| “This site contains affiliate links for which OEMDTC may be compensated” |

NHTSA ID Number: 10115089

Manufacturer Communication Number: PIT5476

Summary

This Preliminary Information communication provides information to the technician about vehicles that may have rough harsh ride. Technician will need to use the Pico Oscilloscope to evaluate the vehicle. If a rough/harsh/stiff ride has been determined to be the customer’s concern, following evaluation using the Pico Oscilloscope, then replace the complete front suspension shock with coil spring assemblies, and rear shocks with updated parts and reprogram the Suspension Control Module with updated calibrations available in TIS2WEB.

2 Affected Products

Vehicles

Parts

| Front | ||||

| Spring Asm-Frt Coil (w/ Shock) | C15543, C15743 | 6NA, 7NA, 6NB, 7NB | 1 side | 23317172 |

| Spring Asm-Frt Coil (w/ Shock) | C15543, C15743 | 6NC, 7NC | 1 side | 23317173 |

| Spring Asm-Frt Coil (w/ Shock) | K15543, K15743 | 6ND, 7ND, 6NT, 7NT, 6NU, 7NU | 1 side | 23317176 |

| Spring Asm-Frt Coil (w/ Shock) | K15543, K15743 | 6PA, 7PA | 1 side | 23317177 |

| Rear | ||||

| Absorber Asm-Rr Lvlg Shock | ALL | ALL | 1 Side | 23314866 |

SEOCONTENT-START

| Subject: | Rough Harsh Ride |

| Models: | 2015 GMC Sierra 1500 Denali |

| With Magnetic Ride Control Suspension (RPO Z95) | |

| Vehicles Built Before 2/24/2015 | |

| Attention: | Installing the updated suspension components and calibration will NOT provide a ‘sofa-on-wheels’ type of ride, and will NOT eliminate tire/wheel, propshaft, rear axle related inputs/disturbances; they are designed specifically to address the rough, harsh rough/harsh/stiff ride concern. |

The new 2015 Full-Size LD Denali Pickup incorporates suspension design improvements for improved handling, decreased stopping distances, reduce body roll, etc.

Many customers are very satisfied with the ride and handling, but some owners may feel the ride is not to their satisfaction.

They may comment of a rough/harsh/stiff ride, or they may describe a vehicle vibration with a similar description.

Typically, this condition is most noticeable between 35-55 mph on fairly smooth roads, when coming in contact with small/minor road imperfections/bumps, expansion joints, etc.

The suspension will absorb larger bumps without complaints, but smaller/minor imperfections/bumps, which would normally be absorbed by the suspension, may not be absorbed as well as the owner would expect.

Recommendation/Instructions

Evaluate the vehicle using the vibration analyzer CH-51450-A (Pico Oscilloscope), driving the vehicle in 35-55 mph range on the same section of road for each stage of evaluation.

Pico scope will normally show this ride condition as a Tire 2 or Unknown vibration (approximately 15-19 Hz) in response to small/minor road imperfections/bumps. The vibration analyzer should be used twice:

1st to determine the customer concern is a rough/harsh/stiff ride and 2nd after the repairs to verify the cause is repaired and to identify if other inputs / disturbances are present.

The Hz and Mg readings should be documented using the Z95 rough/harsh/stiff ride / vibration chart below.

Important: When using the vibration analyzer make sure to obtain readings after the vehicle has been driven at least 10-15 miles to warm up the tires and cycle the new shocks. After new shocks are installed they will need to be cycled before optimum ride is obtained, which is done during normal driving.

[During evaluation, position the Pico accelerometer sensor to capture Both vertical and horizontal planes, for tri-axis sensor, ensure correct orientation for X, Y, and Z axis. Place the sensor on the seat track, console, steering column, etc. If additional sensors are used, place at each vehicle corner to help narrow area of strongest input/disturbance.]

If a rough/harsh/stiff ride has been determined to be the customer’s concern, following evaluation using the Pico scope, then replace the complete front suspension shock with coil spring assemblies, and rear shocks with updated parts and reprogram the Suspension Control Module (K19) with updated calibrations available in TIS2WEB. (The calibration may be labeled “Real Time Damping.”) The updated part numbers listed below utilize various improvements to address the ride concern as described.

Note: Vehicle alignment does not need to be adjusted as a result of the Z95 MR suspension component updates.

Please note that this rough/harsh/stiff ride / vibration condition can be magnified by other inputs/disturbances which may be present, such as: Tire and wheel assemblies with excessive road force variation (RFV), propshaft balance / runout, and/or rear axle pitchline runout related issues. These updated suspension components will Not correct these other inputs/disturbances, which Must be addressed separately. If an issue in any of these other areas is found, it should be corrected Before returning the vehicle to the customer, See the latest version of PI1354 to work through other inputs/disturbances.

Following Z95 MR-related updates, re-evaluate the vehicle to ensure no other inputs/disturbances are present. If other inputs/disturbances are present, review the additional diagnostic tips in this PI and correct the remaining conditions:

Additional Diagnostic Tips

Ensure tire and wheel assemblies are not contributing to the issue.

Keep in mind this rough ride issue will often show up as T2 in response to road input, (suspension reacting to road input, rather than absorbing it).

If T1 is present, or any higher order, other than some T2 in direct-response to road input, expansion joints, etc. the tire and wheel assemblies must be investigated.

There have been some cases of T2 tire issues, some high-speed RFV issues (primarily with the 22-inch tires), and some cases of tire/wheel assemblies showing acceptable RFV numbers, but with further investigation, have been found to have bent inboard rim flanges with hidden tire damage, visible inside when dismounted.

The GSP9700 checks tire low-speed RFV only, in the radial plane only.

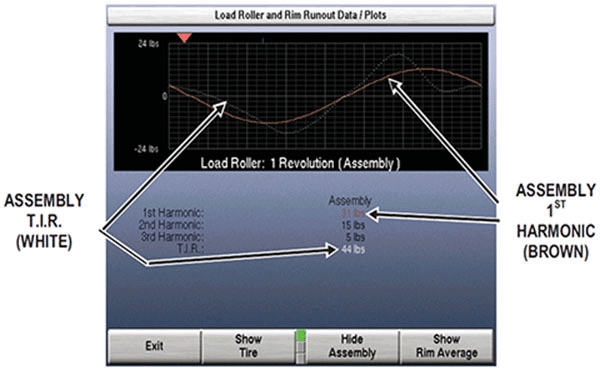

The GSP9700 is set to display T1 RFV. Higher order RFV, T2 & T3 can be displayed in the Assembly Data Plots Screen, as shown above.

Depending on the level of GSP9700, the screen may be under ‘Data’ or ‘Runout Plots,’ then “Rim and Load Roller Runout Plots.”

When checking tires on the GSP9700, if (radial) T2 is high or close to the (radial) T1 value, the tire should be replaced. As an example, if a tire and wheel assembly is measuring T1 at 10 lbs RFV, the tire would be considered good; however, if in displaying the higher orders, it is found that the tire and wheel assembly also has T2 at say 9 lbs RFV, the tire needs to be replaced. Refer to the latest version of PI1354 for latest procedures.

Road Force Variation (RFV) Specification to Address Ride Concerns

P-Metric Tires on Light Trucks, SUVs

Note: Arrange the tires on the vehicle in the following order: lowest RFV at LF, next RF, next LR, highest RR

- Propeller Shaft

Ensure the propshaft is not contributing to the issue. If any orders of P measured with significance on the Pico in vertical or horizontal planes – inspect the propshaft for dents or other damage. If no damage is present, check propshaft balance and runout, refer to the latest version of “Vibration Analysis And Diagnostic” for latest procedures. Remember to consider and inspect the transmission output shaft bushing for irregular wear.

- Rear Drive Axle

Ensure the rear drive axle is not contributing to the issue. Pitchline runout / gear set machining, followed by setup issues have been found to be contributors to vibration issues; not just whine noise concerns. Gear set machining issues in these axles seem to most often show up as P1 or higher order P related; with some showing as T1 or higher order of T related; all depending on gear set condition.

If tire/wheel assemblies and propshaft have been ruled out / repaired, and P1, T1 or a higher order of P or T is still present in the vertical or horizontal plane – other than in direct-response to road input, the drive axle must be investigated

Check for pitchline runout and setup issues, refer to the latest version of “Vibration Analysis And Diagnostic” for latest procedures.

If drive axle repair is necessary, we have heard some reports that during repair, tooling chatter marks may be observed in the pinion race counterbores. This issue lends to the idea that the races may not be fully seated until some vehicle use is introduced into the axle. This issue would most often result in a noise concern, though severe loss of preload might produce a vibration. The races should be able to be fully seated during repair.

Parts Information

| Part Number | Description | Vehicle Model | Spring Code | Qty |

| Front | ||||

| Note: Verify spring code RPOs, LH and RH for vehicle from the SPID label or IVH/GWM. Some vehicles by-design will have LH / RH spring codes which fall into different groupings / different part numbers for each side – they must be serviced in the same manner to best address this ride concern. For example: A truck with LH spring code of 6NC, with RH spring code of 7NB would use 23317173 for the Left side and 23317172 for the Right side. | ||||

| 23317172 | Spring Asm-Frt Coil (w/ Shock) | C15543, C15743 | 6NA, 7NA, 6NB, 7NB | 1 side |

| 23317173 | Spring Asm-Frt Coil (w/ Shock) | C15543, C15743 | 6NC, 7NC | 1 side |

| 23317176 | Spring Asm-Frt Coil (w/ Shock) | K15543, K15743 | 6ND, 7ND, 6NT, 7NT, 6NU, 7NU | 1 side |

| 23317177 | Spring Asm-Frt Coil (w/ Shock) | K15543, K15743 | 6PA, 7PA | 1 side |

| Rear | ||||

| 23314866 | Absorber Asm-Rr Lvlg Shock | ALL | ALL | 1 Side |

SEOCONTENT-END

Bulletin No.: PIT5476

Date: Nov-2015

To View or Download this Document Click Here

Loading...

Loading...

Reprogramming

GM Diagnostic/Programming (TIS2Web)

Approved J2534 Device with TIS2WEB can reprogram 1996 and later All GM Modules.

To obtain the latest electronic controller calibration information for your vehicle, go to https://tis2web.service.gm.com/tis2web and enter the vehicle's 17 character Vehicle Identification Number (VIN) and select 'Get CAL ID’.

You can then compare the latest part number with the actual number installed on the vehicle to determine if a reprogram is needed.

The Service Programming System (SPS) application is part of the TIS2Web system. To program an ECU, the SPS application must communicate with the vehicle control modules using the proper J2534 programming interface tool.

The following are the supported interface tools:

The Tech 2 supports model years 1996 and beyond. With the addition of the CAN Diagnostic Interface (CANdi) module, Tech 2 is fully backward compatible with current Tech 2 functionality and operates transparently when diagnosing non-CAN-equipped vehicles.

Servicing the next generation Global A vehicles will require the diagnostic software, GDS2, Global Diagnostic System 2 running on a local PC device while the MDI is connected to the vehicle. The GM MDI is the Global Diagnostic tool for future vehicles starting with Global A vehicles.

The GM MDI was introduced in the fall of 2007 for Pass-Thru programming and offers faster programming speed. It can be used to perform Pass-Thru programming on all vehicles built since 1996 and into the future. Click here to view a list of GDS supported vehicles.

- J2534 Pass-Thru Programmer: TOPDON RLink J2534 is an advanced diagnostic and reprogramming tool that support all J2534 protocols, as well as D-PDU, CAN-FD and DoIP, ensuring compatibility with a wide range of modern vehicles. It offers extensive versatility with support for over 17 major automotive brands, including Chrysler, Ford

, GM, Nissan

, GM, Nissan , Toyota

, Toyota , Honda, Subaru

, Honda, Subaru , Land Rover/Jaguar, Volvo, Wuling, Volkswagen, Mercedes-Benz, and BMW, and so on, enjoy dealership-level functions at your fingertips

, Land Rover/Jaguar, Volvo, Wuling, Volkswagen, Mercedes-Benz, and BMW, and so on, enjoy dealership-level functions at your fingertips - All-in-One OEM Diagnostics: This J2534 ECU programming tool elevates your automotive repair capabilities to new heights by delivering complete OEM diagnosis. Boasting comprehensive full-system diagnostics, intuitive repair guides, advanced ECU programming and coding, common reset services, a vast library of repair information and more, this all-in-one solution empowers technicians to effortlessly tackle complex vehicle issues with ease

- Proven Performance You Can Trust: Backed by over 10000 real vehicle tests and benefit from a wealth of practical experience, this OEM reprogramming tool guarantees stable and exceptional performance. Supported by TOPDON's dedicated technical experts with in-depth knowledge of both auto repair and J2534 Pass-Thru programming, the RLink J2534 provides prompt and professional assistance, ensuring a smooth setup and reliable compatibility

- Integrated Excellence, Always Up-to-Date: Featuring the exclusive RLink Platform to provide a streamlined experience with one-click driver installation and management, ensuring flawless integration with your OE software, maintaining the original performance quality. The built-in operation guide makes mastering OE software quick and easy, so you can get started right away. Plus, with lifetime free updates, your diagnostics will stay current with the latest drivers and innovations

- Efficiency Meets Versatility: Engineered to support three CAN channels simultaneously - CAN FD and CAN-CC included, giving you the edge in fast troubleshooting. To perfectly synchronized with the OE software, please diagnose with active subscriptions and make sure your computer system is running a compatible 64-bit Windows version (7, 8, 10 or later) to fully leverage the power of RLink J2534. *We don't provide extra OE software

- 【J2534 PROTOCOL WITH SMARTLINKC】 LAUNCH X431 PRO3S+ ELITE scan tool with newly upgraded smartlinkC V2.0. The SmartLinkC is a communication interface supporting J2534 specifications. Of course, it also can be used as a J2534 PassThru device, working together with the PC installed with the OEM diagnostic software to perform the J2534 protocol.J2534 protocol is the only solution for problems ranging from driveability and loss of power to poor fuel economy.

- 【INTELLIGENT TOPOLOGY MAP TO FASTER FULL SYSTEMS DIAGNOSIS】 X431 PRO3S+ELITE bidirectional scan tool with new-added intuitive topology mapping. Harnesses intuitive topology mapping for comprehensive visualization of the vehicle all system. It shows all available control units in different colors, the numbers of system, the scanned system, and the scan results, bringing maximum convenience & superfast speed for you to do swift diagnosis & high-level repairs.

- 【TOP HARDWARE CONFIGURATION, UPGRADED OF LAUNCH X431 PRO3S+】 LAUNCH X431 PRO3S+ELITE diagnostic scanner possess with Android 10.0 OS; CPU 4-Core Processor, 2.0 GHz. Greatly increased the speed of running multiple task. 2.4GHz/5GHz; 6300mAh/7.6V stronger battery capacity; 10.1 Inch Touchscreen with 8MP camera; AUTO VIN; 4GB+64GB storage memory; 20X faster transmission rate, save more vehicle documents and customer data; Supports 25+ Software Languages, such as EN, DE, FR, SP nd JP and so on.

- 【3000+ ACTIVE TEST/BI-DIRECTIONAL CONTROL LAUNCH SCANNER】 LAUNCH X431 PRO3S+ELITE HD automotive scanner is a cost-effective bidirectional scanner that deserves owned by every repairing DIYers and mechanics. You can easily send command signal at fingertips from the scanner to various module actuators to test component integrity and functionality in minutes or even seconds to tell if replacement or repair is needed.

- 【COMPLETE 60+ HOT RESETS, CALIBRATION, INITIALIZATION, RELEARN】 LAUNCH X431 PRO3S+ELITE SmartLinkC escaner automotriz professional enjoys 60+ special service, such as Oil Reset, ABS brake bleed, EPB, SAS, BMS, Suspension, Injector reset, Power Balance, Turbo Calibration, VGT, Transmission Adaption, Throttle Adaptation, matching and etc. rigorous on-site testing has been performed to ensure 100% availability.

- 🌐【Works with Autel Elite II Elite MS908 MS908S Pro II MS908CV II MK908P MK908 Pro II】Autel J2534 work with these tools to program ECUs on specific BM.W/ BE.NZ for specific functions. ★★NOTE: J2534 CANNOT directly work with these single devices. After you received the J2534, you HAVE TO send us both the S/N(12 digits) of your scanner MS908S(etc.) and J2534. So, technically, Autel engineers can help you bind J2534 with your devices. If need any supports, contact us via: 🚘auteldirect @ outlook. com🚘.

- 🌐【SAE J2534-1 & J2534-2 Standards】Autel MaxiFlash Elite J2534 is a fully compliant SAE J2534-1 & SAE J2534-2 (March 2006) device, which performs standard PassThru J2534 functionality: Compatible with for Toyota

Techstream, Volvo VIDA, Honda HDS, Jaguar-Land Rover IDS and BM.W 3G for OEM diagnostics. Autel MaxiFlash J2534 is also specially designed to provide users with P-C communication and ECU reprogramming capabilities on any modern vehicle diagnostic bus, reliability and flexibility.

Techstream, Volvo VIDA, Honda HDS, Jaguar-Land Rover IDS and BM.W 3G for OEM diagnostics. Autel MaxiFlash J2534 is also specially designed to provide users with P-C communication and ECU reprogramming capabilities on any modern vehicle diagnostic bus, reliability and flexibility. - 🌐【High-speed Transmission Speed】Autel MaxiFlash Elite Reprogramming Device J2534 supports simultaneous communication definition in J2534-1, running 3 protocols at the same time, which greatly improves reprogramming and diagnostic speed. Embedded with the ARM9 Dual-core processor (clocked up to 500MHz), which further boosts the communicating speed to save more times and win more business.

- 🌐【Multiple Devices Connected with P-C】Autel MaxiFlash Elite J2534 also supports multiple device connections to the P-C, which can operate diagnostic and reprogramming functions on more than one vehicle at the same time. Autel MaxiFlash Elite J2534 built-in wireless and data storage, which can update via Internet. It also ensures quickly reprogramming even the newest controllers.

- 🌐【Extensive Compatibility】Autel MaxiFlash J2534 is compatible with Toyota

Techstream, Volvo VIDA, Honda HDS, Jaguar-Land Rover IDS and BM.W 3G for OEM diagnostics. To check compatibility, please contact 🚘auteldirect @ outlook . com🚘 directly for satisfaction-guaranteed support!

Techstream, Volvo VIDA, Honda HDS, Jaguar-Land Rover IDS and BM.W 3G for OEM diagnostics. To check compatibility, please contact 🚘auteldirect @ outlook . com🚘 directly for satisfaction-guaranteed support!

- ALL OF THE J2534 PROTOCOLS - This single unit has all of the protocols you need for your OEM J2534 reprogramming and diagnostics including the latest in DoIP and CanFD

- J2534 TECHNICAL SUPPORT - FREE for the life of the tool. Staffed by technicians who understand vehicle repair and J2534 Pass‑thru

- TOOLBOX WITH OEM APPLICATION DESCRIPTIONS - educational video tutorials and real-time news – Giving you the confidence and up-to-date knowledge to get the job done

- J2534 v05.00 API - The newest version of J2534 to give you the latest in pass-thru technology

- FUTURE PROOF WITH 4 CAN CHANNELS - Going beyond the 3 required by select Chrysler/FCA models, CarDAQ-Plus 3 also provides a 4th to meet the needs of future OEM applications

- CUSTOM-DESIGNED FOR USE WITH FORSCAN: Works with all FORScan compatible vehicles and is recommended by the FORScan Team

- DEALERSHIP-LEVEL DIAGNOSTICS: OBDLink EX supports all Ford

protocols, modules, and advanced features of FORScan

protocols, modules, and advanced features of FORScan - ELECTRONIC SWITCH allows FORScan to access all CAN buses simultaneously and enables advanced functions not possible with “toggle switch” adapters

- MAXIMUM THROUGHPUT -- up to 20 times faster than “toggle switch” adapters

- ROCK-SOLID CONNECTION avoids data corruption and dropped packets

- [J2534 COMPLIANT] - The Mastertech II is a J2534-1 and J2534-2 compliant VCI for OEM reprogramming and diagnostic applications

- [FULLY VALIDATED BY TOP 6 OEMS] - Mastertech II has been fully validated to operate with the top 6 OEM reprogramming applications: GM, Ford

, FCA, Nissan

, FCA, Nissan /Infinity, Honda/Acura, and Toyota

/Infinity, Honda/Acura, and Toyota /Lexus

/Lexus

- [PRE-CONFIGURED] - The pre-configured wireless and wired connections make it quick and easy to connect to a vehicle from your PC (requires PC compliant with OE specifications and software)

- [RIGHT TO REPAIR] - Supports 'Right to Repair' (R2R) initiatives

- [COMPREHENSIVE KIT] - Kit includes: VCI, WiFi adapters (wireless PC to VCI), J1962 Cable (connect to vehicle), USB cable (connect to PC for firmware updates and setup), and Quick Start Guide

Last update on 2025-05-08 / Affiliate links / Images from Amazon Product Advertising API

This product presentation was made with AAWP plugin.

, GM,

, GM,