| “This site contains affiliate links for which OEMDTC may be compensated” |

NHTSA ID Number: 10088863

Manufacturer Communication Number: 16-NA-204

Summary

THIS INFORMATIONAL BULLETIN IS A SUPPLEMENT TO THE DURAMAX DIESEL COOLANT SYSTEM FILL AND HEAD GASKET REPLACEMENT PROCEDURE FOUND IN THE SERVICE INFORMATION.

42 Affected Products

Vehicles

| CHEVROLET | SILVERADO 1500 | 2011-2016 |

| CHEVROLET | SILVERADO 2500 | 2011-2016 |

| CHEVROLET | SILVERADO 3500 | 2011-2016 |

| GMC | SIERRA 1500 | 2011-2016 |

| GMC | SIERRA 2500 | 2011-2016 |

| GMC | SIERRA 3500 | 2011-2016 |

| GMC | SIERRA DENALI | 2011-2016 |

SEOCONTENT-START

Bulletin No.: 16-NA-204

Date: June, 2016

| Subject: | Filling the Cooling System, Diagnosing and Replacing Leaking Cylinder Head Gaskets on a 6.6 Duramax Diesel |

| Brand: | Model: | Model Year: | VIN: | Engine: | Transmission: | ||

|---|---|---|---|---|---|---|---|

| from | to | from | to | ||||

| Chevrolet | Express | 2011 | 2016 | Diesel (LGH, LML) | |||

| Silverado | |||||||

| GMC | Savana | ||||||

| Sierra | |||||||

| Involved Region or Country | North America, Israel |

| Condition | This Bulletin is a supplement to the Duramax diesel coolant system fill and head gasket replacement procedure found in the Service Information. |

| Cause | Low coolant in the cooling system may cause damage to the engine. |

Introduction

Warning: Refer to SI for safety precautions when filling cooling systems.

This Bulletin is a supplement to the Duramax diesel Service Information for cooling system filling, Cylinder head gasket diagnosis, and head gasket replacement procedure.

For vehicles that are not low on coolant and have a low coolant light on or a low coolant message, refer to Low Engine Coolant Indicator Always On in SI.

Warning: NEVER remove the radiator cap with the system hot or under pressure causing the solution to boil instantaneously with explosive force. The coolant temperature in the radiator can be considerably higher than the boiling point of the solution at atmospheric pressure. In addition the risk of a burn hazard or serious bodily harm, it will allow air to re-enter the system and the fill process may have to be repeated.

Description and Operation

In an effort to improve general awareness within the service community, this document is being released to further clarify operating characteristics of the cooling system for the 6.6L Duramax Diesel engine. In particular, this document aims to highlight diagnostic steps for addressing concerns of a low coolant condition.

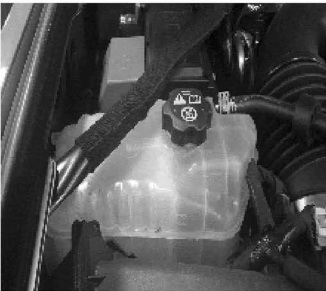

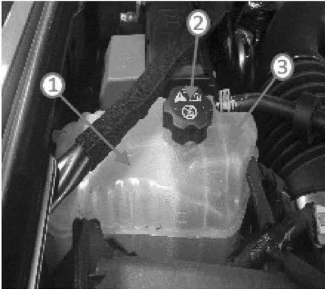

2011-2012 Pick Up Dual Surge Tank

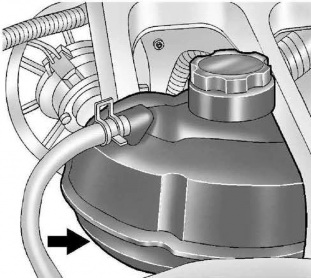

2013-2016 Pick Up Dual Surge Tank

If during the process of filling the surge tank, a leak is detected in the tank or cap on the 2015-2016 Silverado and Sierra, that both components should be replaced per PIT5497.

The Duramax Diesel pickup trucks utilize a re-surge or dual-sided surge coolant expansion tank. This design of the dual-sided tank allows for maximum boil over protection while minimizing coolant loss. This would requires coolant on both sides of the tank in order to properly maintain system pressure.

2010-2012 LGH Van Surge Tank

The Duramax Diesel vans utilize a surge coolant expansion tank.

Vans that utilize rear auxiliary heat, refer to the Service Fill Procedure For Vehicles Equipped With Rear Heater in this bulletin.

Under normal operating conditions, system pressure should be between 5 and 20 psi (34 and 138 kPa).

Service Fill Procedure – Pick Up

Perform an inspection to the cooling system before performing the fill procedures, refer to SI for any repairs that may need to be done to the cooling system.

Note: It is normal for the coolant level to not reach the very top of the bottle until the system has been purged of all air. Fill the coolant to at least the “MIN” line.

- Remove the surge tank cap (2).

- Using a 50/50 mixture of GM Dex-cool antifreeze and water, slowly fill the pressurized side (3) of the surge tank until the system is full of coolant.

- With the surge tank cap removed, start the engine and race it to 2,000 – 2,500 RPM until the engine reaches normal operating temperature.

- Engine should reach an operating temperature of 90°C (194°F) and the upper radiator hose should be HOT.

- Continue to run the engine at 2,000-2,500 RPM for an additional five minutes.

- Allow the engine to idle for five minutes, as you slowly add more coolant to the system.

- Run the engine at 2,000-2,500 RPM for another five minutes.

- With the engine at idle, add coolant as necessary until it reaches the top of the pressurized side of the surge tank.

Fill the overflow side

This section is for vehicles that are equipped with re-surge/dual sided tank.

- After the pressurized side of the surge tank has been completely filled, slowly add coolant to fill the overflow side (1).

- Fill the overflow side to at least one-third capacity, but no more than half full.

- Install the surge tank cap.

Purge Cycle

- After filling the overflow side of the surge tank and installing the surge tank cap, purge any remaining air by running the engine at 2500 RPM for three minutes after the engine has reached operating temperature.

- Shut off the engine and allow to cool completely.

- Squeeze the upper radiator hose to make sure the system is free of pressure.

- Visually inspect the surge tank to ensure the coolant level is full to the top of the pressurized side of the tank and that the overflow side is one third to one half full.

Service Fill Procedure – Van

Perform an inspection to the cooling system before performing the fill procedures, refer to SI for any repairs that may need to be done to the cooling system.

- Remove the surge tank cap.

- Using a 50/50 mixture of GM Dex-cool antifreeze and water, slowly fill the surge tank until the system is full of coolant.

- With the surge tank cap off, start the engine and run it to 2,000–2,500 RPM until the engine reaches normal operating temperature.

- Engine should reach an operating temperature of 90°C (194°F) and the upper radiator hose should be HOT.

- Continue to run the engine at 2,000–2,500 RPM for an additional five minutes, as you slowly add more coolant to the system.

- Allow the engine to idle for five minutes, as you slowly add more coolant to the system.

- Run the engine at 2,000–2500 RPM for another five minutes, as you slowly add more coolant to the system.

- Allow the engine to idle for five minutes, as you slowly add more coolant to the system.

- With the engine at idle, add coolant as necessary until the level is full.

- Install the surge tank cap.

- Shut off the engine.

- Allow the engine to cool.

- Top off the coolant as necessary.

- Rinse away any excess coolant from the engine and engine compartment.

Diesel Engine Cooling System Filling Procedure For Vehicles Equipped With Rear Heater

Note: When filling vehicles that has been up fitted with an auxiliary heater, look for a label from the up fitter with instructions on how to fill the system. If you do not find one, contact the up-fitter and request instructions on the proper way to make sure that all air is out of the auxiliary heater.

Air trapped in the cooling system can cause cavitation which may be damaging to some system components.

When filling the cooling systems on vehicles that have been up-fit with rear heaters, such as ambulances or buses, ensure that the rear heater is purged of all air.

Some vehicles may have the rear heater mounted higher than the coolant bottle. Some rear heater units may have been fitted with shut off valves and/or coolant pumps. It may be necessary to contact the vehicle up-fitter for a procedure to make sure that the rear heater is flowing coolant and all air is purged from the system.

One suggestion to help ensure that all air has been removed from the cooling system is to drive the vehicle through several, up to five, thermal cycles after performing the Vac-N-Fill procedure. While driving the vehicle, make sure there is coolant flowing through the rear heater system. Monitor the coolant level in the surge tank before and after each thermal cycle and add coolant as needed. When the coolant level in the surge tank remains constant before and after the drive cycles, all air should be purged from the system.

Diagnosing a Reoccurring Low Coolant Message on the DIC

If the coolant lamp is on or there are concerns of coolant escaping the overflow side of the surge tank, there are several possible causes:

- External coolant leak. Possible sources to inspect include:

- Lower radiator hose

- Engine block heater

- Water Pump

- Radiator Core

- Engine Oil Cooler

- Air in the cooling system (due to a low fill condition).

- Defective / incorrect radiator cap.

- Damaged cylinder head gasket.

Head Gasket State of Health Check

Warning: If at any time the pressure exceeds 20 psi (138 kPa), shut the engine off and stay clear of the under hood environment until the engine cools. Injury may occur.

Note: In most cases, head gasket failure is most likely the result of operating the engine with a low coolant condition. Ensure that during the repair procedure, particular attention is paid to identify any external coolant leaks.

If there is no evidence of external coolant leakage, it is recommended to diagnose head gasket failure using the following procedure:

- If required, top off engine coolant per procedure outlined in SI. Remember:

- Install pressure gage to surge tank, ensure the appropriate adapter is used.

- After warming the engine to operating temperature, race engine to 2,500 to 3,500 RPM until the thermostats open and the radiator hose is HOT. The pressure gage should stay below 20 psi (138 kPa).

- After the cooling system has built pressure, shut off the engine and allow it to cool.

- The pressure should drop to less than 5 psi (34 kPa).

- If pressure does not dissipate, the head gaskets should be considered suspect.

New Procedure: Pressure Check

Example of Head Gasket – Pass

Engine Cold Start.

Engine Warm Up:

- Run engine at 2500 RPM.

- Validate engine temperature at 85°C (185°F).

- Validate the engine running pressure should read above 15 psi (103 kPa).

End of Test:

New Procedure: Pressure Check

Example of Head Gasket – Fail

Engine Cold Start.

Engine Warm Up:

- Run engine at 2500 RPM.

- Validate engine temperature at 85°C (185°F).

- Validate the engine running pressure should read above 15 psi (103 kPa).

End of Test:

- Allow engine to cool.

- Validate engine pressure above 20 psi (138 kPa) without the pressure dropping.

Head Gasket Preparations

The following are recommendations and best practices to follow during Duramax diesel cylinder head service or gasket replacement:

- The left and right cylinder head gaskets are not interchangeable. Improper placement of the cylinder head gasket will block coolant and oil passages. Blocked coolant and oil passages will cause severe engine damage.

- Do not use any power type sanding devices. Do not use a wire brush or wheel to clean gasket surfaces. Do not use chemical cleaning agents on gasket surfaces. Refer to the latest version of bulletin 00-06-01-012 for more information.

- Refer to Service Information and the latest version of bulletin 06-06-01-006 for engine block and cylinder head sealing surface cleaning procedures.

- During cylinder head servicing or cylinder head gasket replacement always use NEW M12 cylinder head bolts. The M8 cylinder head bolts can be reused.

- Clean the bolt threads and holes

- Leave the gaskets in the packaging until they are ready to install on the block. Once removed from the packaging handle with great care.

- DO NOT set the gaskets on workbenches or toolboxes to avoid possible introduction of foreign debris.

- DO NOT use air to blow between the gasket layers.

- DO NOT machine the cylinder head surface. Measure the cylinder head for warpage with a straight edge and a feeler gauge. A cylinder head block deck with warpage in excess of 0.1 mm (0.0039 in) must be replaced.

- It is recommended to install two head bolts secured to minimal torque (Est. 20 Nm) prior to installing the remaining head bolts. This will minimize the chance of introducing other foreign material during installation.

- It is also recommended to use a paint pen on the M12 cylinder head bolts during installation. Mark the head of each bolt, one by one, indicating which of the 4 torque steps have been completed on that particular bolt. This prevents skipping a step or doing a step twice. In the end, all bolts should have 4 paint pen marks.

- Please follow this diagnostic or repair process thoroughly and complete each step. If the condition exhibited is resolved without completing every step, the remaining steps do not need to be performed.

| Version | 1 |

| Modified |

SEOCONTENT-END

16-NA-204

June, 2016

To View or Download this Document Click Here

Loading...

Loading...

| “This site contains affiliate links for which OEMDTC may be compensated” |

- VERSATILE ENGINE COOLANT: This antifreeze + coolant is designed for use in all GM vehicles 1995 and newer requiring an orange organic acid technology (OAT) coolant. This item contains a bittering agent called Denatonium Benzoate.

- PROTECTS ENGINE: This antifreeze + coolant provides protection against rust and corrosion for all cooling system metals, including aluminum

- LONG-LASTING COOLANT: This antifreeze + coolant has a service life of up to 5 years/150,000 miles with a complete cooling system flush and fill

- BETTER FORMULA: Our antifreeze coolant solution is free of amines, phosphate, borate, nitrite and silicate

- EXCELLENT PERFORMANCE: This meets the performance requirements of ASTM D3306, D4985 and GMW3420, GM6277M

- Unsurpassed freeze protection and anti-boil performance outperforms industry standards

- Organic acid technology resists rust, scale & corrosion while protecting all cooling system metals (including aluminum)

- High-quality additives protect against leaks and won’t harm gaskets, hoses, plastics or original vehicle finish

- Orange concentrate formula should be mixed with clean tap water or demineralized water at 50/50 ratio for temperatures -34 to 265F; 60/40 for -62 to 270F; and 70/30 for -84 to 267F

- 5 year/150,000 mile guarantee protects against engine failure caused by freeze-ups or boil-overs

- Unsurpassed freeze protection and anti-boil performance outperforms industry standards

- Organic acid technology resists rust, scale & corrosion while protecting all cooling system metals (including aluminum)

- High-quality additives protect against leaks and won’t harm gaskets, hoses, plastics or original vehicle finish

- Pre-mixed orange formula is ready-to-use in a 50/50 ratio with deionized water to protect all modern engine components from winter freezing (-34F) and summer boiling (265F).

- 5 year/150,000 mile guarantee protects against engine failure caused by freeze-ups or boil-overs

- ACDelco 10-101 DEX COOL (ORANGE)

- Contains A Bittering Agent

- OEM

- Contains a bittering agent

- ZEREX DEX-COOL antifreeze coolant is approved by General Motors

to the GM 6277M specification

to the GM 6277M specification - ZEREX DEX-COOL antifreeze coolant contains no phosphates, silicates, borates, nitrates, amines and nitrites

- Valvoline ZEREX DEX-COOL antifreeze coolant is a patented* carboxylate formulation with a service life of up to five years or 150,000 miles

- When diluted 50% with water, ZEREX DEX-COOL protects modern engine components from winter freezing and summer boiling

- ZEREX DEX-COOL antifreeze coolant is storage stable for up to five years as both a concentrate or diluted with water

- Protects vital engine parts for up to 5 years/150,000 miles with Extended Life Formula.

- Includes the Prestone protection package that meets environment and scale protection standards for the cooling system.

- Concentrate formula. Must mix with water (distilled ideal) to the desired mix ratio of EG & water. Can be used for top-off, complete drain and refill or flush and refill of the cooling system.

- All GM vehicles 1995 and newer/GM approved (GMC, Chevrolet, Buick

, Cadillac

, Cadillac , Pontiac

, Pontiac , Saturn

, Saturn , Oldsmobile

, Oldsmobile , Hummer

, Hummer ), most Ford

), most Ford vehicles 2011- 2018 (Ford

vehicles 2011- 2018 (Ford , Lincoln, Mercury) and most Chrysler vehicles 2013 and newer (Ram, Dodge, Jeep, Chrys)

, Lincoln, Mercury) and most Chrysler vehicles 2013 and newer (Ram, Dodge, Jeep, Chrys) - Contains bitterant

- High-performance, universal automotive antifreeze/coolant with extended life

- Provides effective, long-term corrosion protection for aluminum, brass, cast iron, steel, solder, and copper

- Superior high temperature for aluminum protection, resulting in longer component life

- Silicate-free formula maintains good as new heat transfer, and reduces silicate gel formation in use or in storage

- Suitable for a 5-year or 150,000 mile service life in automotive applications; up to of 600,000 miles or 12,000 hours in heavy duty applications

- ZEREX DEX-COOL antifreeze coolant is approved to the GM 6277M specification

- ZEREX DEX-COOL antifreeze coolant contains no phosphates, silicates, borates, nitrates, amines and nitrites

- Valvoline ZEREX DEX-COOL antifreeze coolant is a patented* carboxylate formulation with a service life of up to five years or 150,000 miles

- When diluted 50% with water, ZEREX DEX-COOL protects modern engine components from winter freezing and summer boiling

- For any product use or product technical questions call 1-800-TEAM-VAL

- PREDILUTED ANTIFREEZE AND COOLANT: Engineered to support any vehicle's engine cooling system to enhance performance and provide protection. This item contains a bittering agent called Denatonium Benzoate.

- PROPRIETARY BLEND: Contains 10X the scale-fighting inhibitors to ensure maximum cooling performance while protecting against scale, corrosion, and other damage

- SUPERIOR CHEMISTRY: Free from 2-EHA, silicate, nitrite, borate, and amines to keep your vehicle functioning in prime condition

- UNIVERSAL FORMULA: Compatible with any color or type of existing antifreeze and coolant in your car's system

- LONG-LASTING: Offers 2X the average warranty coverage, cooling your engine system for over 10 years or 300,000 miles of service

Last update on 2025-05-08 / Affiliate links / Images from Amazon Product Advertising API

This product presentation was made with AAWP plugin.