| “This site contains affiliate links for which OEMDTC may be compensated” |

NHTSA ID Number: 10137938

Manufacturer Communication Number: PI0917F

Summary

This preliminary informational bulletin provides repair information to correct a customer concern of intermittent brake squeal or squeak noise on initial brake application.

8 Affected Products

Vehicles

Parts

SEOCONTENT-START

Bulletin No.: PI0917F

Date: Jul-2015

| Subject: | Brake Squeal or Squeak Noise Intermittently on Initial Brake Applies |

| Models: | 2013-2015 Cadillac ATS Equipped with RPO J55 ATS Equipped with RPO J55 |

2013-2015 Cadillac XTS Equipped with RPO J64 XTS Equipped with RPO J64 |

|

2014-2015 Cadillac CTS Sedan (VIN A) Equipped with RPO J55 or J56 CTS Sedan (VIN A) Equipped with RPO J55 or J56 |

|

| Attention: | This PI also applies to any of the above models that may be Export vehicles. |

This PI has been revised to remove the Regal GS and SS models, update the Parts and Warranty Information and the

procedure under Recommendation/Instructions. Please discard PI0917E.

Condition/Concern

Some customers may comment on a squeal or squeak noise from the front brakes. This condition normally only occurs on initial brake applications after the

vehicle has sat for an extended time. The condition occurs typically under light braking, in speeds under 16 km/h (10 mph). After 1-6 brake applies, or after

braking at higher speeds, the noise no longer occurs. This condition may occur more often in high humidity conditions.

Recommendation/Instructions

Important: Do not apply the copper paste to the back of the backing plate.

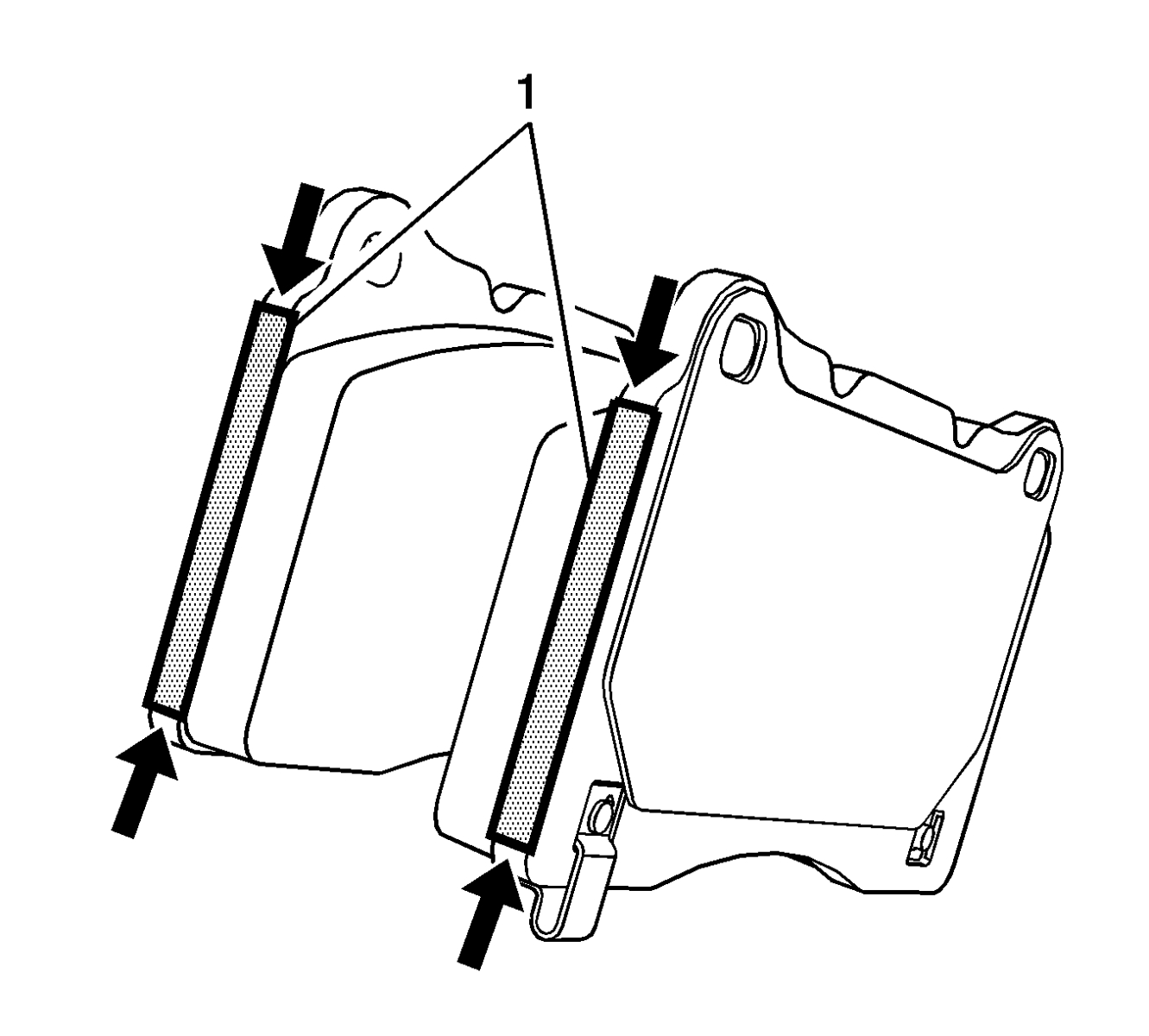

Replace the front brake pads and apply a coat of copper paste to completely cover the pad backing plate abutments on each end. The paste should not extend

onto the friction material. Follow the instructions listed below.

| (1) | Abutment Area |

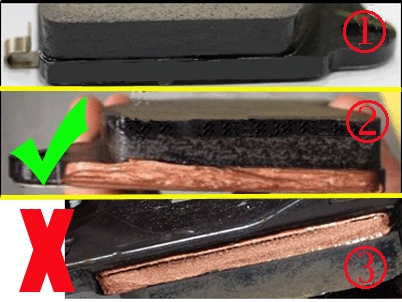

| (1) | Cleaned Abutment Area |

| (2) | Correct Amount of Copper Paste |

| (3) | Incorrect Amount of Copper Paste |

- Remove the front disc brake pads and discard.

- Wipe clean both ends of the abutment area of the calipers.

- Apply approximately 0.10 g (0.0035 oz) of copper paste to each end of the disc brake pad abutments that contact the brake caliper bracket.

Note: Avoid a light apply of the paste as illustrated above. - Install the front disc brake pads.

Parts Information

| Part Number | Description | Qty |

| 19303310 | Lubricant | 1 |

| 19303311 | Lubricant (In Canada) | 1 |

| 23271117 |

PAD KIT- FRT DISC BRK | 1 |

Warranty Information

For vehicles repaired under the Bumper-to-Bumper coverage (Canada Base Warranty coverage), use the following labor operation. Reference the Applicable

Warranties section of Investigate Vehicle History (IVH) for coverage information.

Labor Operation Description Labor Time

2420150 Front Disc Brake Pads Replacement Use Published Labor

Operation Time

SEOCONTENT-END

Bulletin No.: PI0917F

Date: Jul-2015

To View or Download this Document Click Here

Loading...

Loading...

Bulletin No.: PI0917D

Date: June, 2014

To View or Download this Document Click Here

Loading...

Loading...

Bulletin No.: PI0917D

Date: June, 2014

To View or Download this Document Click Here

Loading...

Loading...

Bulletin No.: PI0917C

Date: Feb-2014

To View or Download this Document Click Here

Loading...

Loading...

Bulletin No.: PI0917C

Date: February, 2014

To View or Download this Document Click Here

Loading...

Loading...

Bulletin No.: PI0917B

Date: Dec-2013

To View or Download this Document Click Here

Loading...

Loading...

Bulletin No.: PI0917B

Date: December, 2013

To View or Download this Document Click Here

Loading...

Loading...

Bulletin No.: PI0917A

Date: Apr-2013

To View or Download this Document Click Here

Loading...

Loading...

Bulletin No.: PI0917A

Date: April, 2013

To View or Download this Document Click Here

Loading...

Loading...

Bulletin No.: PI0917

Date: March, 2013

To View or Download this Document Click Here

Loading...

Loading...

| “This site contains affiliate links for which OEMDTC may be compensated” |

- A highly refined blend of aluminum, copper, and graphite lubricants that is salt, corrosion, and moisture resistant

- Use for easy assembly and disassembly of metal parts; enables easier disassembly of parts exposed to high temperatures

- Use during assembly to prevent galling, corrosion, and seizing due to weathering or chemicals

- Temperature Range: -80°F to 1600°F (-51°C to 871°C)

- Highly refined blend of aluminum, copper and graphite lubricants

- Salt, corrosion and moisture resistant, this lubricant is ideal for marine use

- Prevents galling, corrosion and seizing and to assure easier disassembly

- Suggested Applications: For easy removal of spark plugs, cylinder head and exhaust head bolts

- Temperature range: -60F to 1600F

- The information below is per-pack only

- Highly refined blend of aluminum, copper and graphite lubricants

- Salt, corrosion and moisture resistant, this lubricant is ideal for marine use

- Prevents galling, corrosion and seizing and to assure easier disassembly

- Suggested Applications: For easy removal of spark plugs, cylinder head and exhaust head bolts

- Prevents seizing, corrosion and galling where high temperature conditions exist

- Fortified with high quality rust and corrosion inhibitors

- Temperature range: -30F to 1800F

- Provides good electrical conductivity

- Suggested Applications: Spark plug threads installed in aluminum, exhaust manifold bolts, engine bolts, oxygen sensors, knock sensors, thermostat housing bolts, fuel filter fittings and battery cable connections

- Anti Seize:Prevents bonding and rusting on metal contact surfaces caused by high temperatures or prolonged operation, applied to the caliper braking system and caliper pins,brake pad,spark plug thread,bolts

- Rust and Corrosion Prevention: High-quality rust and corrosion inhibitors are added to protect metal parts from rust, corrosion, wear and tear and seizing in wet environments, ensuring easy disassembly and maintenance at a later stage

- Brake Quiet:Outstanding lubrication effect, stop squeak noise,improves the braking performance of the car and prolongs the service life of the parts

- Good Electrical Conductivity:Contains a high proportion of fine copper flakes with good electrical conductivity for battery cable connections,gate switch,Armature connectors

- Temperature Range: -30F to 1800F,ideal for use in spark plug threads, exhaust manifold bolts, brake hub bolts,engine bolts, thermostat housing bolts, fuel filter fittings,Injection moulding machine nozzles

- Prevents threaded fasteners from seizing and galling

- Protects metal parts in harsh conditions, high temperatures and extreme pressures

- For use where copper contamination must be avoided

- Effective on stainless steel, titanium and nickel alloys

- Convenient half-ounce tube is perfect for small scale jobs, including spark plugs, exhaust manifold bolts, muffler clamps, and tailpipe assemblies

- High Temp Copper Anti-seize Grease For Threaded Fittings Bolts & Nuts; Brush Top Applicator Included!

- Reduces Galling, Seizing, Welding & Carbon Fusion Providing A Dry-Film of Protective Solids On Threads; Reducing Total Amount of Torque Needed For Easier Disassembly

- Calcium Sulfonate Thickened Grease; Copper Fortified Grease Compound Unaffected By Severe Temperatures, Vibration, Expansion And Contraction

- Excellent Brake Lube Antiseize For Brake Pins and Brake Cam Assemblies Subject To Extreme Conditions: Water, Steam, Chemicals, Extreme Pressure, Rust & Corrosion

- Protects: Nuts, Bolts, Screws, Sprockets, Chains, Spark Plugs, Gaskets, Valve Assemblies, Splines, Gears & Conveyors

Last update on 2025-05-08 / Affiliate links / Images from Amazon Product Advertising API

This product presentation was made with AAWP plugin.