suitable for demanding applications. It's perfect for use on sensor connections, computer connections, solenoids, truck pigtails, plugs, and ignition modules.

- Rust-Free Connections: Protect your engine and electronics from rust with this grease. Its application takes only a few seconds, offering long-lasting protection against corrosion.

- Versatile and Reliable: This dielectric silicone grease is a versatile solution for various automotive needs, ensuring reliability and peace of mind in maintaining the integrity of your vehicle's electrical connections.

- ALL PURPOSE CLEANERS

- AUTO_PART

- 3.3 oz

- Package Dimensions: 4.064 L x 24.13 H x 4.064 W (centimeters)

- Superior Insulation Performance: Are you worried that electrical components and connectors are not safe to use? Our dielectric grease boasts excellent insulation properties, effectively preventing short circuits and electrical arcs at connections, ensuring reliability and efficiency in a wide range of electrical applications

- High Temperature and Oxidation Resistance: This dielectric grease for electrical connectors remains stable in high-temperature conditions, resisting oxidation and decomposition. Silicone grease thermal stability ensures consistent lubrication at high temperatures, prolonging the lifespan of your equipment. Temperature Range: -50℃ to 200℃

- Waterproof and Corrosion Resistant: With outstanding waterproof capabilities, dielectric grease prevents moisture, dust, and other contaminants from entering electrical connections. Silicone Paste effectively protects metal surfaces from corrosion, making it ideal for outdoor and humid environments

- Multi-purpose application: It works excellently as a silicone grease and is widely used in the maintenance of various electrical equipment and electronic components, such as cable connectors, plugs, switches, automotive ignition systems, spark plugs, brake caliper pins, etc

- Satisfaction Guarantee: If you are not satisfied with our dielectric grease, please contact us in your free time. You will get our sincere and positive response. Our job is to ensure that our customers are satisfied with their shopping

- Protect Battery Terminals & Connectors: Shield your car’s battery terminals and electrical connections from moisture, salt, and corrosion. Seal, lubricate and insulate to prevent leaks and damage, ensuring top performance and vehicle quality.

- Perfect for Spark Plugs: Extend the life of spark plugs, bulb sockets, and ignition coils with this non-conductive grease. It prevents arcing and corrosion for optimal engine performance.

- Withstands Extreme Temperatures: Built to withstand freezing winters and scorching summers, this grease stays effective from -40°F to 428°F, ensuring year-round protection.

- Waterproof & Corrosion-Resistant: Prevent rust and corrosion with this durable, waterproof formula. Ideal for vehicles exposed to rain, snow, or coastal environments.

- Easy to Apply, Long-Lasting: Its smooth, non-drying formula is easy to apply and provides long-lasting protection, reducing maintenance and saving you time.

- Mess-Free Application: Experience a mess-free application with our 4oz Brush Top Can, designed for precision and ease of use. This die electric grease ensures clean and efficient application, ideal for various automotive and electrical tasks.

- Superior Electrical Protection: Our dielectric grease provides excellent protection against moisture and corrosion, enhancing the performance of spark plug grease and electrical grease for connectors. It's perfect for maintaining optimal electrical connections.

- Versatile Usage: This dialectical grease is perfect for a broad range of applications, from bulb grease to die electric grease automotive uses, ensuring your electrical systems remain in top condition. The grease protects and prolongs the lifespan of components.

- Enhanced Conductivity: Improve conductivity and prevent oxidation with our battery terminal grease. Ideal for car battery terminal grease and electrical contact grease, it ensures reliable performance in both automotive and electrical systems.

- Long-Lasting Protection: Our dielectric silicone grease offers durable, long-lasting protection against environmental factors. It's an excellent choice for dielectric grease spark plug applications and conductive grease for electrical connections.

Last update on 2025-05-08 / Affiliate links / Images from Amazon Product Advertising API

This product presentation was made with AAWP plugin.