| “This site contains affiliate links for which OEMDTC may be compensated” |

NHTSA ID Number: 10058723

Manufacturer Communication Number: SC-14710

Summary

GMC/CHEVROLET: TSB CONTAINS AN OWNER’S NOTIFICATION LETTER. SELECT DOCUMENT SEARCH BUTTON BELOW. ON SOME TRUCKS, MESSAGE WILL DISPLAY SERVICE AIR BAG, DUE TO HIGH RESISTANCE OF SIDE IMPACT AIRBAG (SIAB) CIRCUIT CAUSING ILLUMINATION OF AIRBAG READINESS LIGHT. MODEL 2010-11 EQUINOX, TERRAIN.

4 Affected Products

Vehicles

Parts

| CLIP, WRG HARN SPLICE (Merch Pack of 10) | 4 | 05297428 |

| TUBING, SHRINK (1/8″ BLACK) (Merch Pack of 10) | 1 | 12355010 |

| WOVEN POLYESTER ELECTRICAL TAPE (PET) – PART NUMBER 1089482 – Obtain from Kent Automotive* | As Req’d | 1089482 |

| **LUBRICANT,DIELECTRIC (2 OZ) – US | As Req’d

| 12377900 |

| **LUBRICANT,DIELECTRIC (2 OZ) – CN | 10953529 |

SEOCONTENT-START

#14710: Special Coverage Adjustment – Illumination of Airbag Readiness Light/Service Airbag Message – (Jun 26, 2015)

| Subject: | 14710 – Special Coverage Adjustment – Illumination of Airbag Readiness Light/Service Airbag Message |

| Models: | 2010-2011 Chevrolet Equinox |

| 2010-2011 GMC Terrain |

Condition

On some 2010-2011 model year Chevrolet Equinox and GMC Terrain vehicles, high resistance in the side-impact airbag (SIAB) circuit may cause the airbag-readiness light to illuminate and the “SERVICE AIR BAG” message to display.

Special Coverage Adjustment

This special coverage covers the condition described above for a period of 10 years or 120,000 miles (193,000 km), whichever occurs first, from the date the vehicle was originally placed in service, regardless of ownership.

Dealers are to crimp and solder the SIAB wiring harness connector, located between the seat cushion and seat back, on the driver and passenger seats. The repairs will be made at no charge to the customer.

For vehicles covered by Vehicle Service Contracts, all eligible claims with repair orders on or after June 25, 2015, are covered by this special coverage and must be submitted using the labor operation codes provided with this bulletin. Claims with repair orders prior to June 25, 2015, must be submitted to the Service Contract provider.

Vehicles Involved

All involved vehicles are identified by Vehicle Identification Number on the Applicable Warranties section in GM Global Warranty Management system. Dealership service personnel should always check this site to confirm vehicle involvement prior to beginning any required inspections and/or repairs. It is important to routinely use this tool to verify eligibility because not all similar vehicles may be involved regardless of description or option content.

Parts Information

Parts required to complete this special coverage are to be obtained from General Motors Customer Care and Aftersales (GMCCA).

Customer Care and Aftersales (GMCCA).

| Part Number | Description | Quantity/ Vehicle |

| 05297428 |

CLIP, WRG HARN SPLICE (Merch Pack of 10) | 4 |

| 12355010 |

TUBING, SHRINK (1/8″ BLACK) (Merch Pack of 10) | 1 |

| 1089482 | WOVEN POLYESTER ELECTRICAL TAPE (PET) – PART NUMBER 1089482 – Obtain from Kent Automotive* | As Req’d

(Submit as Net Item) |

| 12377900 |

**LUBRICANT,DIELECTRIC (2 OZ) – US | As Req’d

(Submit as Net Item)

|

| 10953529 | **LUBRICANT,DIELECTRIC (2 OZ) – CN |

* To obtain the PET, contact Kent Automotive at 1-888-YES-KENT (1-888-937-5368) and request the special order part number 1089482.

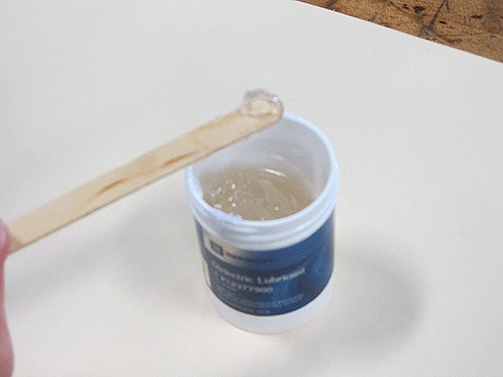

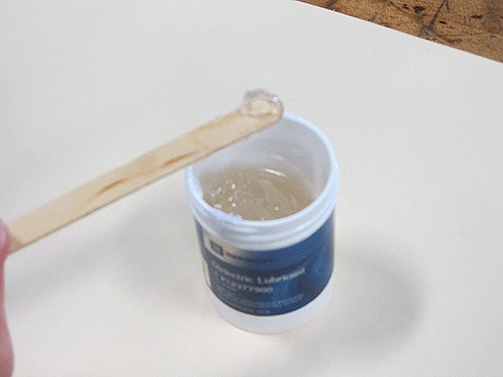

** This GM Dielectric Lubricant is required for this application. NO substitute is acceptable.

Service Procedure

Warning: When performing service on or near the SIR components or the SIR wiring, the SIR system must be disabled. Failure to observe the correct procedure could cause deployment of the SIR components. Serious injury can occur. Failure to observe the correct procedure could also result in unnecessary SIR system repairs.

Caution: Use only the dielectric lubricant listed in the part table above. Use of any substitute material may lead to a future failure of this repair.

- Disable the Supplemental Inflatable Restraints (SIR) system. Refer to SIR Disabling and Enabling in SI.

Note: Perform the procedure in this bulletin on BOTH the front driver and passenger seat. The SIAB connectors are located under the seat cushion.

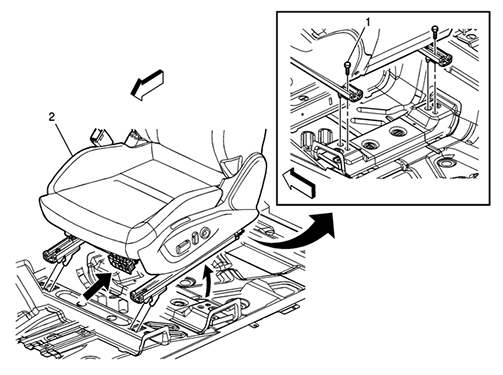

- Remove the passenger front seat. Refer to Driver or Passenger Seat Removal and Installation in SI.

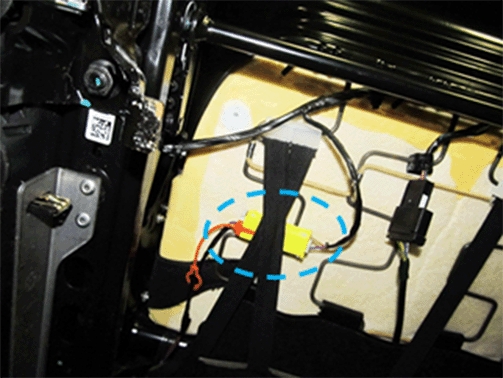

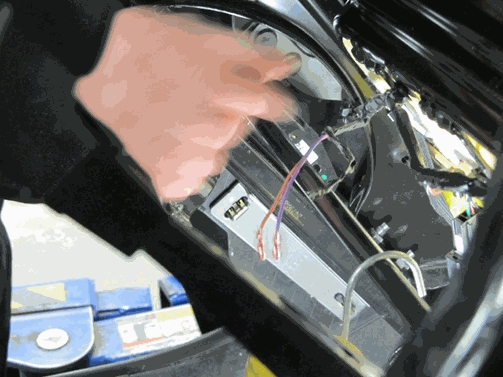

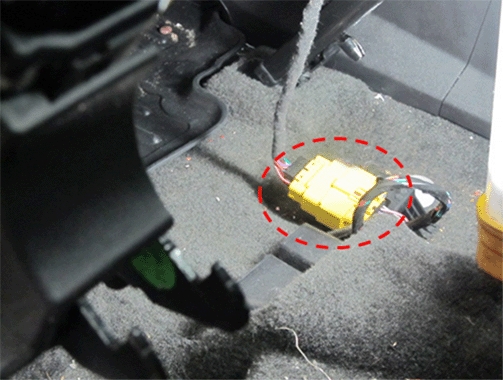

- Carefully remove the passenger front seat from the vehicle and place on a clean, covered work surface. Position the seat so you can access the yellow Side Impact Airbag (SIAB) harness connector (circled above) on the underside of the seat cushion.

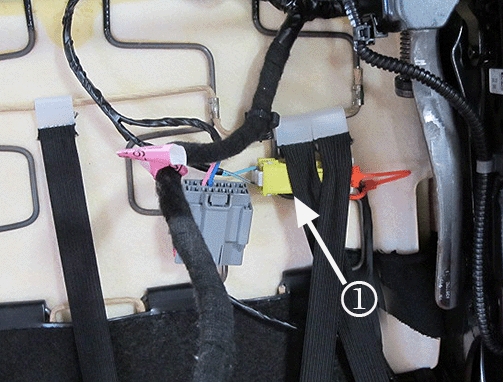

- Release the SIAB connector from under the seat cushion straps.

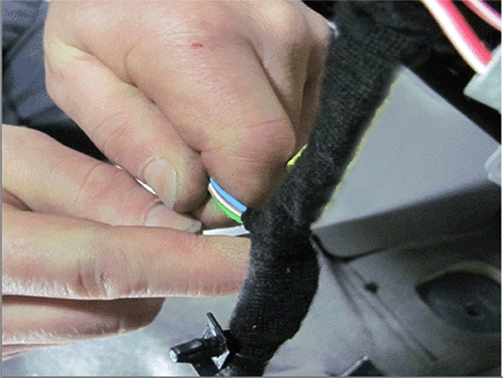

- Carefully remove approximately 76 mm (3 in) of conduit and tape from each side of the connector to gain access to the wires.

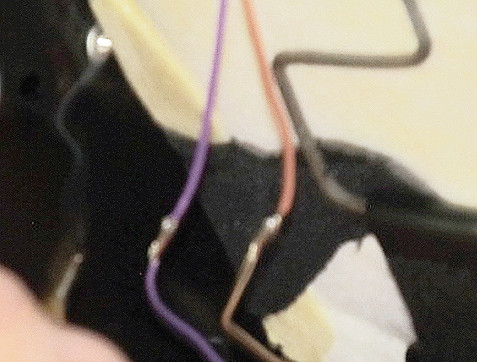

Note: Before removing the yellow connector from the harness, note the wire colors. Some wire pairs are very similar in color. Some wire pairs may have different colors. Ensure the wires are matched BEFORE splicing the wires of the harness together.

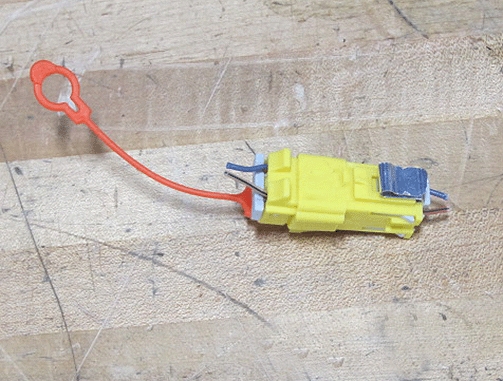

- As shown on the connector above, cut the wires from the harness connector as close to the connector housing as possible to minimize wire length loss.

- Strip off approximately 13 mm (1/2 in) of insulation from the four wiring ends.

Note: Only use heat shrink tube, P/N 12355010, or an equivalent flexible adhesive- lined/moisture resistant heat shrink tube to perform the repair in this bulletin.

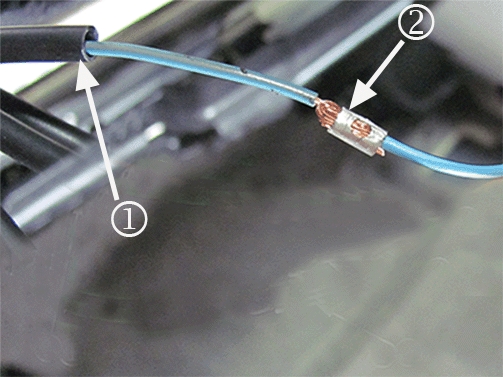

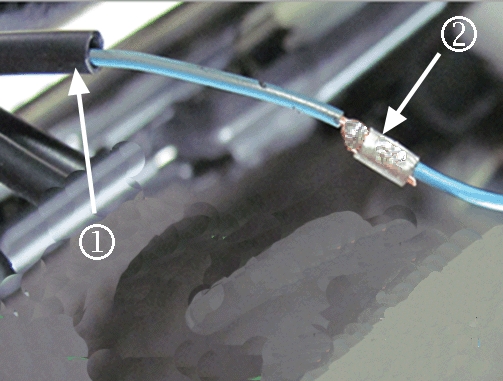

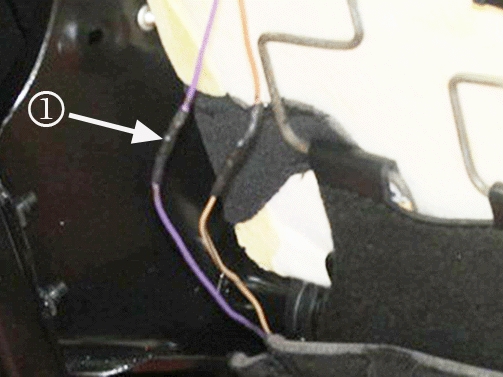

- Add one approximate 38 mm (1.5 in) section of heat shrink tube (1) to each wire on one side of the harness.

- Matching the appropriate color wire pairs, fold the 13 mm (1/2 in) ends of exposed copper wires over each other and crimp the splice clip (2) over the wires using Special Tool J-38125-8, crimp nest F.

- Verify the crimp quality.

- Fold the 13 mm (1/2 in) ends of exposed copper wires over each other and crimp the splice clip over the second set of wires.

Caution: Keep the heat shrink tube (1) above the splice (2) when soldering the splice to ensure that the heat shrink is not prematurely shrunk and closed down over the wire or splice area due to the heat from the soldering iron.

Warning: DO NOT use soldering equipment that is battery or electric powered. These types of soldering irons can induce voltage into the circuit, which may cause inflator module deployment and/or damage to electrical components. Use only the J-38125-5A Ultra Torch or another butane fueled soldering iron when working on SIR circuits.

- Solder both crimp and splice clips using the Ultra Torch, part number J-38125-5A, or another butane fueled soldering iron.

- Center the heat shrink tube (1) over both splices and shrink/seal the heat shrink tube securely over the splice crimp and insulated wires.

- Wrap woven polyester electrical tape (PET) or equivalent anti-abrasion tape or electrical tape (1) around the spliced section of both wires.

Caution: Avoid routing the harness along sharp metal edges. Ensure that harness is secured with some slack in the harness to allow the harness to flex or move.

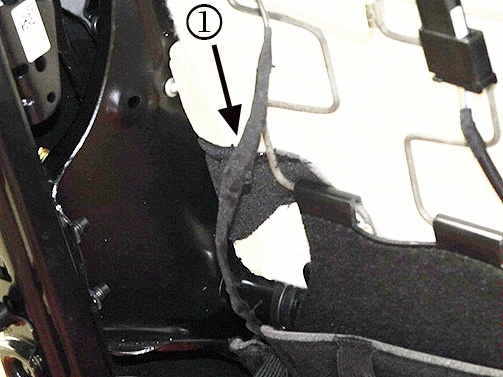

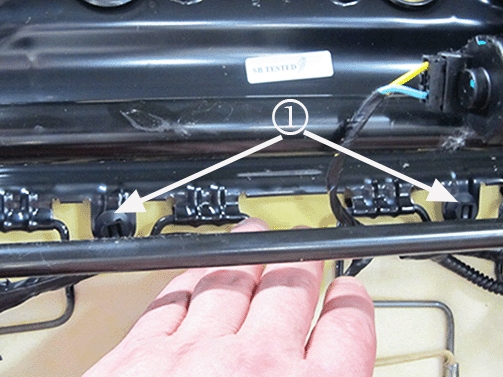

- Secure the harness in position underneath the cushion cover straps, as shown above.

- Before reinstalling the seat, apply dielectric lubricant (clear gel), GM P/N 12377900 (in Canada, use P/N 10953529), completely across the terminals on both sides of the seat and main body harness connectors.

- Reconnect the seat and body harness connectors. Wipe away any excess lubricant.

- Re-install the passenger seat. Refer to Driver or Passenger Seat Removal and Installation in SI.

- Carefully remove the driver front seat from the vehicle and place on a clean, covered work surface. Refer to Driver or Passenger Seat Removal and Installation in SI.

- Locate and release the SIAB connector (1) from under the seat cushion straps.

Note: Specific to the driver seat, more harness slack is necessary to allow soldering of the wire ends together. To allow more slack, the tie straps retaining the harness to the seat frame push-pins will need to be removed.

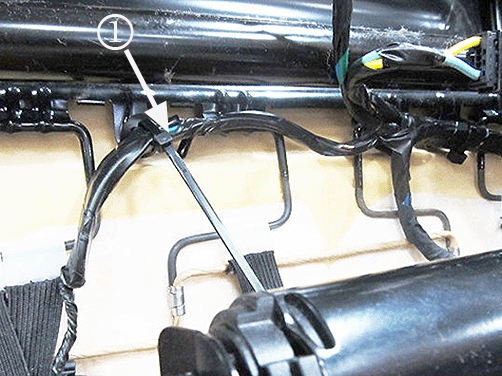

- At the underside, forward frame of the seat, cut and remove the two tie straps retaining the harness to the two push-pin retainers (1).

- Repeat steps 5 – 13 on the driver side seat.

Caution: Avoid routing the harness along sharp metal edges. Ensure that harness is secured with some slack in the harness to allow the harness to flex or move.

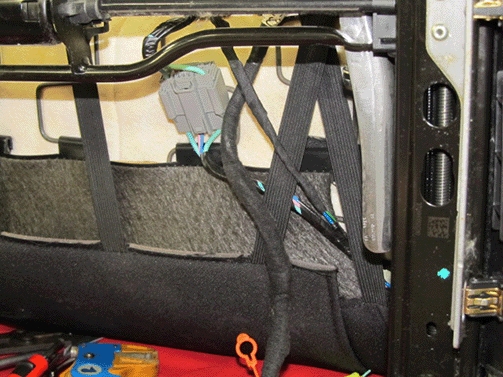

- Reroute the harness along the forward seat frame.

- Position the harness to the two push pins and install a new tie strap (1), procured locally, at each location.

- Snug the tie straps enough to retain the harness and trim off excess strap.

- Secure the harness in position underneath the cushion cover straps, as shown above.

- Before reinstalling the seat, apply dielectric lubricant (clear gel), GM P/N 12377900 (in Canada, use P/N 10953529), completely across the terminals on both sides of the seat and main body harness connectors.

- Re-install the driver seat. Refer to Driver or Passenger Seat Removal and Installation in SI.

- Enable the SIR system. Refer to Disabling and Enabling in SI.

- Clear any sensing and diagnostic module (SDM) DTCs using a scan tool. Verify that the airbag indicator is NOT displayed on the instrument panel cluster (IPC). If DTCs appear after clearing the SDM, refer to the appropriate diagnostic information in SI.

Customer Reimbursement – For US

Customer requests for reimbursement of previously paid repairs to correct the condition described in this bulletin are to be submitted to the dealer by July 31, 2016, unless otherwise specified by state law. If this is not convenient for the customer, the customer may mail the completed Customer Reimbursement Request Form and all required documents to the GM Customer Assistance Center. Repairs must have occurred within the 10 years of the date the vehicle was originally placed in service, or 120,000 miles, whichever occurs first.

All reasonable and customary costs to correct the condition described in this bulletin should be considered for reimbursement. Any questions or concerns should be reviewed with your GM representative prior to processing the request.

When a customer requests reimbursement, they must provide the following:

- A completed Customer Reimbursement Request Form. This form is mailed to the customer or can be obtained through GM GlobalConnect.

- The name and address of the person who paid for the repair.

- Paid receipt confirming the amount of the repair expense, a description of the repair, and the person or entity performing the repair.

Important: GM requires dealers to approve or deny a reimbursement request within 30 days of receipt. If a reimbursement request is approved, the dealer should immediately issue a check to the customer and submit an appropriate warranty transaction for the incurred expense. If a reimbursement request is denied, the dealer MUST provide the customer with a clear and concise explanation, in writing, as to why the request was denied. The bottom portion of the Customer Reimbursement Request Form may be used for this purpose. If the denial was due to missing documents, the customer can resubmit the request when the missing documents are obtained, as long as it is still within the allowed reimbursement period.

Warranty transactions for customer reimbursement of previously paid repairs are to be submitted as required by GM Global Warranty Management. Additional information can also be found in Warranty Administration Bulletin 11-00-89-004.

Customer Reimbursement – For Canada and Export

Customer requests for reimbursement of previously paid repairs to correct the condition described in this bulletin are to be submitted to the dealer prior to or by July 31, 2016. Repairs must have occurred within the 10 years of the date the vehicle was originally placed in service, or 193,000 kilometers, whichever occurs first.

When a customer requests reimbursement, they must provide the following:

- Proof of ownership at time of repair.

- Original paid receipt confirming the amount of unreimbursed repair expense(s) (including Service Contract deductibles), a description of the repair, and the person or entity performing the repair.

All reasonable and customary costs to correct the condition described in this bulletin should be considered for reimbursement. Any questions or concerns should be reviewed with your GM representative prior to processing the request.

Courtesy Transportation – For US and Canada

The General Motors Courtesy Transportation program is intended to minimize customer inconvenience when a vehicle requires a repair that is covered by the New Vehicle Limited Warranties. The availability of courtesy transportation to customers whose vehicles are within the warranty coverage period and involved in a product program is very important in maintaining customer satisfaction. Dealers are to ensure that these customers understand that shuttle service or some other form of courtesy transportation is available and will be provided at no charge. Dealers should refer to the General Motors

Courtesy Transportation program is intended to minimize customer inconvenience when a vehicle requires a repair that is covered by the New Vehicle Limited Warranties. The availability of courtesy transportation to customers whose vehicles are within the warranty coverage period and involved in a product program is very important in maintaining customer satisfaction. Dealers are to ensure that these customers understand that shuttle service or some other form of courtesy transportation is available and will be provided at no charge. Dealers should refer to the General Motors Service Policies and Procedures Manual for Courtesy Transportation guidelines.

Service Policies and Procedures Manual for Courtesy Transportation guidelines.

Warranty Transaction Information

Submit a transaction using the table below. All transactions should be submitted as a ZREG transaction type, unless noted otherwise.

| Vehicles Still Covered Under Applicable New Vehicle Limited Warranties | |||

| Labor Code | Description | Labor Time | Net Item |

| 2680268 | Driver and Passenger Seat SIAB Wire Repair | 1.6 | * |

Note: For reimbursements on vehicles covered under warranty, refer to the Policies and Procedures Manual.

| Vehicles No Longer Covered Under Applicable New Vehicle Limited Warranties | |||

| Labor Code | Description | Labor Time | Net Item |

| 9900192 | Driver and Passenger Seat SIAB Wire Repair | 1.6 | * |

| 9900193 | Customer Reimbursement Approved | 0.2 | ** |

| 9900194 | Customer Reimbursement Denied – For US dealers only | 0.1 | N/A |

Note: To avoid having to “H” route the customer reimbursement transaction for approval, it must be submitted prior to the repair transaction.

* The amount identified in “Net Item” should represent the actual sum total of the PET need to perform the required repair, and the current GMCCA Dealer net price for the dielectric lubricant needed to perform the required repairs, not to exceed $0.55 USD, $0.75 CAD, plus applicable Mark-Up or Landed Cost (for Export) for the dielectric lubricant.

** The amount identified in “Net Item” should represent the dollar amount reimbursed to the customer.

Customer Notification

General Motors will notify customers of this special coverage on their vehicles (see copy of typical customer letter included with this bulletin – actual divisional letter may vary slightly).

will notify customers of this special coverage on their vehicles (see copy of typical customer letter included with this bulletin – actual divisional letter may vary slightly).

July 2015

Dear General Motors Customer:

Customer:

This notice applies to your vehicle, VIN: __________________________________

As the owner of a 2010-2011 model year Chevrolet Equinox or GMC Terrain, your satisfaction with our product is very important to us.

This letter is intended to make you aware that, on certain 2010-2011 model year Chevrolet Equinox and GMC Terrain vehicles, high resistance in the side-impact airbag circuit may cause the airbag-readiness light to illuminate and the “SERVICE AIR BAG” message to display.

Do not take your vehicle to your GM dealer as a result of this letter unless you believe that your vehicle has the condition as described above.

What We Have Done: General Motors is providing owners with additional protection for the condition described above. If this condition occurs on your 2010-2011 model year Chevrolet Equinox or GMC Terrain within 10 years of the date your vehicle was originally placed in service or 120,000 miles (193,000 km), whichever occurs first, the condition will be repaired for you at no charge. Diagnosis or repair for conditions other than the condition described above is not covered under this special coverage program.

is providing owners with additional protection for the condition described above. If this condition occurs on your 2010-2011 model year Chevrolet Equinox or GMC Terrain within 10 years of the date your vehicle was originally placed in service or 120,000 miles (193,000 km), whichever occurs first, the condition will be repaired for you at no charge. Diagnosis or repair for conditions other than the condition described above is not covered under this special coverage program.

What You Should Do: If you believe that your vehicle has the condition described above, repairs and adjustments qualifying under this special coverage must be performed by a General Motors dealer. You may want to contact your GM dealer to find out how long they will need to have your vehicle so that you may schedule the appointment at a time that is convenient for you. This will also allow your dealer to order parts if they are not already in stock. Keep this letter with your other important glove box literature for future reference.

dealer. You may want to contact your GM dealer to find out how long they will need to have your vehicle so that you may schedule the appointment at a time that is convenient for you. This will also allow your dealer to order parts if they are not already in stock. Keep this letter with your other important glove box literature for future reference.

Reimbursement: If you have paid for repairs for the condition described in this letter, please complete the enclosed reimbursement form and present it to your dealer with all required documents. Working with your dealer will expedite your request, however, if this is not convenient, you may mail the completed reimbursement form and all required documents to Reimbursement Department, PO Box 33170, Detroit, MI 48232-5170. The completed form and required documents must be presented to your dealer or received by the Reimbursement Department by July 31, 2016, unless state law specifies a longer reimbursement period.

If you have any questions or need any assistance, just contact your dealer or the appropriate Customer Assistance Center at the number listed below.

| Division | Number | Text Telephones (TTY) |

| Chevrolet | 1-800-222-1020 | 1-800-833-2438 |

| GMC | 1-800-462-8782 | 1-888-889-2438 |

| Guam | 65-6267-1752 | |

| Puerto Rico – English | 1-800-496-9992 | |

| Puerto Rico – Español | 1-800-496-9993 | |

| Virgin Islands | 1-800-496-9994 |

We are sorry for any inconvenience you may experience; however, we have taken this action in the interest of your continued satisfaction with our products.

Alicia S. Boler-Davis

Sr. Vice President

Global Connected Customer Experience

Enclosure

14710

SEOCONTENT-END

Bulletin No.: 14710

Date: June 2015

To View or Download this Document Click Here

To View or Download this Document Click Here

- Time Saver: Solderless,crimpless, all you need is just a heat gun to finish the joint, much faster and easier than the old way

- Fit for Confined and Narrow Spaces: Can be bent after connection and no need to crimp or solder in the confined area, just control the temperature via a heat gun

- Waterproof and Seal Performance: There is two hot melt waterproof adhesive rings in each butt connector, which help it hold up better to moisture

- High Temperature Proof in A Short Time: Use exclusive material in the butt connectors to avoid shrink tubing melting before solder ring

- IATF16949:2016 Listed: The Kuject solder seal connectors meet the newest standard of International Automotive Task Force, which is the most standardized way for you to repair or modify your car

- 【PREMIUM IN QUALITY】- Every single piece of our crimp connectors is made with tinned thick red copper barrel and polyolefin heat shrink tubing[Shrink Ratio 3:1], which ensure secure crimping and tight wire connection with high current flow and minimum voltage drop, preventing wire failures

- 【SAFETY MATTERS】- Safety is the top priority during any of your work, certificated products can ensure you reassured and secure using experience. Our heat shrink connectors meet the standards of CE, RoHS, ISO9001, SGS, you’re allowed to use these proffesional butt splice connectors with full confidence for a variety of electrical projects and wire connection issues

- 【MADE TO LAST】- Thanks to the thick tinned copper and seamless barrel desgin, it ensures strong and secure crimping all the time with no wire coming off issues. What's more, the polyolefin heat shrink tubing provides the high tensile strength and resistance to mechanical damage so there's no worry of rat chewing or similiar phisical damage issues. When heated with a heat gun, the adhesive melting inside create a waterproof and insulated seal, preventing electric leakage and corrosion

- 【WIDE APPLICATION】- Marine grade heat shrink butt splices can be widely applied in areas such as automotive industry, marine, science projects, family electrical wire connections and so on, due to its durability, steadily, water and corrosion resistace

- 【COST EFFECTIVE PACKAGE】- Considerate product quantity of 100pcs/pack

- COMPLIANT WITH ALL RELEVANT STANDARDS:With Haisstronica 330PCS( A.W.G.:22-16 150 PCS,16-14 100 PCS,12-10 32 PCS,26-24 48 PCS) heat shrink waterproof wire connectors are compliant with ROHS, ISO 9001:2008, SGS, and CE standards

- HIGH-QUALITY COPPER CORE:Heat shrink butt connectors use a copper core with a higher thickness rating.This makes your connection project safer and better meets our customers’ quality needs

- HIGH-QUALITY HEAT SHRINK:Translucent heat shrink tubing provides high tensile strength and resistance to stretch and minimize mechanical damage.The thick barrel ensures a strong crimp every time.The inner wall of the heat-shrinkable tube has enough hot melt adhesive to ensure waterproof performance reliability.Your wire will never slip out of these heat shrink wire connectors

- RECOGNIZABLE:Tubings of varying colors with easily recognizable wire gauge markings. Simply measure the wiring, and by checking the mark of wire gauge of the polyolefin tubing, then you can quickly choose the right connector

- WIDE APPLICATIONS: High quality 3:1 shrinkage tubing has a heat-activated sealant lining to provide complete secure seal. It's flame-retardant, waterproof, and can be used underground. Compliant with all electrical standards, Perfect for marine and automobile applications, whether you are working on your boat, Vehicle, Home or scientific project

- ✔️【PREMIUM QUALITY】Thick copper barrel ensures strong secure crimping every time, providing minimal voltage drop, high current flow, and less heat. These will prevent short circuits and problematic wiring that inferior connectors are known for

- ✔️【DURABILITY】Each terminal features a thick tinned copper barrel that resists corrosion to hold the wire tight when crimped. The barrel is created from one seamless piece of copper that eliminates the problem of the barrel opening. Your wire will never slip out of the connector

- ✔️【WATERPROOF】Insulation tubing has unique dual-walled design. High quality 3:1 shrinkage tubing has a heat-activated sealant lining to provide a 360 degree secure seal. It's flame-retardant, waterproof, and can be used underground

- ✔️【WIDE APPLICATIONS】Compliant with all electrical standards, Perfect for marine and automobile applications, whether you are working on your boat, Vehicle, Home or scientific project, our electrical crimp connector will ensure strong watertight seal to make sure everything bond correctly. The connector assortment includes red (AWG 22 – 16), blue (AWG 16 – 14) and yellow (AWG 12 – 10) butt connectors that can be used on wire AWG from 22 to 10

- ✔️【TICONN BRAND QUALITY COMMITMENT】We stand behind the quality of our products. If for any reason you are not satisfied with your purchase, please contact us. We provide 30-day money back and 24-month warranty. 100% Satisfaction Guarantee for risk-free shopping!

- Multiple Choices: Proper ratio of various types to meet the commonly used types needs. This wiring terminals kit contains ring, fork, spade, and heat shrink butt connectors

- Stronghold and Durability: We adopt premium copper core to ensure good electrical conductivity and durability. Heat shrink crimp connectors provides greater pull strength

- Waterproof: With the adhesive melted when heated, the heat shrink tubing seals all the way to the end of the barrel. The connections were to be outside or inside the vehicles, will perform good water proof

- Straightforward Visual Inspection: Translucent, adhesive-lined polyolefin tubing for straightforward visual inspection, prevents wire corrosion, and provides a waterproof seal

- Wide Applications: Good electrical conductivity and water proof provide connection for your automotive, motorcycle, and marine application. Widely used on multiple projects of your vehicle or ATV lighting, motorcycle stereo, boat electronics, equipment switches

- [EXECELLENT QUALITY] : Direct factory with excellent quality control, STRONG & DURABLE. The copper core of our heat shrinkable joints is made of high quality tinned copper, in addition to being extremely conductive, it is easier to flatten and grip the wire

- [EASY USE] : Take two wires you wish to join. Remove the wire insulator, pick the terminal color you want. Insert the wire into the terminal one at the time and crimp by crimping tool, insert another terminal and crimp. Use air gun to apply heat on the heat shrink connectors.

- [PRACTICAL DESIGN] : Double-wall design, outer layer of polyolefin tube, inner layer of hot melt adhesive, precise crimping and good contact. Electrical butt connectors provide high tensile strength and adequate hot melt adhesive inside the tube. After shrinking, the wiring is firm and not loose, and it can ensure that the current continues to flow smoothly.

- [WIDE APPLICATIONS] : Our waterproof terminals are perfect for marine, automobile applications, electrical and electronics industries. Whether working on your Boat, Vehicle, Home, or Scientific project, the electrical crimp connector will ensure a strong waterproof seal to make sure everything bonds correctly.

- [PACKAGE INCLUDED] : 25 pcs red connector ( 22-16 AWG ), 15 pcs blue connector ( 16-14 AWG ), 10 pcs yellow connector ( 12-10 AWG ).

- 3:1 Heatshrink Ratio: The heat shrink butt connector has dual-wall shrinking tube and inside hot melt glue, providing a fully safe seal and wire corrosion. Its dual wall insulation seals against moisture corrosion, air leakage, and can be used underground

- Premium Copper Core: The butt splice terminals use seamless and high-quality thick copper tubular, which makes the connection project safer! Fix the wire firmly, increase current flow, and decrease voltage drop

- Wide Usage: Our heat shrink wire connector is ideal for marine, automobile, industry, electrical and electronics. Whether working on boat, vehicle, RC car, home, scientific project, car stereo, or electrical DIY, the crimp connectors will work well

- Package Included: 50 pcs red waterproof wiring connectors for 22, 20, 18, 16 gauge wires, 40 pcs blue waterproof wiring connectors for 16, 14 gauge wires, 10 pcs yellow waterproof wiring connectors for 12, 10 gauge wires—total 100 pcs

- AIRIC Brand Advantages: As a professional manufacturer of electrical accessories, we own a large leading wire connectors factory and get UL, CE, ROHS, SGS, and ISO9001-2005 international quality system certification

- Tinned Copper Core: Butt connectors use a heavy-duty copper core, strong crimp, higher conductivity

- Package Includes: 100Pcs Blue heat shrink butt connectors that can be used on wire AWG from 16 to 14

- Solderless Crimping: Insert the wires to be connected, crimp both sides with crimping pliers, and then heat with a heat gun

- 3:1 Shrink Ratio: Marine grade heat shrink tubing provides high tensile strength and enough hot melt adhesive inside the tubing to ensure waterproof performance, your wires will never slip out of the wire connectors

- Wide Application: Wire connectors are waterproof, stable, and corrosion resistant and are used in the automotive, marine, electrical, and electronic industries

- [EXECELLENT QUALITY] - Direct factory with excellent quality control, STRONG & DURABLE. The copper core of our heat shrinkable joints is made of high quality tinned copper, in addition to being extremely conductive, it is easier to flatten and grip the wire

- [WATERPROOF] - Waterproof insulated, the polyolefin tubing on the outside and the hot-melt glue inner layer provide excellent water resistance when heated. The polyolefin tube reduces in size and the adhesive flows within the insulation

- [PERFECT FOR] - Perfect use for the repair technician on the electrical wiring. Seamless copper barrel design provides high tensile strength and mechanical damage resistance, translucent heat shrink tubing eliminates the issue of the barrel opening, high elasticity keeps steady performance

- [EASY USE] - Take two wires you wish to join. Remove the wire insulator, pick the terminal color you want. Insert the wire into the terminal one at the time and crimp by crimping tool, insert another terminal and crimp. Use air gun to apply heat on the heat shrink connectors

- [PACKAGE INCLUDES] - 200pcs Heat Shrink Butt Connectors. 3 Sizes, 90pcs Red, 9Opcs Blue and 20pcs Yellow.

- PREMIUM COPPER CORE AND HEAT SHRINK TUBE: Made of high quality tinned copper and adhesive lined heat shrink tubing. These professoinal butt connectors ensure protection against the elements. Heat shrink tubing provides high tensile strength and resistance to stretch and mechanical damage, high thickness copper core ensure protection against the elements

- STRONG CRIMPS: These butt connectors use thick, seamless copper barrels. Your wire will not pull out of these butt splices when crimping

- EXCELLENT WIRE CONTACT: The copper barrel provides increased current flow, and ensures less voltage drop, preventing wiring failures and reducing equipment downtime

- RELIABLE CONNECTION: Adhesive lined inside the 3:1 butt heat shrink connector will exude hot melt adhesive when evenly heated, shrinks quickly and adheres to wire insulation. Guarantees good environmental sealing, waterproof and wear-resistant

- WIDE APPLICATIONS: Excellent stability, water resistance and electrical conductivity provide durable connection for motorcycle, off-road vehicles, lawn tractors,RVs,fish finder and marine application. Widely used on multiple projects of your Christmas lights,ships with high waterproof requirements motorcycle stereo, boat electronics, equipment switches

Last update on 2025-05-08 / Affiliate links / Images from Amazon Product Advertising API

This product presentation was made with AAWP plugin.

Dealer completed work, Airbag light illuminated half way home. Is there other work covered by this.

You will ave to check for codes to see why the light came on. Maybe something wasn’t plugged in all the way and came loose.

Our dealership said it wasn’t covered and would be $1100 to repair. Said passenger airbag is shorted internally.

The dealership I went to said hat to diagnosis it, it would be covered under the special warranty.

They usually do, there are many reasons why the Airbag light can be on.

my 2011 equinox has the ‘service airbag’ indicator illuminated. I took it to the dealer along with my letter that informed me of the needed repairs. that’s when I found out the underlying scam. first I have to agree to a $150 test which will confirm if the problem is the one that’s covered. If it is, then they’ll fix it at no cost. If not, I’m out $150. classic chicken and egg scenario…. if I never agree to the test, then you’ll never have to repair it. quite honestly, since this is a KNOWN PROBLEM, better customer service would be to perform a courtesy test.