| “This site contains affiliate links for which OEMDTC may be compensated” |

NHTSA ID Number: 10111752

Manufacturer Communication Number: 16-NA-265

Summary

This technical bulletin provides a procedure to replace the rear axle harness and module if corrosion has been found in the connectors.

2 Affected Products

Vehicle

CADILLAC | XTS | 2016-2017 |

Parts Information

| MODULE KIT, RR DIFF CLU CONT | 23183680 | 1 |

| HARNESS, SUSP ACTR WRG | 23459989 L

With COLL IMMINENT BRK-ALL SPEED, VEH FWD MOVEMENT, BRAKE PREFILL, INTEGRATED BRAKE ASSIST | 1 |

| 23459990 L | 1 |

SEOCONTENT-START

Bulletin No.: 16-NA-265

Date: Dec-2016

| Subject: | Dead Battery and/or Service Rear Axle Message Displayed |

| Brand: | Model: | Model Year: | VIN: | Engine: | Transmission: | ||

|---|---|---|---|---|---|---|---|

| from | to | from | to | ||||

Cadillac |

XTS | 2016 | 2017 | Automatic (M7U) | |||

| Involved Region or Country | North America, Middle East |

| Additional RPOs | UGN, F55, F46, G96 |

| Condition | Some customers may comment on the following conditions: |

| Cause |

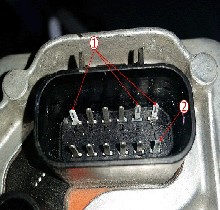

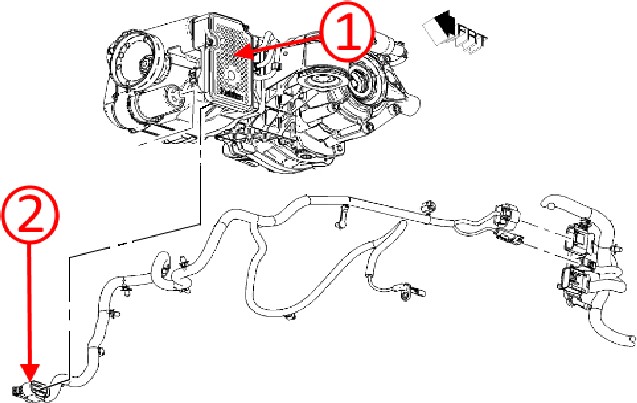

This may be caused by moisture entering the rear axle to suspension actuator wiring harness through an opening in the wiring insulator, causing corrosion (1, 2) in the K47 connector. |

Correction

Inspect the K47 connector for corrosion/moisture. If corrosion/moisture has been found in the connector for the rear axle to suspension actuator wiring harness (2) and the rear differential clutch control module (RDCCM) (1), both components must be replaced.

Removal

- Deflate the suspension air bags. Refer to Air Suspension System Depressurization and Pressurization in SI.

- Remove the RDCCM. Refer to Rear Differential Clutch Control Module Replacement in SI.

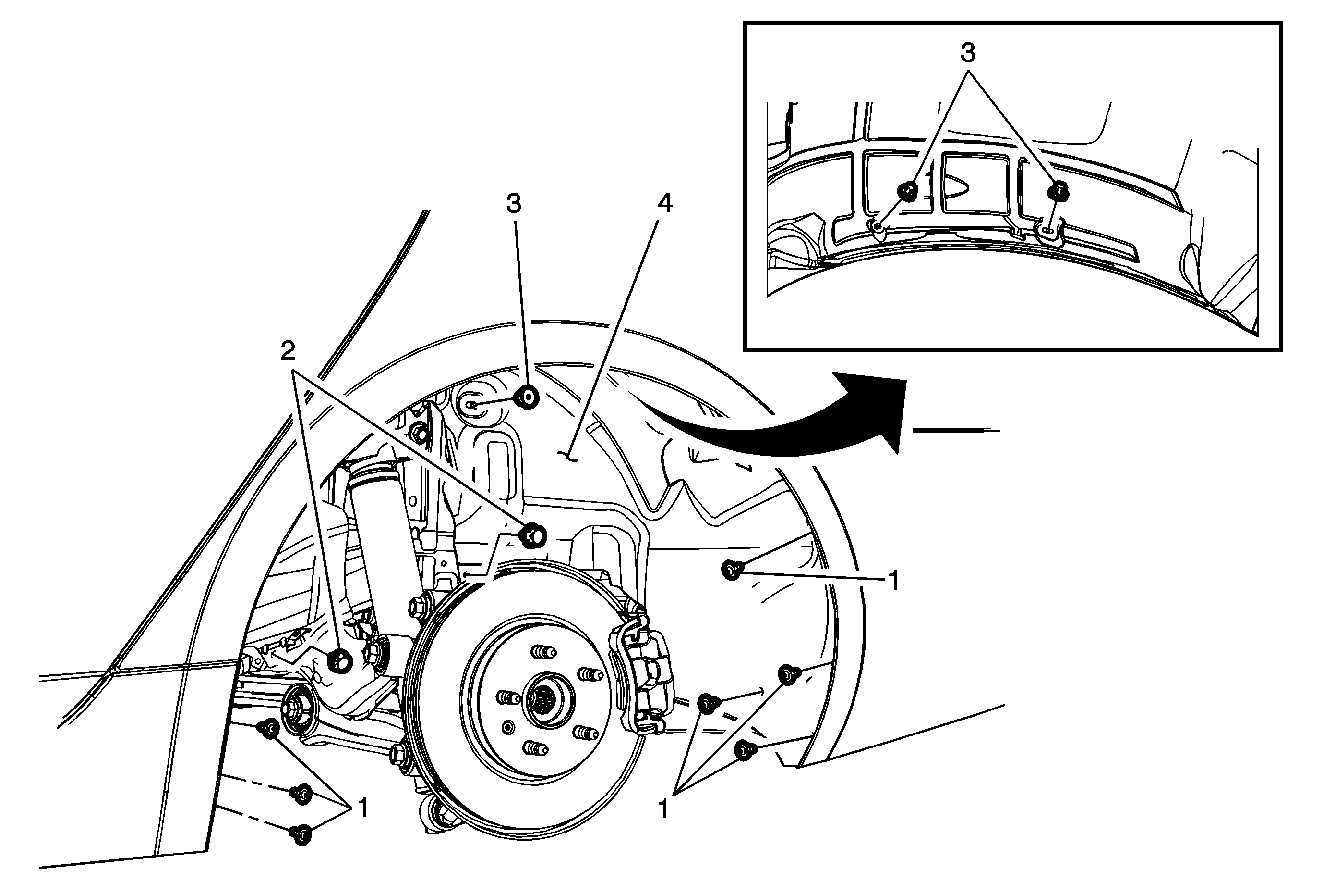

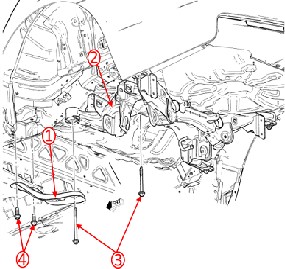

- Remove the rear wheelhouse liner (4).

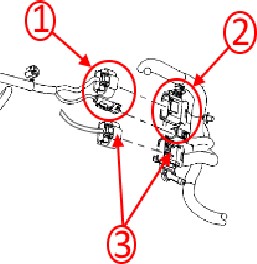

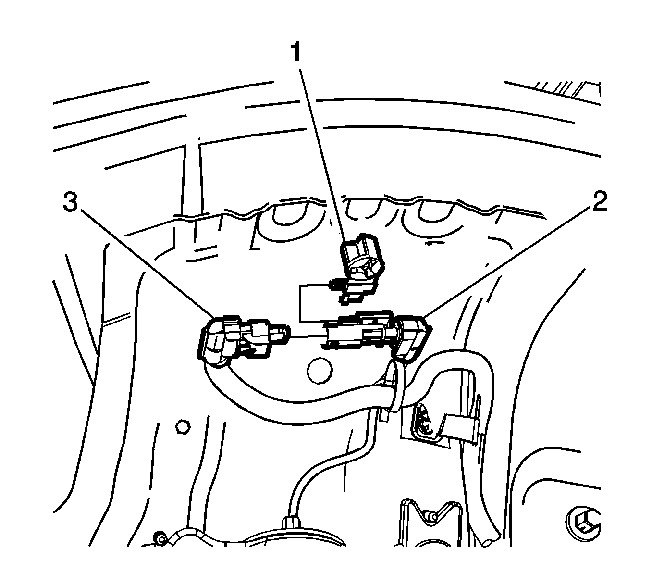

- Disconnect the ABS sensor and control module electrical connectors (1) from the body side wiring harness (2).

- If equipped with integrated braking assist, disconnect the electrical connector (3).

- Separate the wiring harness from the body.

- Disconnect the strut electrical connector (2) and separate the wiring harness from the body.

Caution: Support the brake caliper with heavy mechanic wire, or equivalent, whenever it is separated from its mount and the hydraulic flexible brake hose is still connected. Failure to support the caliper in this manner will cause the flexible brake hose to bear the weight of the caliper, which may cause damage to the brake hose and in turn may cause a brake fluid leak.

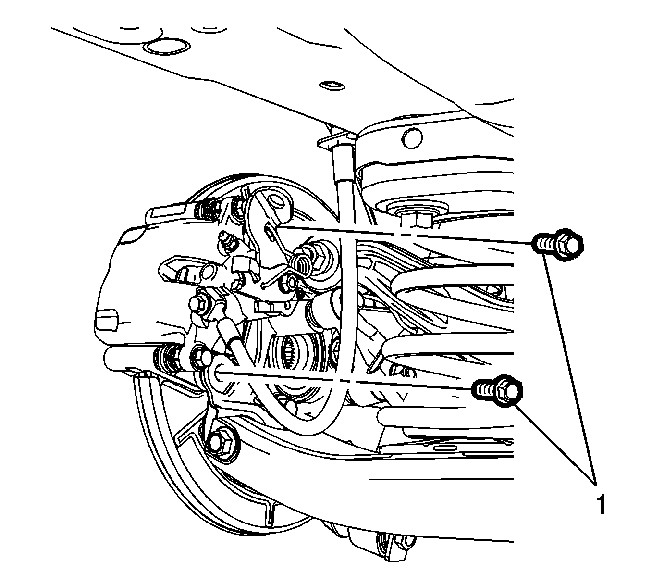

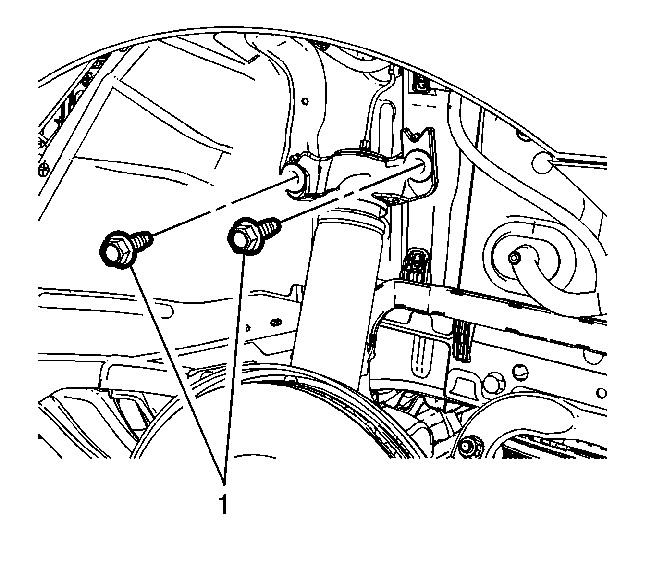

- Remove the bolts (1) that secure the brake caliper to the caliper bracket.

- Secure the brake caliper to the body using mechanics wire or equivalent.

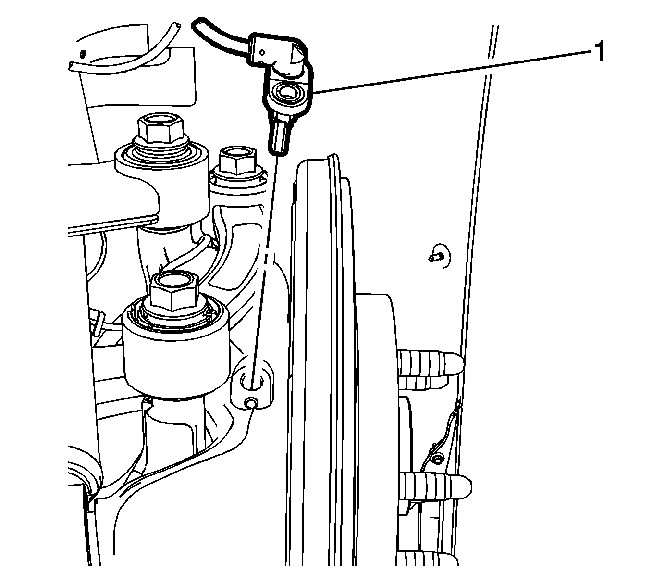

- Remove the ABS sensor (1).

- Separate the ABS wiring harness from the upper control arm.

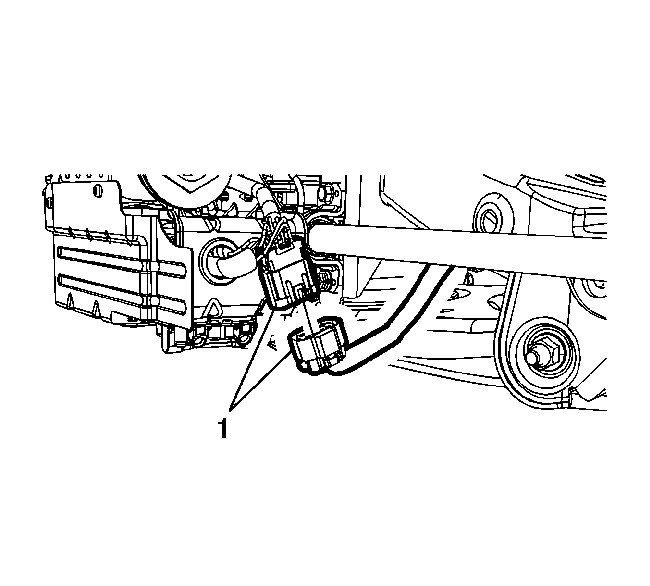

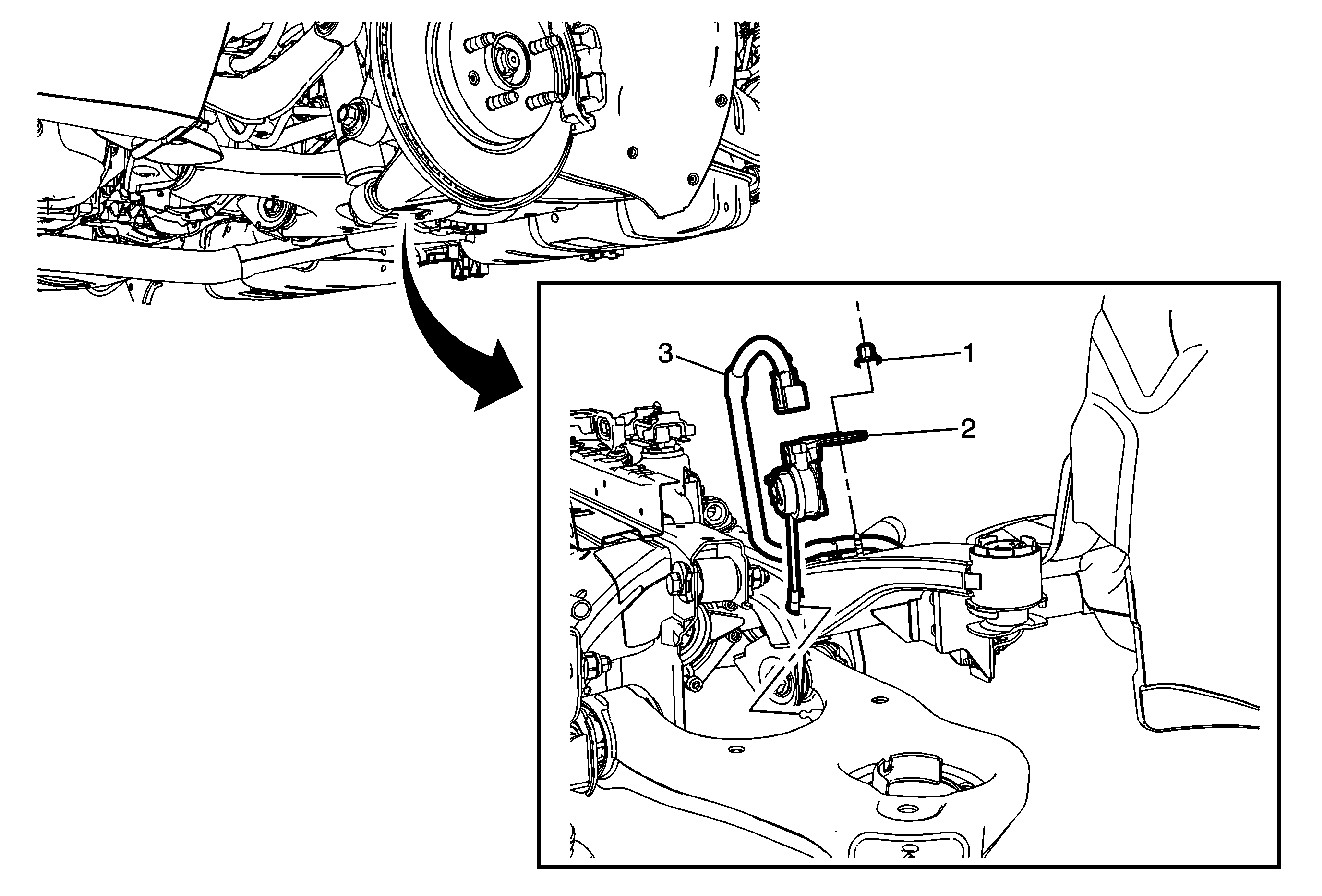

- Disconnect the air ride pump electrical connector (1).

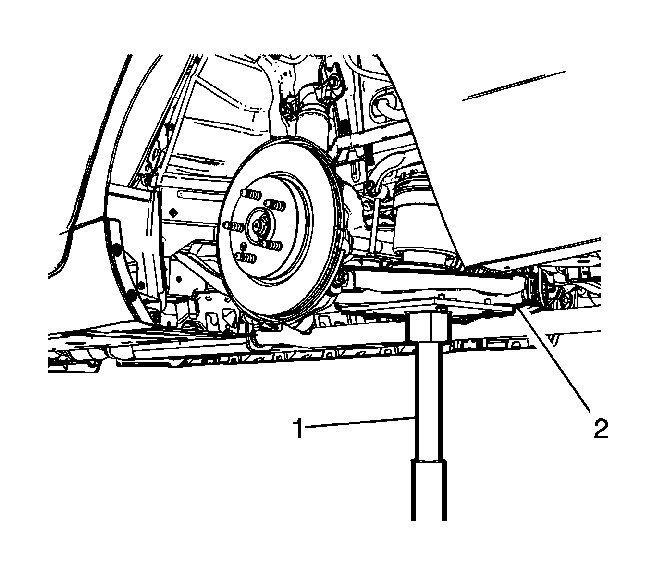

- Support the rear cradle assembly with a support stand (1) or equivalent.

- Remove the two left side cradle reinforcement bracket bolts (4).

- Remove the two left side cradle bolts (3).

- Remove the two upper strut bolts (1).

- Using care, lower the cradle assembly so that only the left side is lowered.

- Disconnect the ride height sensor electrical connector (3).

- Remove the wiring harness from the suspension cradle.

Installation

- Route and position the wiring harness through the suspension cradle.

- Connect the ride height sensor electrical connector.

- Install the wiring harness to the suspension assembly.

- Using care, raise the suspension cradle into position.

- Install the rear cradle bolt hand tight.

- Position the front cradle reinforcement bracket and install the front cradle support bracket bolts hand tight.

- Torque the front cradle bolt and rear cradle bolts to:

- 90 Nm (60 lb ft)

- plus 180 degrees

- plus 15 degrees

- Torque the front cradle reinforcement bracket bolts to:

- 150 Nm (111 lb ft)

- plus 30 degrees

- plus 15 degrees

- Route the air bag pump electrical connector between the cradle and sway bar and connect.

- Install the ABS sensor.

- Using a support stand or equivalent, compress the suspension to align the strut to the body. Tighten the bolts to 100 Nm (74 lb ft).

- Connect the strut electrical connector.

Note: When re-installing the brake caliper, it may be required to compress the caliper by turning the parking brake cable adjustment screw clockwise at the electric parking brake control module.

- Install the brake caliper.

- Connect the ABS sensor, control module and, if equipped, integrated braking assist electrical connectors to the body side wiring harness.

- Install the rear wheelhouse liner.

- Install the RDCCM. Refer to Rear Differential Clutch Control Module Replacement in SI.

- Connect both wiring harness connectors to the RDCCM.

- Lower the vehicle.

- Re-inflate the suspension air bags. Refer to Air Suspension System Depressurization and Pressurization in SI.

- Clear the codes.

Parts Information

| Description | Part Number | Qty |

| MODULE KIT, RR DIFF CLU CONT | 23183680 | 1 |

| HARNESS, SUSP ACTR WRG | 23459989 L

With COLL IMMINENT BRK-ALL SPEED, VEH FWD MOVEMENT, BRAKE PREFILL, INTEGRATED BRAKE ASSIST |

1 |

| 23459990 L | 1 |

Warranty Information

| Labor Operation | Description | Labor Time |

| 5480348* | Rear Differential Clutch Control Module Replacement

Left side Suspension Wiring Harness |

6.5 hrs** |

| *This is a unique Labor Operation for Bulletin use only.

**Battery charge and test labor time is included with this repair and charging for a battery charge and test separately is subject to debit of the claim. |

||

| Version | 2 |

| Modified | Dec 20, 2016 – Adding the 2017 Model Year, additional RPOs, Middle East to the Involved Region or Country section and Warranty Information. |

SEOCONTENT-END

Bulletin No.: 16-NA-265

Date: Dec-2016

To View or Download this Document Click Here

Loading...

Loading...

Bulletin No.: 16-NA-265

Date: August, 2016

To View or Download this Document Click Here

Loading...

Loading...

| “This site contains affiliate links for which OEMDTC may be compensated” |

- The only full synthetic premium gear oil in a flexible pouch, making it easer to use and work in tight spaces

- Valvoline Extended Protection Flex fill Full Synthetic Gear Oil offers next-level performance with up to 4X better gear wear protection than our conventional formula to maximize gear life

- Meets the demands of conventional and limited slip rear differentials where API GL-5 is specified, as well as non-synchronized manual transmissions that require API GL-4 or MT-1 fluid

- Outstanding thermal stability and high and low temperature protection

- Mobil 1 Synthetic Gear Lube LS is a supreme performance, synthetic, multipurpose, automotive gear lubricant

- Meet or exceed the highest level of performance requirements of many modern passenger vehicles – including limited slip applications

- Helps protect against thermal and oxidative degradation, wear and corrosion, and viscosity loss associated with premature shearing

- Promotes outstanding power transfer performance - even in some of the most severe driving conditions

- Sold as 6 pack

- Viscosity Rating: Offers a viscosity of 75W-90, ensuring optimal performance in a wide temperature range.

- Full Synthetic Composition: Made from synthetic base oils, providing superior lubrication and thermal stability.

- Improved Wear Protection: Reduces wear on gears and bearings, extending the life of drivetrain components.

- Temperature Stability: Maintains performance in extreme temperatures, preventing breakdown and maintaining viscosity.

- High Load Carrying Capacity: Designed to handle heavy loads, making it ideal for demanding applications.

- Mobil 1 Synthetic Gear Lube Ls 75W-90 Mobil 1 Synthetic Gear Lube Ls 75W-90 Is A Supreme Performance, Synthetic, Multi-Purpose, Sae 75W-90 Automotive Gear Lubricant Designed To Meet The Highest Level Of Performance Requirements Of Modern Passenger Vehicles In All Types Of Operating Conditions, Including Limited Slip Applications, As Well As Delivering Outstanding Power Transfer Performance

- Compared To Conventional Hypoid Gear Lubricants, Mobil 1 Synthetic Gear Lube Ls 75W-90 Performs Exceptionally Well Over A Wide Range Of Temperatures

- Through Creativity, Productivity And Innovation - This Brand Continues To Develop The Finest Automotive Accessories

- Model Number : 104361-UNIT

- Fit type: Vehicle Specific

- Affordable solutions

- Replaces OEM number: Lucas Oil: 10047

- Excellent for use in limited-slip differentials

- Packaging May Vary

- Extreme pressure additives deliver outstanding high pressure performance, load carrying capacity and durability for towing and hauling

- Contains a limited slip additive for optimal clutch pack performance

- Daily Protection gear lubricant helps prevent noise and chattering, while protecting gear teeth from wearing out prematurely

- Outstanding high and low temperature protection ranges from -30F to 350F for dependable year-round coverage

- Fights rust and corrosion with corrosion inhibitors and safeguards against impurities, oxidation and thermal breakdown

- Heavy duty

- High performance

- Stands up to high temperatures

- LONGER EQUIPMENT LIFE: 75W-90 GL-5 gear oil is formulated with synthetic base oils and specialty performance additives to provide high-temperature thermal and oxidative stability in a wide range of operating conditions.

- ENHANCED PERFORMANCE IN DIFFERENTIALS: Engineered with specific limited-slip (LS) additives, it eradicates chatter, ensuring seamless functionality in limited-slip differentials for smoother, efficient operation.

- MAXIMUM GEAR PROTECTION: Extreme pressure anti-wear additives safeguard gear teeth from shock loading and high torque, ensuring prolonged gear life and reduced maintenance needs.

- ALL-WEATHER RELIABILITY: U1P 75W-90 Gear Oil guarantees excellent cold temperature flow, ensuring reliable operation in diverse weather conditions.

- COST-EFFECTIVE MAINTENANCE SOLUTION: Exceeding performance benchmarks, it minimizes maintenance costs and extends equipment lifespan, providing a cost-efficient solution for diverse applications.

- Contains extraordinary anti-wear and lubricity agents, ensuring exceptional protection against wear and reducing drag

- Helps to control heat

- Incorporates Lucas cutting-edge additive technology derived from top-rated Lucas Heavy Duty Oil Stabilizer, the number one supplemental oil in the heavy-duty industry

- Available in 1 quart and 1 gallon bottle sizes

Last update on 2025-05-08 / Affiliate links / Images from Amazon Product Advertising API

This product presentation was made with AAWP plugin.