| “This site contains affiliate links for which OEMDTC may be compensated” |

July 5, 2016 NHTSA CAMPAIGN NUMBER: 16V507000

Passenger Presence Sensor Wires May Be Damaged

If the wires are damaged, the passenger presence sensory system may fail to recognize that the passenger seat is occupied, disabling the air bag. Damage may also cause the air bag fuse to short resulting in a loss of all air bags and seat belt pretensions. Both conditions increase the risk of injury during a crash.

NHTSA Campaign Number: 16V507

Manufacturer General Motors LLC

LLC

Components AIR BAGS, ELECTRICAL SYSTEM

Potential Number of Units Affected 289,254

Summary

General Motors LLC (GM) is recalling certain model year 2009-2010 Chevrolet Impala vehicles manufactured April 25, 2008 through February 16, 2010. The front passenger seat frame may contact and damage the wires of the passenger presence sensor module.

LLC (GM) is recalling certain model year 2009-2010 Chevrolet Impala vehicles manufactured April 25, 2008 through February 16, 2010. The front passenger seat frame may contact and damage the wires of the passenger presence sensor module.

Remedy

GM will notify owners, and dealers will double wrap the wires with anti-abrasion tape and replace damaged wires as necessary, free of charge. The recall began on August 1, 2016. Owners may contact Chevrolet customer service at 1-800-521-7300. GM’s recall campaign number is 36110.

Notes

Owners may also contact the National Highway Traffic Safety Administration Vehicle Safety Hotline at 1-888-327-4236 (TTY 1-800-424-9153), or go to www.safercar.gov.

Check if your Vehicle has a Recall

SEOCONTENT-START

#36110-01: Product Safety Recall – Passenger Presence Sensor and Instrument Cluster Malfunction – (Jul 21, 2016)

| Subject: | 36110 – 01 Passenger Presence Sensor and Instrument Cluster Malfunction |

| Models: | 2009–2010 Chevrolet Impala |

|---|---|

| Equipped with Passenger Presence System (RPO AL0) |

| Reference Number: | N16203611 | Release Date: | July 2016 |

| GWM Number: | 2036110 | Revision: | 01 |

| Revision Description: This bulletin has been revised to include a copy of the customer notification letter. Please discard all copies of bulletin 36110. | |||

| Attention: | It is a violation of Federal law for a dealer to deliver a new motor vehicle or any new or used item of motor vehicle equipment (including a tire) covered by this notification under a sale or lease until the defect or noncompliance is remedied.

All involved vehicles that are in dealer inventory must be held and not delivered to customers, dealer traded, or used for demonstration purposes until the repair contained in this bulletin has been performed on the vehicle. |

| Make | Model | Model Year | RPO | Description | |

|---|---|---|---|---|---|

| From | To | ||||

| Chevrolet | Impala | 2009 | 2010 | AL0 | Passenger Presence System |

Involved vehicles are marked “open” on the Investigate Vehicle History screen in GM Global Warranty Management system. This site should always be checked to confirm vehicle involvement prior to beginning any required inspections and/or repairs.

| Condition | General Motors has decided that a defect, which relates to motor vehicle safety, exists in certain 2009 – 2010 Chevrolet Impala vehicles. The front passenger seat frame in these vehicles may rub against and damage the wires of the passenger presence sensor (PPS) module, which could cause the PPS system to fail to recognize that the passenger seat is occupied and improperly suppress the front passenger airbag. In addition, the cluster gauges and driver information center (DIC) alerts may intermittently turn off or not function properly. In rare circumstances, the damage to the PPS module could cause the airbag fuse to short, resulting in the loss of all airbags and seat belt pretensioners. Damage and chafing to the wires of the PPS module could prevent the front passenger airbag from deploying in the event of a crash, which could increase the risk of injury to front passengers. If the wire damage to the PPS module is severe enough to short the airbag fuse, it could cause the loss of power to the sensing diagnostic module, which would result in the loss of all airbags and seat belt pretensioners and could increase the risk of injury to vehicle occupants in the event of a crash. has decided that a defect, which relates to motor vehicle safety, exists in certain 2009 – 2010 Chevrolet Impala vehicles. The front passenger seat frame in these vehicles may rub against and damage the wires of the passenger presence sensor (PPS) module, which could cause the PPS system to fail to recognize that the passenger seat is occupied and improperly suppress the front passenger airbag. In addition, the cluster gauges and driver information center (DIC) alerts may intermittently turn off or not function properly. In rare circumstances, the damage to the PPS module could cause the airbag fuse to short, resulting in the loss of all airbags and seat belt pretensioners. Damage and chafing to the wires of the PPS module could prevent the front passenger airbag from deploying in the event of a crash, which could increase the risk of injury to front passengers. If the wire damage to the PPS module is severe enough to short the airbag fuse, it could cause the loss of power to the sensing diagnostic module, which would result in the loss of all airbags and seat belt pretensioners and could increase the risk of injury to vehicle occupants in the event of a crash. |

| Correction | All vehicles will have double wrap class F anti-abrasion tape with 50% overlap added to the wires in the PPS wire harness. For vehicles with wires that are chaffed, dealers will replace the wire if necessary and add anti-abrasion tape to protect it from further wear. |

Parts

| Quantity | Part Name | Part No. |

| As Required | Woven Polyester (PET) Electrical Tape – PN 1089482 | Obtain from Kent Automotive* |

* To obtain the Woven Polyester (PET) Electrical Tape, contact Kent Automotive at 1-888-937-5368 (USA), 1-800-563-1717 (Canada), and request the part number above. Dealers that do not have a Kent Automotive account or representative must advise the Customer Service Representative that the part is being used for this GM bulletin to obtain special bulletin pricing. Do not order from GMCCA.

Warranty Information

| Labor Operation | Description | Labor Time | Trans. Type | Net Item |

| 9102376 | Passenger Presence System (PPS) Harness Repair | 1.0 | ZFAT | * |

| 9102270 | Customer Reimbursement Approved | 0.2 | ZFAT | ** |

| 9102271 | Customer Reimbursement Denied – For USA dealers only | 0.1 | ZFAT | N/A |

Note: To avoid having to “H” route the customer reimbursement transaction for approval, it must be submitted prior to the repair transaction.

* The amount identified in “Net Item” should represent the actual cost of the woven polyester electrical tape (PET), not to exceed, not to exceed $0.85 USD, $1.18 CAD.

** The amount identified in “Net Item” should represent the dollar amount reimbursed to the customer.

Service Procedure

Follow the steps below to wrap the PPS under seat wire harness with Woven Polyester (PET) Electrical Tape. This procedure also includes a wire inspect and if required, repair.

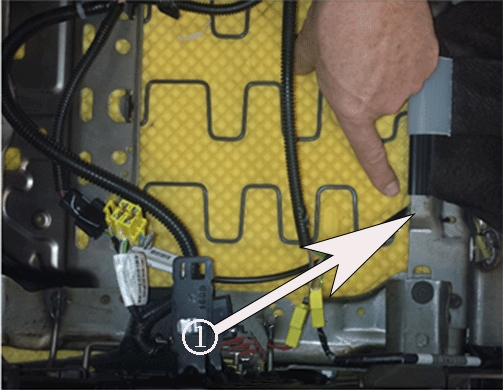

- Inspect the PPS pigtail harness for chafing. Removal of the seat cushion pad with the PPS module and harness may be required to fully inspect the harness. Refer to Inflatable Restraint Passenger Presence System Replacement — Front in SI.

- The picture above shows the bottom of the seat with the front of the seat facing to the left. The location shown (1) is where the PPS harness may come in contact with the seat pan.

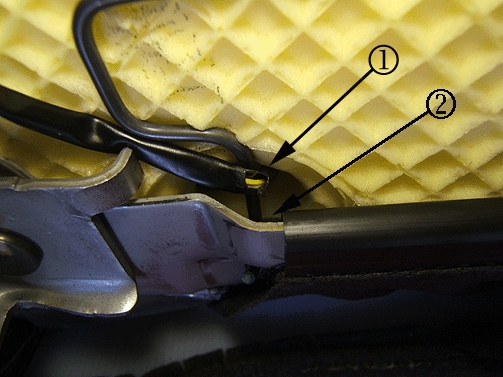

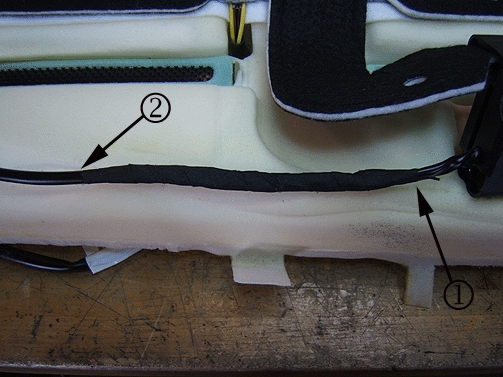

- The picture above illustrates an example of the chafing (1) that may be identified on the PPS harness where it contacts the metal seat pan (2).

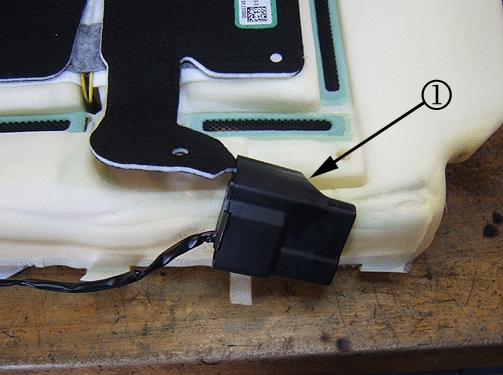

- If the PPS harness shows signs of chafing, examine the wires in the harness carefully. If any wire is broken, shows signs of fraying or damage from an electrical short, repair using SI procedures. Refer to Splicing Copper Wire Using Splice Sleeves in SI. If the yellow wire is one of the damaged wires, please verify proper size airbag fuse is installed within the fuse box. If airbag fuse is open, please replace the airbag fuse. After performing any wiring repairs, proceed to Step 5. If the wire is not broken, frayed or showing damage from an electrical short, but the wire is exposed from the insulation (1) as shown above, proceed to Step 5.

- Remove the PPS module (1) from the seat cushion pad and pull the harness through the cushion

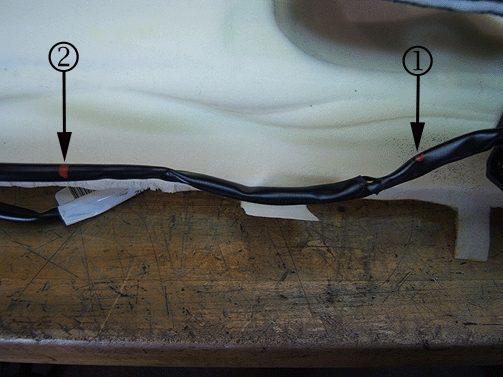

- Mark the harness 30 mm (1.2 in) from the PPS module (1) and 100 mm (4 in) from the first mark (2).

- Tape the PPS harness starting from the mark near the PPS module (1) and extending from that point to the second mark along the harness (2). Ensure that there is a 50% overlap of tape. Once you have reached the 100 mm (4 in) mark, tape back over the first layer of tape to the starting point, creating a double layer of tape.

Important: Ensure that the end of tape finishes on top of itself, and not on the harness. This will prevent the tape from unraveling.

- Reinstall the PPS module into the seat cushion pad.

- Reinstall the seat cushion pad and PPS module into the seat. Refer to Inflatable Restraint Passenger Presence System Replacement – Front in SI.

Dealer Responsibility — For US (US States, Territories, and Possessions)

It is a violation of Federal law for a dealer to deliver a new motor vehicle or any new or used item of motor vehicle equipment (including a tire) covered by this notification under a sale or lease until the defect or noncompliance is remedied.

The US National Traffic and Motor Vehicle Safety Act provides that each vehicle that is subject to a recall of this type must be adequately repaired within a reasonable time after the customer has tendered it for repair. A failure to repair within sixty days after tender of a vehicle is prima facie evidence of failure to repair within a reasonable time. If the condition is not adequately repaired within a reasonable time, the customer may be entitled to an identical or reasonably equivalent vehicle at no charge or to a refund of the purchase price less a reasonable allowance for depreciation. To avoid having to provide these burdensome remedies, every effort must be made to promptly schedule an appointment with each customer and to repair their vehicle as soon as possible. In the recall notification letters, customers are told how to contact the US National Highway Traffic Safety Administration if the recall is not completed within a reasonable time.

Dealer Responsibility — All

All new, used, GM Certified Used, courtesy transportation vehicles, dealer shuttle vehicles, etc. in dealers’ possession and subject to this recall must be held and inspected/repaired per the service procedure of this bulletin before customers take possession of these vehicles. Involved vehicles must be held and not delivered to customers, dealer-traded, released to auction, used for demonstration, or any other purpose.

All GM Certified Used vehicles currently in the dealers’ inventory within the Certified Pre-Owned Inventory System (CPOIS) will be de-certified and must be held and remedied per the service procedure in this bulletin. Upon submitting an accepted/paid warranty transaction in the Global Warranty Management (GWM) system, the vehicle can be re-certified for sale within the CPOIS system, or once again be used in the CTP program.

Dealers are to service all vehicles subject to this recall at no charge to customers, regardless of mileage, age of vehicle, or ownership, from this time forward.

Customers who have recently purchased vehicles sold from your vehicle inventory, and for which there is no customer information indicated on the dealer listing, are to be contacted by the dealer. Arrangements are to be made to make the required correction according to the instructions contained in this bulletin. A copy of the customer letter is provided in this bulletin for your use in contacting customers. Recall follow-up cards should not be used for this purpose, since the customer may not as yet have received the notification letter.

In summary, whenever a vehicle subject to this recall enters your vehicle inventory, or is in your dealership for service in the future, you must take the steps necessary to be sure the recall correction has been made before selling or releasing the vehicle.

Dealer Reports

For dealers with involved vehicles, a listing with involved vehicles has been prepared and will be provided to U.S. and Canadian dealers through the GM GlobalConnect Recall Reports, or sent directly to export dealers. The listing may contain customer names and addresses obtained from Motor Vehicle Registration Records. The use of such motor vehicle registration data for any purpose other than follow-up necessary to complete this recall is a violation of law in several states/provinces/countries. Accordingly, you are urged to limit the use of this report to the follow-up necessary to complete this recall.

Customer Notification

USA & Canada – General Motors will notify customers of this recall on their vehicle (see copy of customer letter included with this bulletin).

will notify customers of this recall on their vehicle (see copy of customer letter included with this bulletin).

Customer Reimbursement

Customer requests for reimbursement of previously paid repairs to correct the condition described in this bulletin are to be submitted to the dealer prior to or by August 31, 2017. See General Motors Service Policies and Procedures Manual, Section 6.1.11 – Product Field Action Customer Reimbursement Procedure (USA & Canada) or local Policies and Procedures, for details.

Service Policies and Procedures Manual, Section 6.1.11 – Product Field Action Customer Reimbursement Procedure (USA & Canada) or local Policies and Procedures, for details.

August 2016

This notice applies to your vehicle, VIN: _____________________________________

Dear General Motors Customer:

Customer:

This notice is sent to you in accordance with the National Traffic and Motor Vehicle Safety Act.

General Motors has decided that a defect, which relates to motor vehicle safety, exists in certain 2009-2010 model year Chevrolet Impala vehicles equipped with a Passenger Presence System. As a result, GM is conducting a safety recall. We apologize for this inconvenience. However, we are concerned about your safety and continued satisfaction with our products.

has decided that a defect, which relates to motor vehicle safety, exists in certain 2009-2010 model year Chevrolet Impala vehicles equipped with a Passenger Presence System. As a result, GM is conducting a safety recall. We apologize for this inconvenience. However, we are concerned about your safety and continued satisfaction with our products.

Important:

|

| Why is your vehicle being recalled? | The front passenger seat frame in your vehicle may rub against and damage the wires of the passenger presence sensor (PPS) module, which could cause the PPS system to fail to recognize that the passenger seat is occupied and improperly suppress the front passenger airbag. Damage and chafing to the wires of the PPS module could prevent the front passenger airbag from deploying in the event of a crash, which could increase the risk of injury to front passengers.

In addition, the cluster gauges and driver information center (DIC) alerts may intermittently turn off or not function properly. The damage to the PPS module could cause the airbag fuse to short, resulting in the loss of all airbags and seat belt pretensioners. If the wire damage to the PPS module is severe enough to short the airbag fuse, it could cause the loss of power to the sensing diagnostic module, which would result in the loss of all airbags and seat belt pretensioners and could increase the risk of injury to vehicle occupants in the event of a crash. |

| What will we do? | Your GM dealer Your GM dealer will add double wrap class F anti-abrasion tape with 50% overlap to the wires in the PPS wire harness. If your vehicle has wires that are chafed, your dealer will replace the wire if necessary and add anti-abrasion tape to protect it from further wear. This service will be performed for you at no charge. Because of service scheduling requirements, it is likely that your dealer will need your vehicle longer than the actual service correction time of approximately 1 hour. |

| What should you do? | You should contact your GM dealer to arrange a service appointment as soon as possible. |

| Did you already pay for this repair? | Even though you may have already had repairs for this condition, you will still need to take your vehicle to your dealer for additional repairs. If you have paid for repairs for the recall condition, please complete the enclosed reimbursement form and present it to your dealer with all required documents. Working with your dealer will expedite your request, however, if this is not convenient, you may mail the completed reimbursement form and all required documents to Reimbursement Department, PO Box 33170, Detroit, MI 48232-5170. The completed form and required documents must be presented to your dealer or received by the Reimbursement Department by August 31, 2017, unless state law specifies a longer reimbursement period. |

| Do you have questions? | If you have questions or concerns that your dealer is unable to resolve, please contact the appropriate Customer Assistance Center at the number listed below. |

| Division | Number | Text Telephones (TTY) |

| Chevrolet | 1-800-630-2438 | 1-800-833-2438 |

| Puerto Rico – English | 1-800-496-9992 | |

| Puerto Rico – Español | 1-800-496-9993 | |

| Virgin Islands | 1-800-496-9994 |

If after contacting your dealer and the Customer Assistance Center, you are still not satisfied we have done our best to remedy this condition without charge and within a reasonable time, you may wish to write the Administrator, National Highway Traffic Safety Administration, 1200 New Jersey Avenue, SE, Washington, DC 20590, or call the toll-free Vehicle Safety Hotline at 1.888.327.4236 (TTY 1.800.424.9153), or go to https://www.safercar.gov. The National Highway Traffic Safety Administration Campaign ID Number for this recall is 16V507.

Federal regulation requires that any vehicle lessor receiving this recall notice must forward a copy of this notice to the lessee within ten days.

Jeffrey M. Boyer

Vice President

Global Vehicle Safety

GM Recall 36110

SEOCONTENT-END

2 Affected Products

Vehicle

| CHEVROLET | IMPALA | 2009-2010 |

15 Associated Documents

Manufacturer Notices(to Dealers,etc) – Date: July 21, 2016 Subject: 36110-01 – Safety Recall Passenger Presence Sensor and Instrument Cluster Malfunction Customer Letter Added

Loading...

Loading...

Recall Acknowledgement

RCAK-16V507-1223.pdf 247.469KB

Loading...

Loading...

Defect 573 Report

RCLRPT-16V507-6137.PDF 216.543KB

Loading...

Loading...

Manufacturer Notices(to Dealers,etc) – Date: June 29, 2016 Subject: 36110 – Safety Recall Passenger Presence Sensor and Instrument Cluster Malfunction

Loading...

Loading...

Safety Bulletin – Reference Number: N16203611 Release Date: June 2016

RCSB-16V507-7221.pdf 440.952KB

To View or Download this Document Click Here

Loading...

Loading...

Safety Bulletin – Reference Number: N16203611 Release Date: July 2016 Revision: 01

RCSB-16V507-1563.pdf 482.443KB

To View or Download this Document Click Here

Loading...

Loading...

ISSUED Owner Notification Letter(Part 577)

RCONL-16V507-8589.pdf 234.348KB

Loading...

Loading...

Recall Quarterly Report #1, 2016-3

RCLQRT-16V507-7703.PDF 214.53KB

Loading...

Loading...

Recall Quarterly Report #6, 2017-4

RCLQRT-16V507-6732.PDF 215.052KB

Loading...

Loading...

May 4, 2017 Subject: Clarification on Quarterly Report Figures Recall 16V507 (GM 36110)

RMISC-16V507-2638.pdf 82.489KB

Loading...

Loading...

October 30, 2017 Subject: Clarification on Quarterly Report Figures Recall 16V507 (GM 36110)

RMISC-16V507-3576.pdf 82.721KB

Loading...

Loading...

Recall Quarterly Report #3, 2017-1

RCLQRT-16V507-9551.PDF 214.749KB

Loading...

Loading...

Recall Quarterly Report #4, 2017-2

RCLQRT-16V507-6612.PDF 214.845KB

Loading...

Loading...

July 31, 2017 Subject: Clarification on Quarterly Report Figures Recall 16V507 (GM 36110)

RMISC-16V507-0256.pdf 82.768KB

Loading...

Loading...

Recall Quarterly Report #5, 2017-3

RCLQRT-16V507-2556.PDF 214.962KB

Loading...

Loading...

Latest Recalls Documents

| “This site contains affiliate links for which OEMDTC may be compensated” |

- High temp Wire Harness Automotive Cloth Tape with excellent sound and rattle dampening performance. Lessens coil whining and lasts well against elevated temperatures (-40℉ - 257℉).

- Sports a race-spec heavy-duty bundling performance but cleanly tears with just bare hands, EMPOWERING average car owners with LITTLE TO NO EXPERIENCE in automotive maintenance to achieve PROFESSIONAL-GRADE results in function and form.

- This Wire Loom Tape features an extremely strong adhesive but does not turn into a messy goo. Rated to last up to 6 years and can easily get you through 150k miles of mileage.

- Its bi-directional weave makes it puncture-resistant and abrasion and corrosion-resistant. This automotive felt tape preserves cables in their pristine condition.

- This engine tape wrap is similar, if not better, in thickness, tensile strength and looks with OEM wire harness tapes. Extra-sticky adhesive enables users to bundle hard-to-reach cables quickly.

- Widely application: The material of wire harness cloth tape is soft and corrosion-resistant, which is suitable for the use of wire harness in automobile interior noise reduction part, such as wire harness of the dashboard, main harness wound and applied for wire joint and wire fixing; It can also sort out home appliance wiring and more

- Easy to tear: Just stick one end of tape to cable, start pulling and wrapping onto the cable and tear it gently; No need scissors and other tools; You can decide the length of the wire cloth tape according to you needs

- Professional cloth tape material: It is made of polyester non-woven fabric and strong acrylic pressure sensitive adhesive; High viscosity, high temperature resistance ( -40°F to 221°F ), well seal and excellent flexibility

- Excellent performance: The wiring harness tape maintains features high adhesive force, good noise reduction, hand tearable and heat insulation performance, and wear resistance; It is suitable for electrical automotive engine and circuit maintenance to achieve the purpose of insulation protection

- Specification: A set of 5 rolls wire harness cloth tap; SIZE: Each roll black electrical harness tape is 50 FT long and 3/4 inch wide; It is work for your different daily needs in diversified use scenarios

- Harness Cloth Tape Application: Suitable for the use of internal wiring harness of automobiles and can reduce the noise. Such as the wire harness of the dashboard.

- Harness Cloth Tape Material: These wiring harness tape are made of high quality cotton flannel and strong adhesive glue.

- Harness Cloth Tape Features: 1High Adhesive Force 2 Noise Resistance Well 3 Strong Abrasion Resistance 4 Hand Tearable 5 Strong Chemical Resistance.

- Harness Cloth Tape Size: Length 15 m, Width 15 mm.

- Car harness cloth tape is very convenient to use; just wrap the tape around the wire and gently tear it apart. No scissors or other tools are needed. The length of the tape can be determined according to your needs.

- Enough to Use: you will get 2 rolls of wire harness tapes in the package, measuring approx. 2 inches x 49.2 ft/ 50 mm x 15 m for each; The proper size and sufficient length is suitable for your different daily needs in many use scenarios

- Safe Material: the wire harness tape is made of polyester non woven fabric material, quality pressure sensitive adhesive, high temperature and wear resistance, which can be applied for a long time

- Nice Performance: the adhesive fabric tape has nice noise reduction and heat insulation performance, very suitable for automotive engine and circuit maintenance to achieve the purpose of insulation protection

- Easy to Use: the wire loom tape is simple and convenient to use, just wrap the tape on the wire and tear it gently, and you can decide the length of the tape according to your own needs

- Scope of Usage: the cloth electrical tape is suitable for automobile interior noise reduction part, such as instrument panel harness and main harness wound, and can also be applied for wire joint and wire fixing

- High Temp Wire Harness Tape: Withstands -40℉ to 250℉, providing soundproofing and vibration dampening.

- OEM-Grade Adhesion: Meets or exceeds OEM standards with strong adhesive for easy cable bundling.

- Easy to Use: Tear by hand—no scissors needed. Flexible for quick adjustments.

- Durable Protection: Resists punctures, abrasion, and corrosion to keep cables intact.

- Multi-Purpose: Ideal for automotive wiring, appliance cords, and household use.

- HIGHLY DURABLE: Designed for automotive wire protection, tesa 51036 PET cloth tape delivers superior abrasion protection and withstands high temperatures and demanding environmental conditions.

- SECURE CLOSURE: The solvent-free, advanced acrylic adhesive (triple A) is highly resistant to flagging and ensures a reliable closure.

- EASY TO USE: Can be used for both manual and automatic applications, this tape features a consistent unwind force and a flexible backing for a smooth application, ensuring an efficient installation process.

- APPLICATIONS: Specially designed for bundling and wire protection against abrasion in automotive engine compartments with demanding temperature-related and environmental conditions.

- SPECIFICATIONS: This tape measures 19 mm wide by 25 m long with a 10.2 mil thickness. It resists temperatures from -40 F to 302 F. Abrasion Resistance (5mm mandrel, LV312) Class D, Abrasion Resistance (10mm mandrel, LV312) Class D, Noise Damping (LV312) Class A.

- Speaker wire harness tape dimensions: 2 Rolls, Length 50ft,Width 15mm.

- Wire Harness Tape Material: These wire harness tapes are made of high quality cotton flannel and strong adhesive.

- Features of loom wire harness tape: strong loom tape, no harmful substances, reduced noise, strong anti-aging ability, strong surface resistance, high high temperature stability. Pressure-sensitive acrylic adhesive that is flame retardant to temperatures up to 225°F (107°C) and remains extremely flexible even below freezing.

- Wiring harness tape application: Suitable for the use of wiring harnesses inside cars to reduce noise. For example, the wiring harness for the instrument panel.

- Car wiring harness tape is very easy to use: just wrap the tape around the wires and gently peel it off. No scissors or other tools required. The length of the tape can be determined according to your needs.

- 1.【High-Temp Automotive Cloth Tape】 Wire Harness Tape offers exceptional sound and rattle dampening performance, reducing coil whining and enduring high temperatures ranging from -40°F to 257°F.

- 2.【Flame Retardant & Convenient & Reliability】Guarantee wires well insulating and protecting, Highly flexible, stretchy and conformable.

- 3.【Heavy-Duty Bundling Tape】Made from durable polyester fabric with a bi-directional weave finish, this tape tears cleanly by hand. It enables novice car owners to achieve race-spec bundling results effortlessly.

- 4.【Long-Lasting Wire Loom Tape】Engineered with a robust adhesive, this tape stays clean, offering 6-year longevity and safeguarding over 150k miles of mileage.

- 5.【Puncture-Resistant Wire Loom Tape】: With a bi-directional weave, this tape is resistant to punctures, abrasions, and corrosion, effectively preserving cables and keeping them in pristine condition.

- Effective Noise Suppression: WELSTIK Wiring Harness Tape provides superior noise reduction, ensuring a quiet and enjoyable driving experience by suppressing unwanted vibrations and sounds in your vehicle's wiring system.

- Enhanced Cable Protection: Designed specifically for automotive use, this fabric tape offers excellent protection for your car's wiring harness. It safeguards against abrasion, moisture, and other environmental factors, ensuring the longevity and reliability of your electrical connections.

- Easy Tear Design: With its user-friendly design, the WELSTIK Wiring Harness Tape can be easily torn by hand, eliminating the need for additional tools and simplifying the installation process. This feature allows for quick and hassle-free application, saving you time and effort.

- Durable and Corrosion Resistant: Crafted from high-quality materials, this wire tape is built to last. It is resistant to corrosion, ensuring long-term performance and reliability even in harsh automotive environments.

- Residue-Free Removal: When it's time to replace or reconfigure your wiring, the WELSTIK Wiring Harness Tape can be easily removed without leaving behind any residue or adhesive marks. This makes maintenance and modifications convenient and clean.

- High Temp Durable Performance: Withstands temperatures from -40℉ to 257℉, making this wire harness tape ideal as an automotive tape for engine compartments. This cloth tape resists abrasion and corrosion.

- Noise Dampening Wire Loom Tape: Reduces coil whining and vibrations for quieter cabins, dashboards, and machinery. This cloth electrical tape provides heavy-duty bundling and insulation.

- Residue-Free: Our heat shrink tape features a strong adhesive that bonds securely without leaving a sticky residue. Rated to last up to 6 years, this wiring harness tape ensures reliable, mess-free performance.

- Flexible and Easy to Use Automotive Tape: This high temp tape tears cleanly by hand for quick application, ideal for DIYers and professionals. This fabric electrical tape is perfect for bundling and insulating household wires.

- Weatherproof and Flame Retardant: Our wire tape resists UV, moisture, and extreme temperatures for year-round protection in high-heat areas like engine compartments.

Last update on 2025-05-08 / Affiliate links / Images from Amazon Product Advertising API

This product presentation was made with AAWP plugin.

What actual parts are involved in the instrument cluster malfunction?

Airbag lights