| “This site contains affiliate links for which OEMDTC may be compensated” |

NHTSA ID Number: 10154649

Manufacturer Communication Number: PI0564K

Summary

This preliminary informational bulletin provides frame coating repair information to correct a customer concern of wax coating on frame peeling, metal shows corrosion/rusting (U.S. and Canada Only).

111 Affected Products

Vehicles

CADILLAC | ESCALADE | 2011-2019 |

CADILLAC | ESCALADE ESV | 2011-2019 |

CADILLAC | ESCALADE EXT | 2011-2013 |

| CHEVROLET | AVALANCHE | 2011-2013 |

| CHEVROLET | EXPRESS | 2011-2019 |

| CHEVROLET | LOW CAB 4500 | 2017 |

| CHEVROLET | LOW CAB 5500 | 2017 |

| CHEVROLET | SILVERADO | 2017 |

| CHEVROLET | SILVERADO 1500 | 2011, 2014 |

| CHEVROLET | SILVERADO 2500 | 2011-2016, 2018-2019 |

| CHEVROLET | SILVERADO 3500 | 2013, 2017 |

| CHEVROLET | SILVERADO 4500HD | 2019 |

| CHEVROLET | SUBURBAN | 2011-2019 |

| CHEVROLET | TAHOE | 2011-2019 |

| GMC | SAVANA | 2011-2019 |

| GMC | SIERRA | 2017 |

| GMC | SIERRA 1500 | 2014, 2019 |

| GMC | SIERRA 2500 | 2011-2016, 2018-2019 |

| GMC | SIERRA DENALI | 2011-2013, 2015-2016, 2018 |

| GMC | YUKON | 2011-2019 |

| GMC | YUKON XL | 2011-2019 |

SEOCONTENT-START

Bulletin No.: PI0564K

Date: February, 2019

Service Bulletin

PRELIMINARY INFORMATION

| Subject: | Wax Coating on Frame Peeling, Metal Shows Corrosion/Rusting (U.S. and Canada Only) |

| Models: | 2011-2019 Cadillac Escalade Models Escalade Models |

| 2011-2013 Chevrolet Avalanche | |

| 2011-2019 Chevrolet Express, Silverado, Suburban, Tahoe | |

| 2019 Chevrolet Express, Silverado LD, Silverado 2500/3500, Suburban, Tahoe | |

| 2011-2018 GMC Savana, Sierra Models, Yukon Models | |

| 2019 GMC Savana, Sierra Limited, Sierra 2500/3500, Yukon Models |

This Bulletin also applies to any of the models that may be Export from North America vehicles. This PI has been revised to add the 2019 Model Year. Please discard PI0564J.

Condition/Concern

Some customers may comment that areas of the frame wax coating are peeling off and rust/corrosion is visible on the metal in these areas. Several examples of this condition are shown in each group of graphics below.

Truck Example Photos

Van Example Photos

Recommendation/Instructions

A combination of specialized metal coating products manufactured by Lloyds and Daubert have been found to be the most suitable products to provide corrosion control and protection to address this type of repair. Our recommendation is to prep the metal surface using *Lloyd’s Pure Prep™ Metal Surface Preparation P/N 25418, then topcoat with both *Lloyds Kryptonite Metal Treatment P/N 36502 Life Long Rust Protection and *Daubert Non-Rust® P/N X-121B One Coat Rust Preventative Coating. It is strongly recommended they be applied according to the manufacturer’s procedures.

*We believe this source and their products to be reliable. There may be additional manufacturers of such products/ materials. General Motors does not endorse, indicate any preference for, or assume any responsibility for the products or material from this firm or for any such items that may be available from other sources.

does not endorse, indicate any preference for, or assume any responsibility for the products or material from this firm or for any such items that may be available from other sources.

Important: To ensure proper coating performance, all of the manufacturer’s “Applications Guidelines” MUST be followed.

Prep the frame and apply the Lloyds and Daubert coatings following the steps below:

Important: The pictures below show the bed and/or cab removed from the vehicle. These pictures are provided for reference only. Bed and/or Cab removal are not necessary. Dealers should only repair the locations that show the condition. The following procedure should be utilized to return the truck to a factory look.

- Raise and suitably support the vehicle. Refer to Lifting and Jacking the Vehicle in SI.

- If labels are in the area to be reworked, remove any of the visible white labels on the frame (usually one per side).

- Remove any components as required to gain access to the corroded component or area.

Important: Any corrosion damage noted to the extent of weakening the component will require component replacement.

- Determine a start and finish point on each side for the section/area of the frame to be repaired.

- Using a rag and wax/grease removing solvent, remove the wax coating and any grease, oil, or undercoating from the truck frame in the affected repair area. The graphic above shows an example of a small portion of the wax coating removed.

Important: Lloyds Kryptonite is designed to apply directly onto brown rust or clean surfaces; however any loose flakes/scale of rust need to be removed prior to application.

- Any loose rust or loose flakes should be scraped, wire brushed or ground off.

- Remove any residual wax, oil or rust by wiping the frame down with a towel or Scotch-Brite™ (3M) pad soaked with wax/grease remover.

- Using Lloyd’s Pure Prep™ Metal Surface Preparation P/N 25418 (10 fluid ounce bottle), or equivalent, saturate a towel or Scotch-Brite™ (3M) pad with the pre-diluted solution and scrub the area well, rendering a foaming of the Pure Prep.™ This will greatly improve adhesion and corrosion resistance in the repair areas.

Important: The frame must be dry and free of wax/oily substances prior to application of the new coating.

- Using a water dampened clean towel, remove any residue and dry the affected area. Dry the repair area completely using an air hose to blow dry the frame.

- Check the repair area for phosphate treatment by wiping it to see if any corrosion residue can be picked up. Correctly treated areas will not have any residue on the surface.

- Apply a light flash-coat of Lloyds Kryptonite Metal Treatment P/N 36502 Life Long Rust Protection (14 ounce aerosol), or equivalent, to all rusted and bare areas of the frame where the wax coating was removed. This first coat should flash in approximately 3-5 minutes.

- Apply a second coat of Lloyds Kryptonite. This can be a heavy coat; double and triple passes with this product, over a light first coat, are not a problem.

Note: Dried Lloyds Kryptonite will perform beautifully over time and actually get harder and more durable as it experiences heat.

- We suggest top coating the Lloyds Kryptonite with Daubert Nox-Rust® P/N X-121B “One Coat Rust Preventative Coating” (aerosol), or equivalent.

Note: As shown in the graphic below, besides adding a corrosion resistant layer, it dries to firm, wax-like film which will more closely resemble the appearance of the unrepaired areas of the frame.

- Lower the vehicle and allow the final coat to dry as recommended by the manufacturer.

Parts Information

Dealers should obtain 25418 and 36502 by contacting Lloyds by e-mail at sales@lloydslaboratories.com, or by calling 1-800-361-6766.

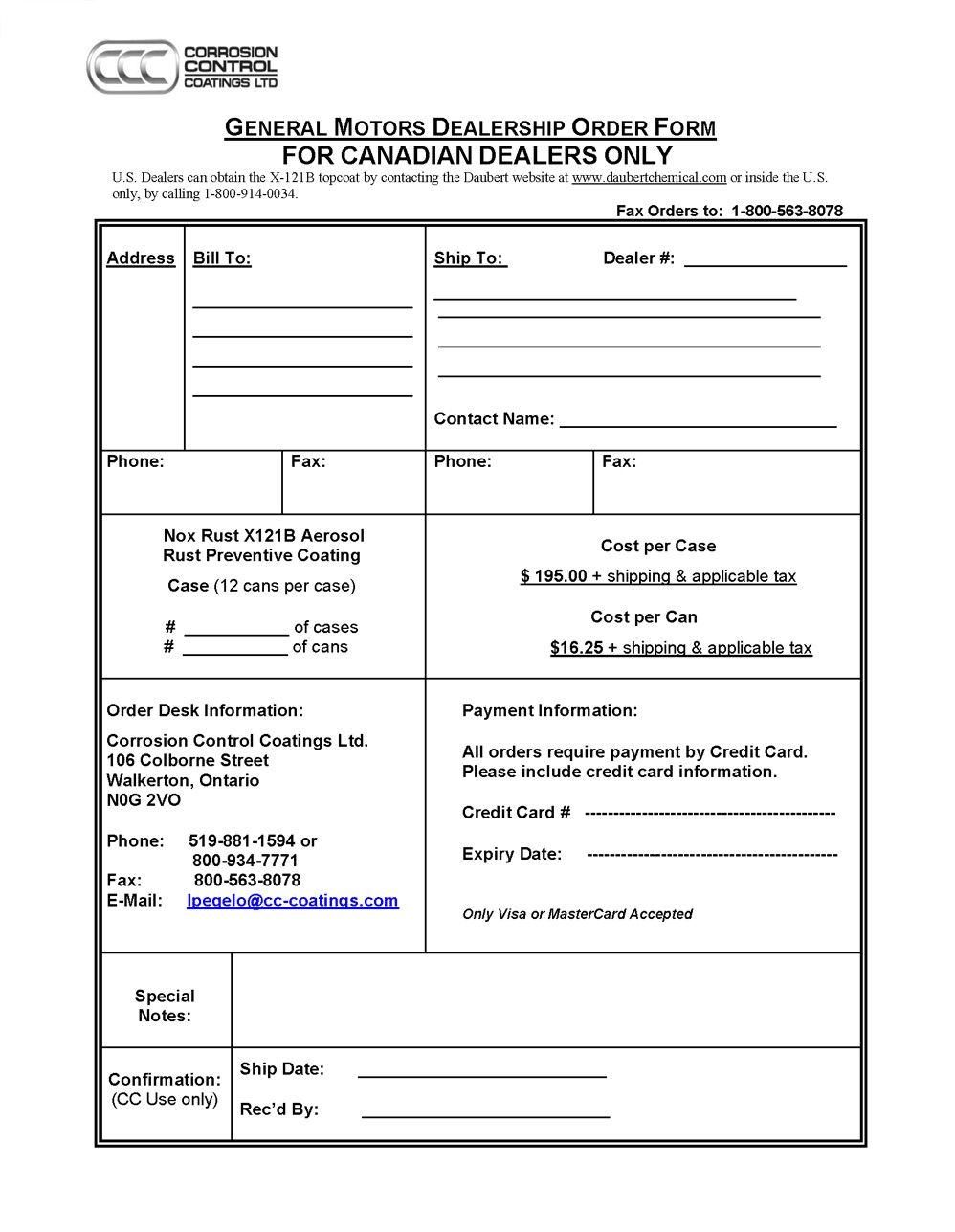

U.S. Dealers can obtain the X-121B topcoat by contacting the Daubert website at www.daubertchemical.com or inside the U.S. only, by calling 1-800-914-0034.

Canadian dealers must contact the Daubert distributor in Canada, Corrosion Control Coatings Ltd, by faxing the form below to 1-800-563-8078.

Important: ONLY Canadian Dealers should use this form.

Warranty Information

For vehicles repaired under warranty, use Labor Operation below and include material cost.

| Labor Operation | Description | Labor Time |

| 1480098* | Remove Frame Wax, Apply Metal Coating | Up to 7.0 hrs |

| *This is a unique Labor Operation for Bulletin use only. | ||

SEOCONTENT-END

Bulletin No.: PI0564K

Date: February, 2019

To View or Download this Document Click Here

Loading...

Loading...

| “This site contains affiliate links for which OEMDTC may be compensated” |

- Perfect for use on bare or primed metal underbodies of cars, trucks, trailers, RVs and more

- Rubberized formula protects against corrosion and damage from water, salt and other chemicals

- Dries to the touch in 30 minutes and covers up to 10-12 sq. ft. per can

- Undercoating helps deaden sound and reduce damage to parts

- Features a wide, comfort spray tip and any-angle spray technology for easy painting even upside down

- Perfect for use on bare or primed metal underbodies of cars, trucks, trailers, RVs and more

- Professional-grade formula provides superior protection against corrosion and damage from water, salt and other chemicals

- Dries to the touch in 1 hour and covers up to 10-15 sq. ft. per can

- Undercoating helps deaden sound and reduce damage to parts

- Features a wide, comfort spray tip and any-angle spray technology for easy painting even upside down

- Easy to use spray seals and protects metal surfaces from corrosion and moisture

- Flexible, rubberized coating provides superior chemical and abrasion resistance

- Dries to touch in 1-2 hours and covers 85-175 sq. ft. per qt. with rust protection

- Apply by brush, roller or spray to repair rust problems and prevent future issues

- Creates a protective coating with no shine, flat finish on rusted or bare metal

- MULTI-PURPOSE UNDERCOATING may be applied to cars, truck and recreational vehicles

- SOUND DEADENING PROPERTIES help reduce road noise

- ASPHALT-BASED product is excellent for wheel wells, quarter panels, interior fenders, under the hood and more

- PROTECTS THE UNDERCARRIAGE of vehicles from rust and abrasion

- AEROSOL DISPENSER allows for easy spray-on application

- FRAME COATING: This special aerosol spray is both a rust prevention and rust destroyer formula rolled into one. It will not only protect your chassis from the start of rust formation and allow you to maintain a clean finish, it also eliminates the need for any future maintenance or repairs, ensuring that it will be as good as new for years to come.

- HOW TO USE: Shake the can vigorously for at least 1 minute before and occasionally during use. Insert extension tube into spray nozzle then insert extension nozzle into frame openings, bolt holes, etc.Depress spray button and apply coating while pulling the extension nozzle back from the opening. Continue in all areas you can for complete coverage.

- EASTWOOD QUALITY: Eastwood offers solutions which combines our 4,000+ unique products with the know-how to “Do The Job Right”. With an In-house product design, development and testing and a strong track record of high-quality, innovative products. Used and trusted by top builders to beginners and also provides a Lifetime Tech Support.

- SAFETY INFORMATION: Always wear eye, skin and respiratory protection when applying this product.Use in a well ventilated area away from open flame. Store spray in a cool dry place. Warning: This product contains chemicals known to the State of California to cause cancer, birth defects or other reproductive harm.

- WARRANTY: Comes with a 90-day limited warranty and 90-day return. Can not be sold in the state of California.

- Paintable & Top Coat Compatible: Easily paintable, compatible with most top coats for a seamless, customized finish.

- Ready-to-Spray & Fast Drying: Convenient, ready-to-spray formula dries quickly, saving time on application.

- 50-State VOC Compliant: Meets all 50-state VOC regulations, ensuring environmental compliance.

- Convenient 4-Pack Kit with Spray Applicator Gun: Ideal for multiple projects, including truck undercoating spray applications.

- FLUID FILM BLACK offer powerful corrosion protection for all metals and superior lubrication for moving parts. The long lasting thixotropic liquids and gels is aptly used in the highly corrosive marine environment and vehicle undercoating in the automotive and snow handling industries

- HOW IT WORKS. The wet barrier creeps and migrates into tight seams and into the metal chassis to provide corrosion protection from salts and brines. Protects your vehicle while restoring a rich black color to the chassis or cover existing rust

- NO SOLVENT. Formulated from specially processed wool-wax, highly refined petroleum oils and selected agents, providing a non-toxic, non-irritating, non-flammable coating for corrosion control, penetration, metal wetting and water displacement

- WIDELY USED for maintenance of locks & hinges at home, lawn & garden tools & equipment, as well as in the aviation and automobile industries. In government and commercial facilities. Equipment in fishing, gas companies, farming, salt, power and industrial plants

- Comprehensive Protection: Provides a durable, rubberized coating that safeguards vehicle undercarriages from corrosion caused by moisture, salt, and other environmental factors.

- Sound Dampening: Effectively reduces road noise by dampening vibrations, contributing to a quieter ride.

- Easy Application: The aerosol spray format ensures a uniform application without running, suitable for cars, trucks, and recreational vehicles.

- Professional Grade: Trusted by professionals for its high-quality formulation, delivering reliable performance in various conditions.

- Pack of 6: Includes six 16 oz cans, providing ample coverage for multiple vehicles or extensive projects.

- FRAME COATING: This special aerosol spray is both a rust prevention and rust destroyer formula rolled into one. It will not only protect your chassis from the start of rust formation and allow you to maintain a clean finish.

- HOW TO USE: Shake the can vigorously for at least 1 minute before and occasionally during use. Insert extension tube into spray nozzle then insert extension nozzle into frame openings, bolt holes, etc.Depress spray button and apply coating.

- EASTWOOD QUALITY: Eastwood offers solutions which combines our 4,000+ unique products with the know-how to “Do The Job Right”. With an In-house product design, development and testing and a strong track record of high-quality, innovative products.

- SAFETY INFORMATION: Always wear eye, skin and respiratory protection when applying this product. Use in well ventilated area. Warning: Product contains chemicals known to the State of California to cause cancer, birth defects or other reproductive harm.

- WARRANTY: Comes with a 90-day limited warranty and 90-day return.

Last update on 2025-05-08 / Affiliate links / Images from Amazon Product Advertising API

This product presentation was made with AAWP plugin.