| “This site contains affiliate links for which OEMDTC may be compensated” |

NHTSA ID Number: 10089226

Manufacturer Communication Number: 08-06-01-011K

Summary

THIS TECHNICAL BULLETIN PROVIDES A PROCEDURE TO PERFORM VARIOUS CHECKS AND REPAIRS TO CORRECT A CUSTOMER OF MALFUNCTION INDICATOR LAMP ON AND DTCS SET.

51 Affected Products

Vehicles

BUICK | BUICK | 9999 |

BUICK | ENCLAVE | 2008-2010 |

BUICK | LACROSSE | 2007-2010 |

CADILLAC | CTS | 2007-2008, 2010 |

CADILLAC | SRX | 2008-2010 |

CADILLAC | STS | 2007-2009 |

| CHEVROLET | CAMARO | 2010 |

| CHEVROLET | CHEVETTE | 9999 |

| CHEVROLET | EQUINOX | 2008-2010 |

| CHEVROLET | MALIBU | 2008-2010 |

| CHEVROLET | TRAVERSE | 2009-2010 |

| GMC | ACADIA | 2007-2010 |

| GMC | GMC TRUCK | 9999 |

PONTIAC | G6 | 2007, 2009-2010 |

PONTIAC | G8 | 2008-2009 |

PONTIAC | TORRENT | 2008 |

SATURN | AURA | 2007-2010 |

SATURN | OUTLOOK | 2007-2010 |

SATURN | SATURN | 9999 |

SATURN | VUE | 2007-2010 |

Parts Information

Please check your part catalog for the cylinder head replacement part number and order accordingly, based on the year, model and applications.

| Washer, Camshaft Thrust

(2 required per head) | 12630941 |

| (Aisin Actuator 5 Screw Design) | |

| 12632859 | |

| (Delphi Actuator 4 Screw Design) | |

| Camshaft Assembly, Exhaust (Left) | 12609249 |

| (LY7 High Output Enclave, Acadia, Traverse, OUTLOOK, ) | |

| Camshaft Assembly, Intake (Left) | 12609250 |

| (LY7 High Output Enclave, Acadia, Traverse, OUTLOOK) | |

| Camshaft Assembly, Exhaust (Right) | 12604375 |

| (LY7 High Output Enclave, Acadia, Traverse, OUTLOOK) | |

| Camshaft Assembly, Intake (Right) | 12609252 |

| (LY7 High Output Enclave, Acadia, Traverse, OUTLOOK) | |

| Cylinder Head Bolt

(8 required per head) | 11518863 |

| Fuel Injection Fuel Rail Crossover Tube | 12591003 |

| (LLT Only) | |

| Fuel Feed Intermediate Pipe | 12591197 |

| (LLT Only) |

SEOCONTENT-START

#08-06-01-011K: Malfunction Indicator Lamp On – Check Engine Light, DTCs P0011, P0014, P0021, P0024, P0341, P0346, P0366 or P0391 Set (Check Camshaft End Play and Perform Action as Outlined) – (Jun 15, 2016)

| Subject: | Malfunction Indicator Lamp On – Check Engine Light, DTCs P0011, P0014, P0021, P0024, P0341, P0346, P0366 or P0391 Set (Check Camshaft End Play and Perform Action as Outlined) |

| Models: | 2007-2009 Buick LaCrosse, Allure (Canada Only) LaCrosse, Allure (Canada Only) |

2007-2010 Buick Enclave Enclave |

|

2010 Buick LaCrosse LaCrosse |

|

2007-2010 Cadillac CTS Sedan, CTS Sport Wagon, SRX, STS CTS Sedan, CTS Sport Wagon, SRX, STS |

|

| 2008-2010 Chevrolet Equinox, Malibu | |

| 2009-2010 Chevrolet Traverse | |

| 2010 Chevrolet Camaro | |

| 2007-2010 GMC Acadia | |

2007-2010 Pontiac G6 G6 |

|

2008-2009 Pontiac G8, Torrent G8, Torrent |

|

2007-2010 Saturn AURA, OUTLOOK AURA, OUTLOOK |

|

2008-2010 Saturn VUE VUE |

|

| Equipped with 2.8L or 3.6L High Feature V6 Engine (VINs D, T, V, 7 – RPOs LP1, LLT, LY7) | |

| Attention: | This Bulletin also applies to any of the above models that may be Export from North America vehicles. |

This Bulletin has been revised to update the Note in Step 7 of the Correction table. Please discard Corporate Bulletin Number 08-06-01-011J.

Condition

Some customers may comment that the check engine light is on.

Upon investigation, the technician may find one or more of the following DTCs stored:

- P0011

- P0014

- P0021

- P0024

- P0341

- P0346

- P0366

- P0391

Correction

| Step | Action | Yes | No |

| 1 | Is the vehicle an Acadia, Enclave, Traverse or Outlook with P0011, P0014, P0021 or P0024? | Go to Step 2 | Go to Step 3 |

| 2 | Reprogram the ECM. Refer to Service Bulletin 08-06-04-011 for further information.

Do P0011, P0014, P0021 or P0024 still set? |

Go to Step 3 | Return vehicle to customer |

| 3 | Important: The set DTC will determine which camshafts (bank 1 or bank 2) should be checked.

Remove the camshaft cover and check camshaft end play on both camshafts in the suspect head using one of the methods listed below. Is camshaft end play equal to or over 0.40 mm (0.016 in)? |

Go to Step 5 | Go to Step 4 |

| 4 | Continue diagnosis using SI and call GM Technical Assistance, if necessary. | – | – |

| 5 | Check the gap between BOTH camshaft position actuators and the front camshaft cap using the Camshaft Position Actuator to Front Camshaft Cap Measurement Procedure listed below.

Does the 2.0 mm (Delphi 4 screw actuator) or 2.5 mm (Aisin 5 screw actuator) hex (allen) wrench fit between the position actuator and cap? |

Go to Step 7 | Go to Step 6 |

| 6 | Install the camshaft thrust washers using the Camshaft Thrust Washer Installation Procedure listed below.

See parts table for correct trust washer part number: Delphi vs Aisin design. |

– | – |

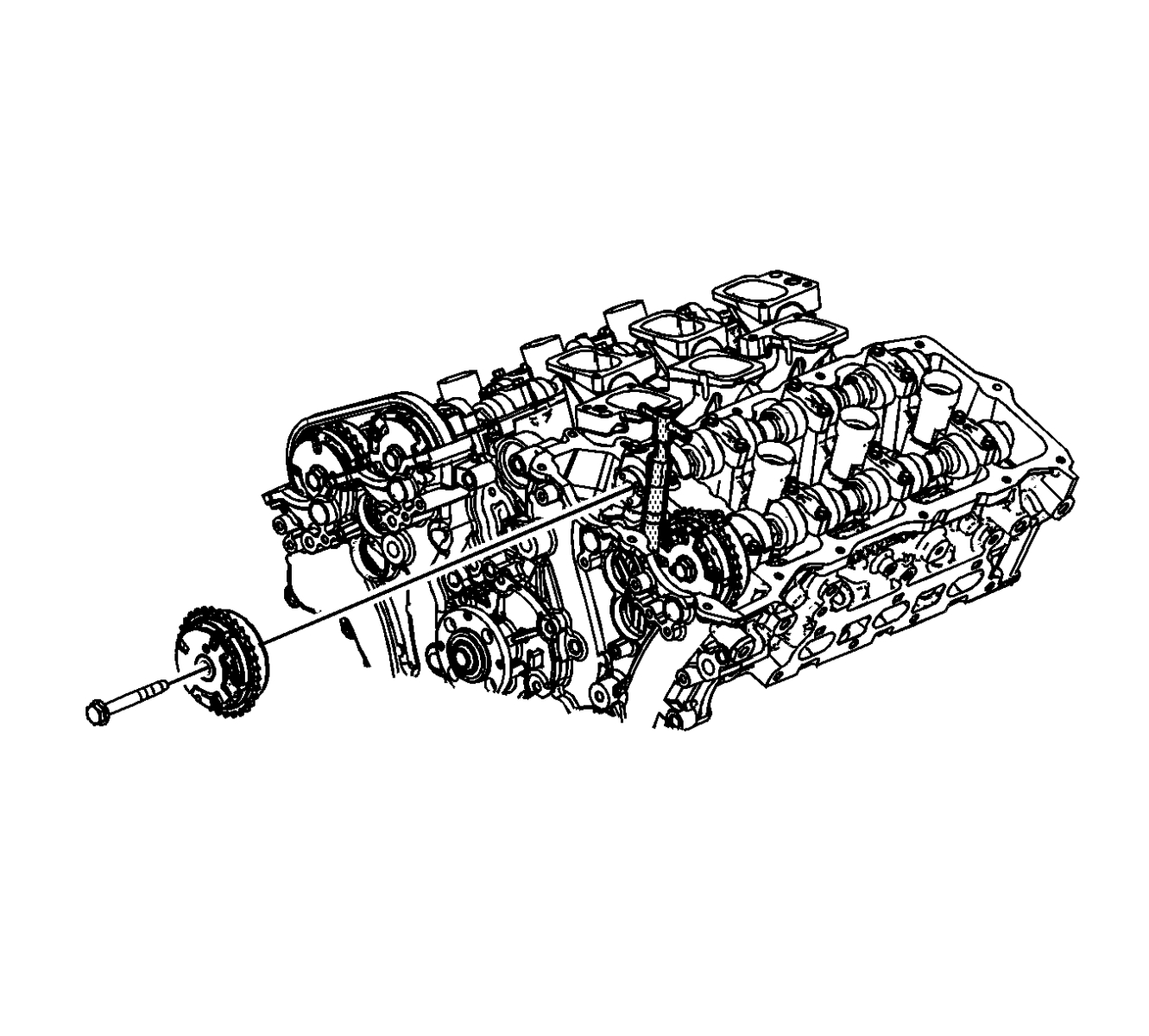

| 7 | Note: There are two generations of replacement service cylinder heads. New design cylinder heads do not use the thrust washers. Reference the parts catalog or Bulletin 16-NA-085 for identification. A instruction sheet is also provided with the new design cylinder head.

Replace the cylinder head and install thrust washers using the Camshaft Thrust Washer Installation Procedure listed below. See parts table for correct trust washer part number: Delphi vs Aisin design. |

– | – |

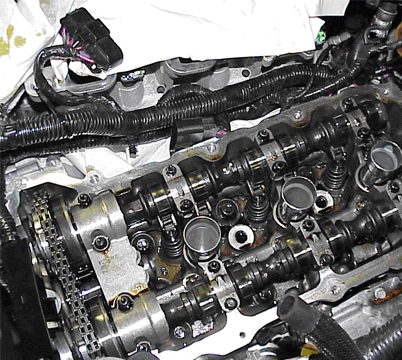

Camshaft End Play Measurement Procedure

Remove the camshaft cover from the suspect cylinder head.

Two methods for measuring camshaft end play:

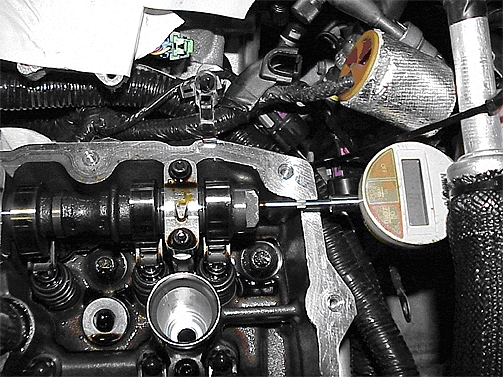

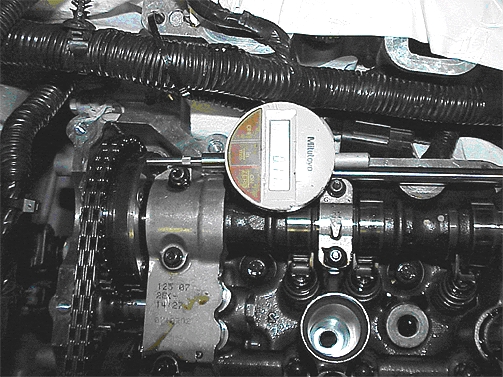

Method 1: Dial Indicator

- Set-up a dial indicator on the camshaft to be measured. Set the dial indicator to measure the axial movement of the camshaft. To minimize measurement error, the dial indicator needs to be on the same axis as the camshaft. A magnetic mount can be placed on the frame rail or a piece of steel plate can be bolted to the top of the head as a reference surface for the dial indicator. The dial indicator should have 0.1 mm (0.001 in) of resolution.

- Position a screwdriver or small pry bar between the camshaft cap and camshaft lobe. Apply force to move the camshaft rearward.

- Be cautious not to damage the camshaft lobe while applying this force.

- Zero the dial indicator.

- Apply force to move the camshaft forward (towards the camshaft phasers).

- Read the dial indicator. This is the end play of the camshaft shaft.

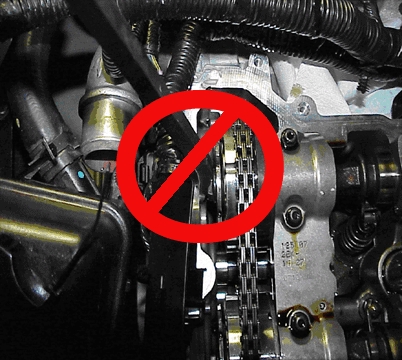

Notice: Do not use the phaser bolt as a pry point. This may cause damage to the camshaft sensor target wheel or the head to camshaft cover sealing surface.

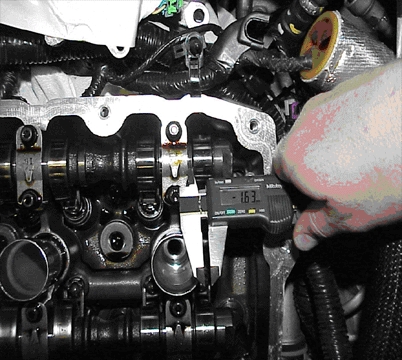

Method 2: Caliper

The caliper should have 0.1 mm (0.001″) of resolution.

- Position a screwdriver or medium pry bar between the camshaft cap and camshaft lobe. Be cautious not to damage the camshaft lobe while applying this force.

- Apply force to move the camshaft rearward.

- Measure and record the distance between the camshaft cap and the camshaft lobe.

- Re-measure and record the distance between the camshaft cap and camshaft lobe. Subtract the two readings; this is the camshaft shaft end play.

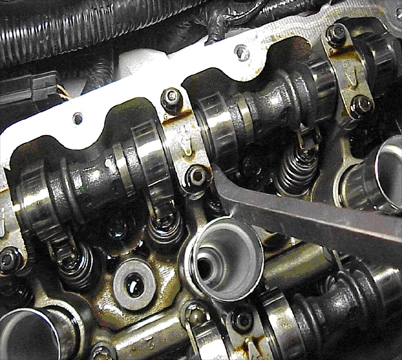

Camshaft Position Actuator to Front Camshaft Cap Measurement Procedure

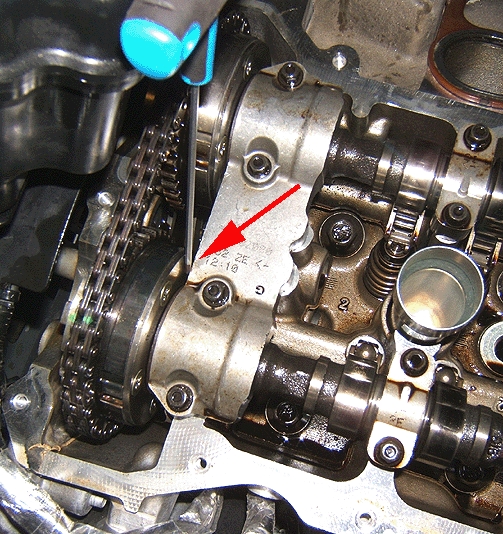

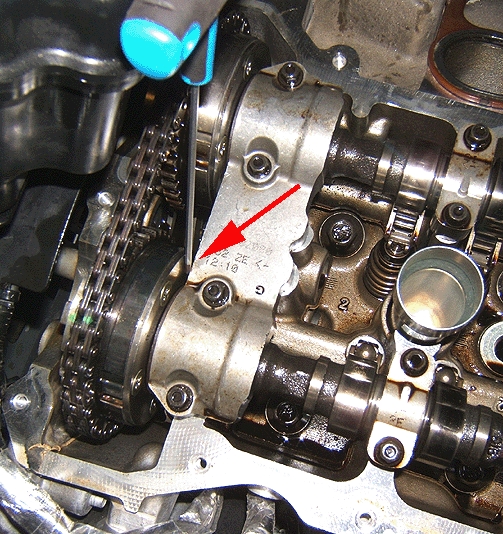

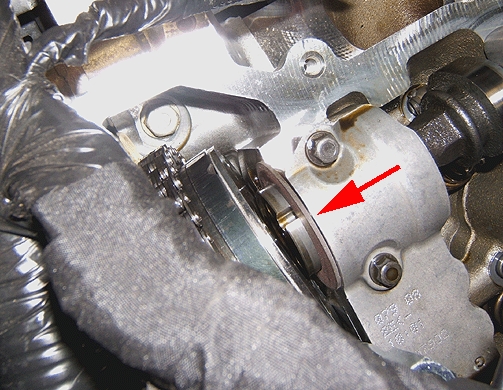

Important: Before performing this procedure, inspect the rear of the camshaft position actuator. Refer to the pictures below to determine which actuator is installed on the vehicle. Use the appropriate procedure listed below.

Aisin Actuator (5 Screw Design, Use 2.5 mm Hex Wrench)

Delphi Actuator (4 Screw Design, Use 2.0 mm Hex Wrench)

5 Screw Aisin Design Actuator

Use a 2.5 mm hex (allen) wrench as a determination gauge to measure the gap between the rear of the camshaft position actuator and the front camshaft cap of both camshafts of the suspect head.

- Position a screwdriver or medium pry bar between the camshaft cap and camshaft lobe.

- Apply force to move the camshaft FORWARD. Be cautious not to damage the camshaft lobe while applying this force.

- With the camshaft moved fully FORWARD, try to insert the 2.5 mm hex (allen) wrench between the intake camshaft position actuator and the front camshaft cap. It may be necessary to turn the wrench to align the flat sides of the wrench with the gap between the actuator and the cap.

- If the wrench fits between the camshaft position actuator and the front camshaft cap, it will be necessary to replace the cylinder head assembly. WHEN REPLACING THE CYLINDER HEAD, ALSO INSTALL A THRUST WASHER BETWEEN EACH CAMSHAFT POSITION ACTUATOR AND THE FRONT CAMSHAFT CAP. See parts table for correct trust washer part number: Delphi vs Aisin design.

- If the wrench DOES NOT fit between the camshaft position actuator and the front camshaft cap, install the camshaft thrust washers between BOTH camshaft position actuators and the front camshaft cap on the suspect head. Follow the Camshaft Thrust Washer Installation procedure below. See parts table for correct trust washer part number: Delphi vs Aisin design.

4 Screw Delphi Design Actuator

Use a 2.0 mm hex (allen) wrench as a determination gauge to measure the gap between the rear of the camshaft position actuator and the front camshaft cap of both camshafts of the suspect head.

- Position a screwdriver or medium pry bar between the camshaft cap and camshaft lobe.

- Apply force to move the camshaft FORWARD. Be cautious not to damage the camshaft lobe while applying this force.

- With the camshaft moved fully FORWARD, try to insert the 2.0 mm hex (allen) wrench between the intake camshaft position actuator and the front camshaft cap. It may be necessary to turn the wrench to align the flat sides of the wrench with the gap between the actuator and the cap.

- If the wrench fits between the camshaft position actuator and the front camshaft cap, it will be necessary to replace the cylinder head assembly and replace both actuators. It is not necessary to replace the camshaft position actuators on the cylinder head that is not being replaced. WHEN REPLACING THE CYLINDER HEAD, ALSO INSTALL A THRUST WASHER BETWEEN EACH CAMSHAFT POSITION ACTUATOR AND THE FRONT CAMSHAFT CAP. See parts table for correct trust washer part number: Delphi vs Aisin design.

- If the wrench DOES NOT fit between the camshaft position actuator and the front camshaft cap, install the camshaft thrust washers between BOTH camshaft position actuators and the front camshaft cap on the suspect head. Follow the Camshaft Thrust Washer Installation procedure below. See parts table for correct trust washer part number: Delphi vs Aisin design.

Camshaft Thrust Washer Installation Procedure

Special Tools

- EN 48313 Timing Chain Retention Tool (2009 and Prior – Both Heads, 2010 LAU Engine – Both Heads, 2010 – Left Head Only)

- EN 49982 Timing Chain Retention Tool (2010 – Right Head Only)

Tip: The cylinder head gasket kit contains all the gaskets and seals necessary to perform this repair.

- Disconnect the engine wiring harness electrical connectors from the intake and exhaust camshaft position (CMP) actuator solenoid valves and sensors.

- Remove the intake and exhaust CMP sensor bolts and sensors.

- Remove the intake and exhaust CMP actuator solenoid valve bolts and valves.

Important: Rotate the crankshaft balancer bolt in a clockwise direction ONLY.

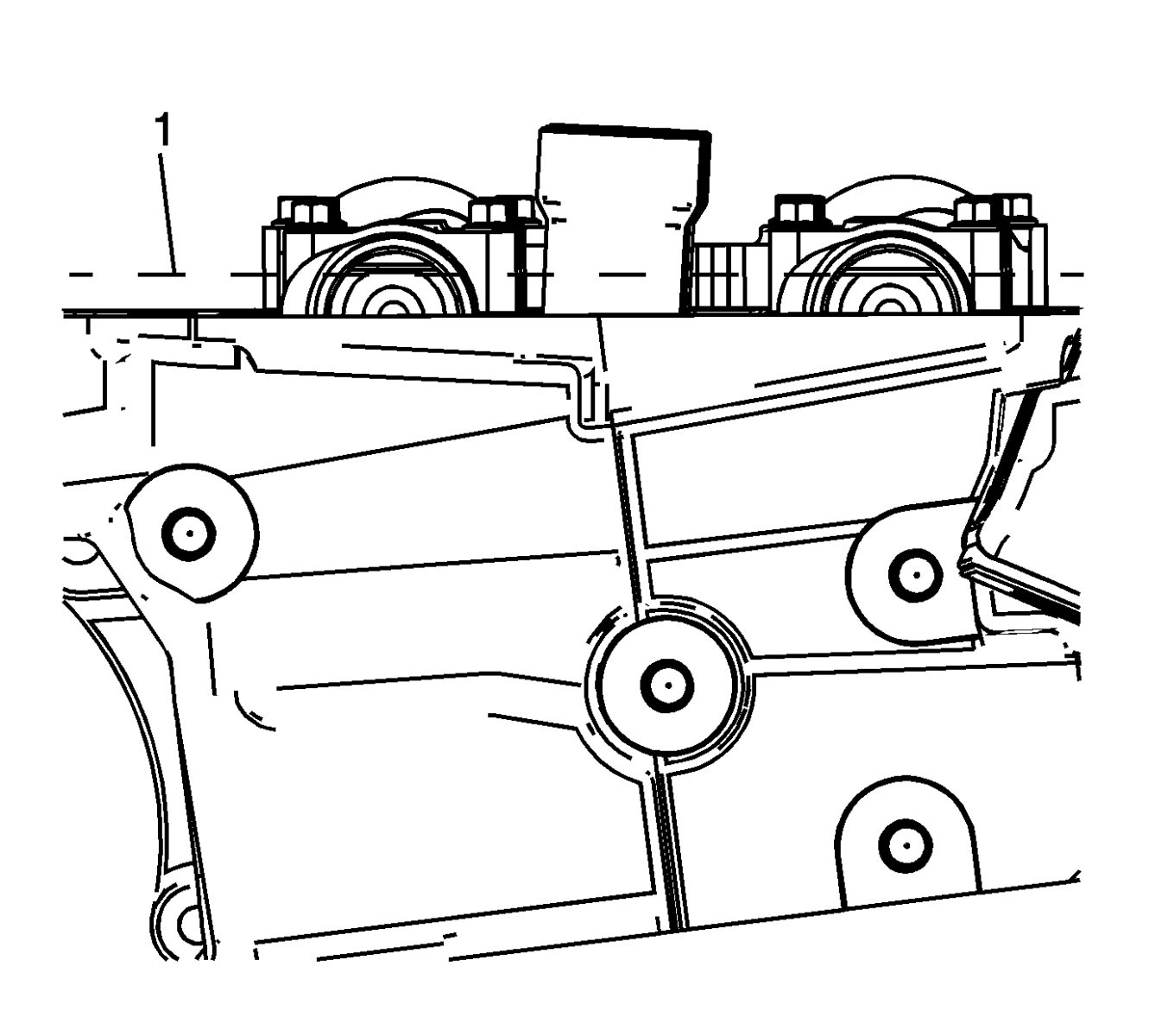

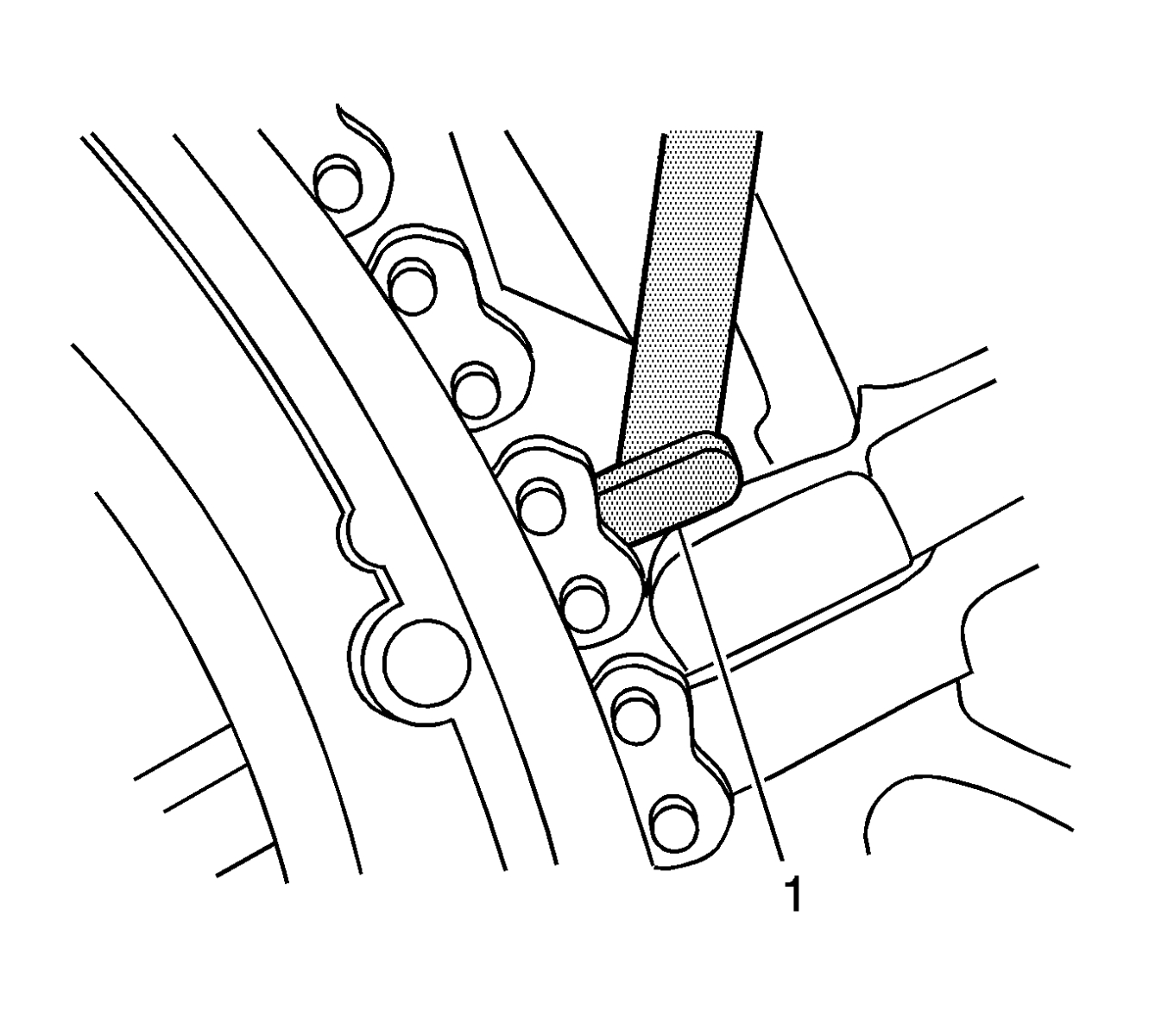

- Rotate the crankshaft balancer using the balancer bolt until the camshafts are in a neutral (low tension) position. The flats on the rear of the camshafts will be parallel with the camshaft cover rail (1).

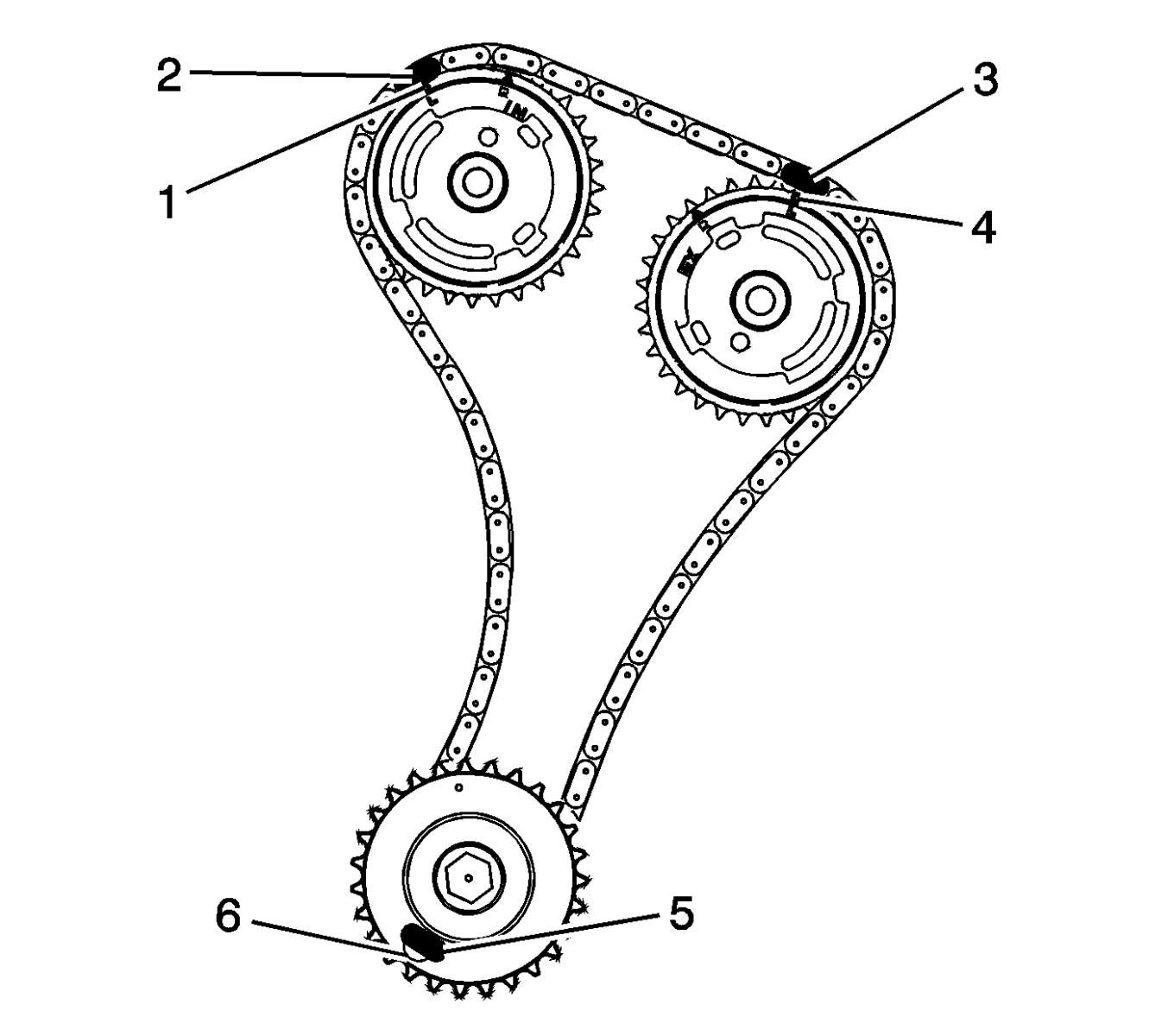

- Use a paint stick to create an alignment mark on one of the timing chain links (2) and the adjacent tooth on the exhaust camshaft position actuator (1).

- Use a paint stick to create an alignment mark on one of the timing chain links (3) and the adjacent tooth on the intake camshaft position actuator (4).

- Use an open end wrench on the hex cast into the camshaft in order to prevent engine rotation when loosening the camshaft position actuator bolts. Slightly loosen the camshaft position actuator bolts. DO NOT remove the bolts.

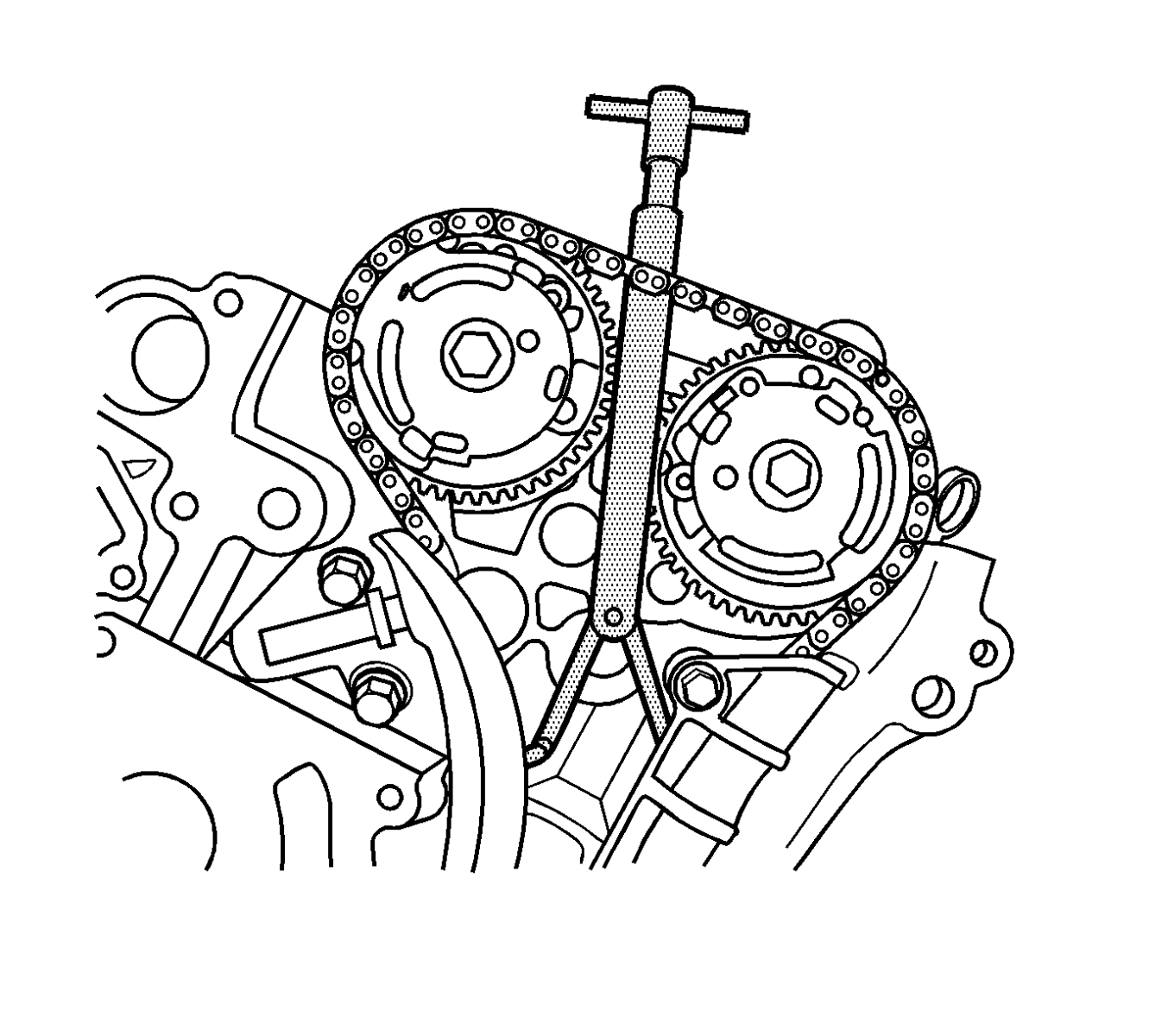

- Unscrew the Timing Chain Retention Tool so that the legs of the tool are retracted.

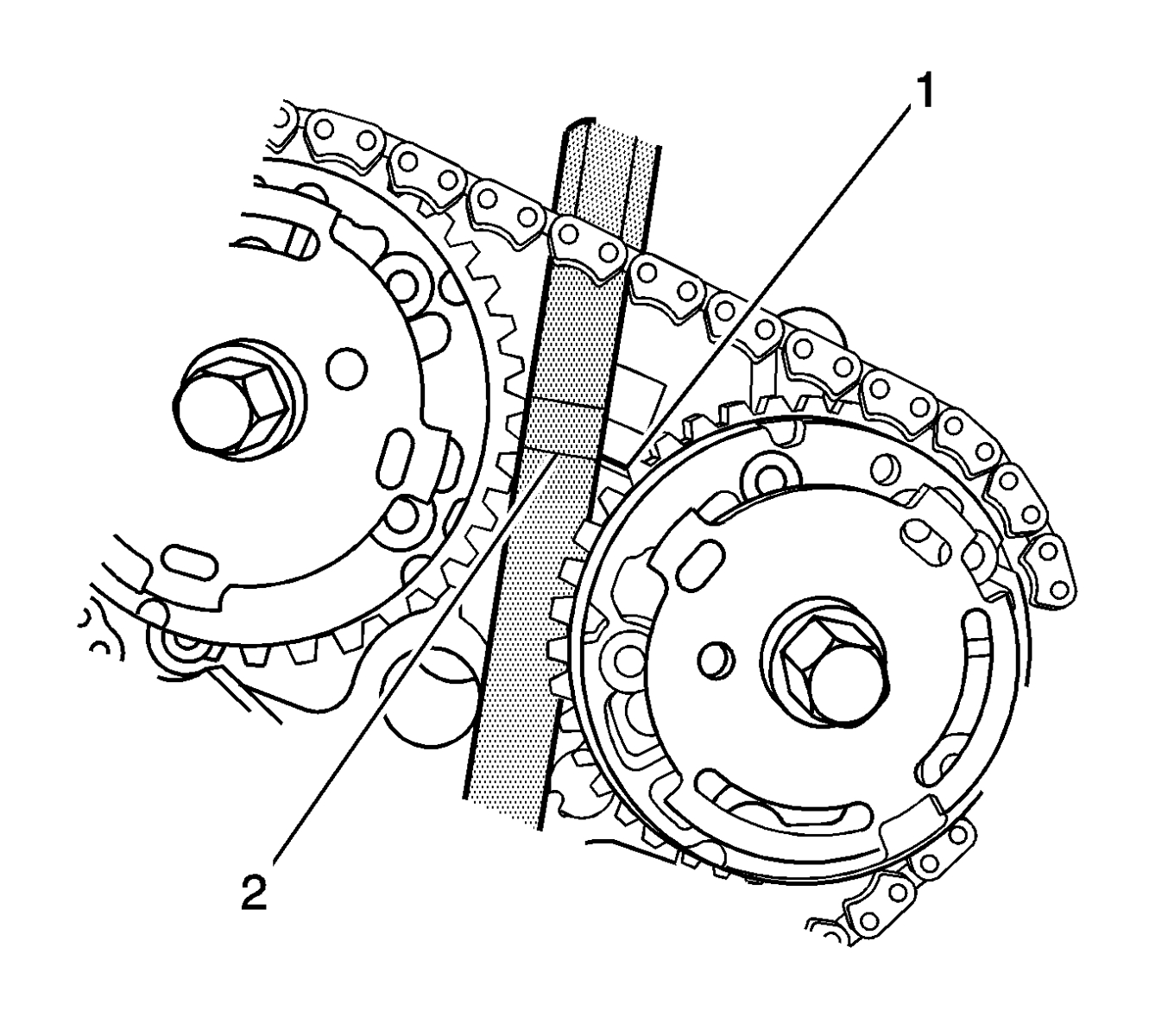

- Insert the Timing Chain Retention Tool between the camshaft actuators, rearward of the timing chain until the bottom line that is scribed in the body of the tool (2) is adjacent to the top surface of the cylinder head (1). This is the approximate installed position.

Important: The engine front cover is removed for clarity in the following graphics, but NOT required to perform the procedure.

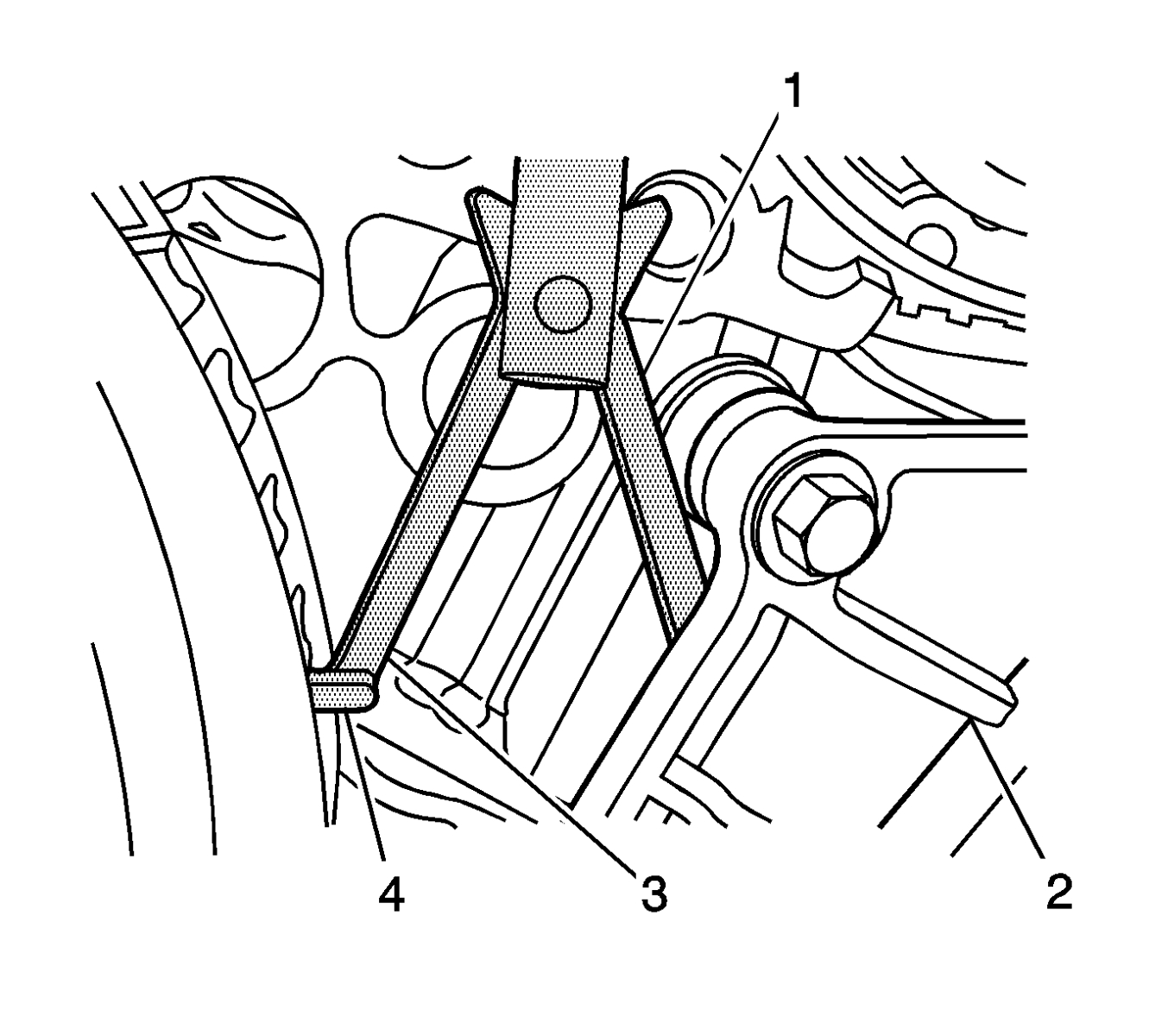

- Ensure that the feet (4) on the legs of the tool are facing the front of the engine.

- Partially expand the legs (1, 3) of the Timing Chain Retention Tool by turning the T-shaped handle clockwise.

- Insert the leg of the tool (1) behind the timing chain guide (2).

- Continue expanding the Timing Chain Retention Tool until the legs (1, 3) contact the timing chain. Do not tighten at this time.

Important: Ensure that the foot (1) of the Timing Chain Retention Tool is engaged into one of the link pockets to prevent tool slippage during tightening of the Timing Chain Retention Tool.

- Hand tighten the Timing Chain Retention Tool. If installed correctly, there should be a small amount of slack in the timing chain between the camshaft position actuator sprockets.

- The Timing Chain Retention Tool is now properly installed to hold the timing chain in position.

Tip: It is not necessary to completely remove the camshaft actuator from the engine in order to install the thrust washers.

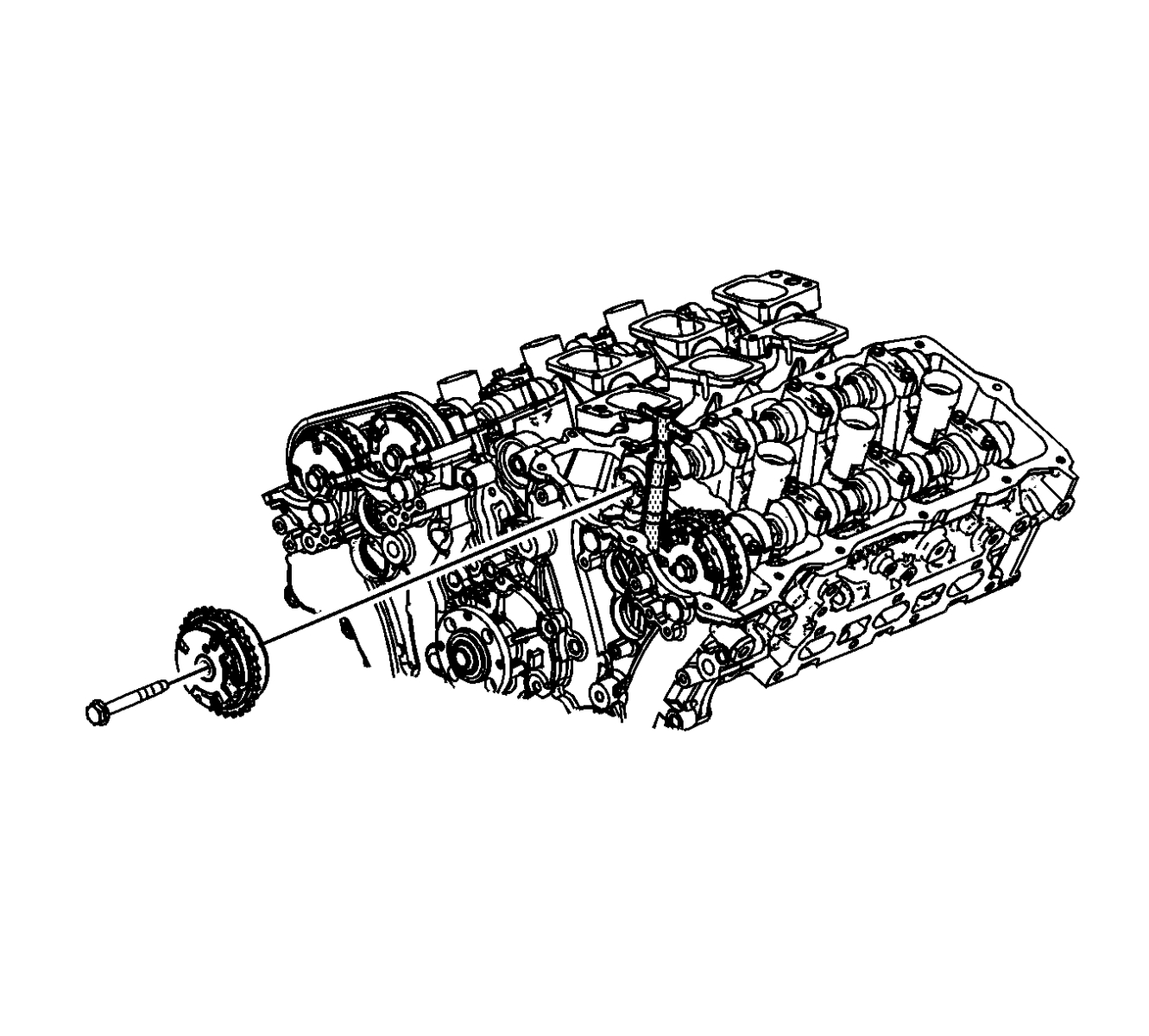

- Remove the intake camshaft position actuator bolt.

- Move the camshaft position actuator forward enough to slip the camshaft thrust washer over the front of the intake camshaft and position it against the cylinder head.

- Position the intake camshaft actuator to the camshaft and install the actuator bolt hand tight. If necessary, slightly rotate the camshaft to engage the timing pin.

- Remove the exhaust camshaft position actuator bolt.

- Move the camshaft position actuator forward enough to slip the camshaft thrust washer over the front of the exhaust camshaft and position it against the cylinder head.

- Position the exhaust camshaft actuator to the camshaft and install the actuator bolt hand tight. If necessary, slightly rotate the camshaft to engage the timing pin.

- Remove the Timing Chain Retention Tool EN-48313.

- Tighten the intake and exhaust camshaft position actuator bolts. Use an open end wrench on the hex cast into the camshaft in order to prevent engine rotation when tightening the camshaft position actuator bolts. Verify that the paint marks on the timing chain and camshaft position actuators are aligned.

Tighten

Tighten the bolts to 58 Nm (43 lb ft). - Install the intake and exhaust camshaft position actuator solenoid valves and bolts.

Tighten

TightenTighten the bolts to 10 Nm (89 lb in). - Install the intake and exhaust camshaft position sensors and bolts.

Tighten

TightenTighten the bolts to 10 Nm (89 lb in). - Connect the engine wiring harness electrical connectors to the intake and exhaust camshaft position (CMP) sensors and actuator solenoid valves.

Parts Information

Please check your part catalog for the cylinder head replacement part number and order accordingly, based on the year, model and applications.

| Part Number | Description |

| 12630941 |

Washer, Camshaft Thrust

(2 required per head) |

| (Aisin Actuator 5 Screw Design) | |

| 12632859 |

|

| (Delphi Actuator 4 Screw Design) | |

| 12609249 | Camshaft Assembly, Exhaust (Left) |

| (LY7 High Output Enclave, Acadia, Traverse, OUTLOOK, ) | |

| 12609250 | Camshaft Assembly, Intake (Left) |

| (LY7 High Output Enclave, Acadia, Traverse, OUTLOOK) | |

| 12604375 | Camshaft Assembly, Exhaust (Right) |

| (LY7 High Output Enclave, Acadia, Traverse, OUTLOOK) | |

| 12609252 | Camshaft Assembly, Intake (Right) |

| (LY7 High Output Enclave, Acadia, Traverse, OUTLOOK) | |

| 11518863 |

Cylinder Head Bolt

(8 required per head) |

| 12591003 |

Fuel Injection Fuel Rail Crossover Tube |

| (LLT Only) | |

| 12591197 |

Fuel Feed Intermediate Pipe |

| (LLT Only) |

Important: When ordering the cylinder head gasket for cylinder head replacement, the kit does not include the M11 head bolts or exhaust manifold gaskets, which will need to be ordered separately.

For part numbers and usage of necessary gaskets, refer to Group 00 6-Cylinder Engine of the appropriate Parts Catalog. Saturn Retailers should refer to the appropriate Parts & Illustration Catalog for the vehicle.

Warranty Information (Thrust Washer Installation) (Buick LaCrosse/Allure)

For vehicles repaired under warranty, use:

| Labor Operation | Description | Labor Time |

| J7534* | Check Camshaft End Play Right Bank | 1.8 hrs** |

| Add | To Install Thrust Washer Right Bank | 0.4 hr |

| J7535* | Check Camshaft End Play Left Bank | 2.4 hrs** |

| Add | To Install Thrust Washer Left Bank | 0.4 hr |

| J7536* | Check Camshaft End Play Both Banks | 3.0 hrs** |

| Add | To Install Thrust Washer Both Banks | 0.8 hr |

| *This is a unique Labor Operation for Bulletin use only. It will not be published in the Labor Time Guide.

**This time includes R&R cam cover. |

||

Warranty Information (Cylinder Head Replacement) (Buick LaCrosse/Allure)

For vehicles repaired under warranty, use:

| Labor Operation | Description | Labor Time |

| J7528* | Check Camshaft End Play Right Bank | 1.8 hrs** |

| Add | To Replace Complete Cylinder Head Assembly Right Bank | 5.5 hrs |

| J7529* | Check Camshaft End Play Left Bank | 2.4 hrs** |

| Add | To Replace Complete Cylinder Head Assembly Left Bank | 6.9 hrs |

| J7530* | Check Camshaft End Play Both Banks | 3.0 hrs** |

| Add | To Replace Complete Cylinder Head Assembly Both Banks | 7.6 hrs |

| *This is a unique Labor Operation for Bulletin use only. It will not be published in the Labor Time Guide.

**This time includes R&R cam cover. |

||

Warranty Information (Thrust Washer Installation) (Cadillac CTS/SRX/STS, Pontiac G8)

For vehicles repaired under warranty, use:

| Labor Operation | Description | Labor Time |

| J7534* | Check Camshaft End Play Right Bank | 2.0 hrs** |

| Add | To Install Thrust Washer Right Bank | 0.4 hr |

| J7535* | Check Camshaft End Play Left Bank | 2.0 hrs** |

| Add | To Install Thrust Washer Left Bank | 0.4 hr |

| J7536* | Check Camshaft End Play Both Banks | 2.4 hrs** |

| Add | To Install Thrust Washer Both Banks | 0.8 hr |

| *This is a unique Labor Operation for Bulletin use only. It will not be published in the Labor Time Guide.

**This time includes R&R cam cover. |

||

Warranty Information (Cylinder Head Replacement) (Cadillac CTS/SRX/STS, Pontiac G8)

For vehicles repaired under warranty, use:

| Labor Operation | Description | Labor Time |

| J7528* | Check Camshaft End Play Right Bank | 2.0 hrs** |

| Add | To Replace Complete Cylinder Head Assembly Right Bank | 7.4 hrs |

| J7529* | Check Camshaft End Play Left Bank | 2.0 hrs** |

| Add | To Replace Complete Cylinder Head Assembly Left Bank | 7.9 hrs |

| J7530* | Check Camshaft End Play Both Banks | 2.4 hrs** |

| Add | To Replace Complete Cylinder Head Assembly Both Banks | 8.2 hrs |

| *This is a unique Labor Operation for Bulletin use only. It will not be published in the Labor Time Guide.

**This time includes R&R cam cover. |

||

Warranty Information (Thrust Washer Installation) (Chevrolet Equinox, Pontiac Torrent)

For vehicles repaired under warranty, use:

| Labor Operation | Description | Labor Time |

| J7534* | Check Camshaft End Play Right Bank | 1.4 hrs** |

| Add | To Install Thrust Washer Right Bank | 0.4 hr |

| J7535* | Check Camshaft End Play Left Bank | 1.1 hrs** |

| Add | To Install Thrust Washer Left Bank | 0.4 hr |

| J7536* | Check Camshaft End Play Both Banks | 1.7 hrs** |

| Add | To Install Thrust Washer Both Banks | 0.8 hr |

| *This is a unique Labor Operation for Bulletin use only. It will not be published in the Labor Time Guide.

**This time includes R&R cam cover. |

||

Warranty Information (Cylinder Head Replacement) (Chevrolet Equinox, Pontiac Torrent)

For vehicles repaired under warranty, use:

| Labor Operation | Description | Labor Time |

| J7528* | Check Camshaft End Play Right Bank | 1.4 hrs** |

| Add | To Replace Complete Cylinder Head Assembly Right Bank | 5.1 hrs |

| J7529* | Check Camshaft End Play Left Bank | 1.1 hrs** |

| Add | To Replace Complete Cylinder Head Assembly Left Bank | 5.2 hrs |

| J7530* | Check Camshaft End Play Both Banks | 1.7 hrs** |

| Add | To Replace Complete Cylinder Head Assembly Both Banks | 5.5 hrs |

| *This is a unique Labor Operation for Bulletin use only. It will not be published in the Labor Time Guide.

**This time includes R&R cam cover. |

||

Warranty Information (Thrust Washer Installation) (Chevrolet Malibu, Pontiac G6, Saturn AURA)

For vehicles repaired under warranty, use:

| Labor Operation | Description | Labor Time |

| J7534* | Check Camshaft End Play Right Bank | 2.1 hrs** |

| Add | To Install Thrust Washer Right Bank | 0.4 hr |

| J7535* | Check Camshaft End Play Left Bank | 1.3 hrs** |

| Add | To Install Thrust Washer Left Bank | 0.4 hr |

| J7536* | Check Camshaft End Play Both Banks | 2.3 hrs** |

| Add | To Install Thrust Washer Both Banks | 0.8 hr |

| *This is a unique Labor Operation for Bulletin use only. It will not be published in the Labor Time Guide.

**This time includes R&R cam cover. |

||

Warranty Information (Cylinder Head Replacement) (Chevrolet Malibu, Pontiac G6, Saturn AURA)

For vehicles repaired under warranty, use:

| Labor Operation | Description | Labor Time |

| J7528* | Check Camshaft End Play Right Bank | 2.1 hrs** |

| Add | To Replace Complete Cylinder Head Assembly Right Bank | 5.1 hrs |

| J7529* | Check Camshaft End Play Left Bank | 1.3 hrs** |

| Add | To Replace Complete Cylinder Head Assembly Left Bank | 5.2 hrs |

| J7530* | Check Camshaft End Play Both Banks | 2.3 hrs** |

| Add | To Replace Complete Cylinder Head Assembly Both Banks | 5.5 hrs |

| *This is a unique Labor Operation for Bulletin use only. It will not be published in the Labor Time Guide.

**This time includes R&R cam cover. |

||

Warranty Information (Thrust Washer Installation) (Buick Enclave, Chevrolet Traverse, GMC Acadia, Saturn OUTLOOK)

For vehicles repaired under warranty, use:

| Labor Operation | Description | Labor Time |

| J7534* | Check Camshaft End Play Right Bank | 2.1 hrs** |

| Add | To Install Thrust Washer Right Bank | 1.6 hrs*** |

| J7535* | Check Camshaft End Play Left Bank | 2.3 hrs** |

| Add | To Install Thrust Washer Left Bank | 1.6 hrs*** |

| J7536* | Check Camshaft End Play Both Banks | 2.6 hrs** |

| Add | To Install Thrust Washer Both Banks | 2.0 hrs*** |

| *This is a unique Labor Operation for Bulletin use only. It will not be published in the Labor Time Guide.

**This time includes R&R cam cover. ***This time includes R&R underhood electrical center and engine mount. |

||

Warranty Information (Cylinder Head Replacement) (Buick Enclave, Chevrolet Traverse, GMC Acadia, Saturn OUTLOOK)

For vehicles repaired under warranty, use:

| Labor Operation | Description | Labor Time |

| J7528* | Check Camshaft End Play Right Bank | 2.1 hrs** |

| Add | To Replace Cylinder Head Right Bank (Includes Build Up and Transfer of Necessary Parts) | 8.6 hrs |

| J7529* | Check Camshaft End Play Left Bank | 2.3 hrs** |

| Add | To Replace Cylinder Head Left Bank (Includes Build Up and Transfer of Necessary Parts) | 8.5 hrs |

| J7530* | Check Camshaft End Play Both Banks | 2.6 hrs** |

| Add | To Replace Cylinder Head Both Banks (Includes Build Up and Transfer of Necessary Parts) | 12.5 hrs |

| *This is a unique Labor Operation for Bulletin use only. It will not be published in the Labor Time Guide.

**This time includes R&R cam cover. |

||

Warranty Information (Thrust Washer Installation) (Saturn VUE)

For vehicles repaired under warranty, use:

| Labor Operation | Description | Labor Time |

| J7534* | Check Camshaft End Play Right Bank | 1.5 hrs** |

| Add | To Install Thrust Washer Right Bank | 1.2 hrs*** |

| J7535* | Check Camshaft End Play Left Bank | 0.8 hr** |

| Add | To Install Thrust Washer Left Bank | 1.2 hrs*** |

| J7536* | Check Camshaft End Play Both Banks | 1.8 hrs** |

| Add | To Install Thrust Washer Both Banks | 1.6 hrs*** |

| *This is a unique Labor Operation for Bulletin use only. It will not be published in the Labor Time Guide.

**This time includes R&R cam cover. ***This time includes R&R engine mount. |

||

Warranty Information (Cylinder Head Replacement) (Saturn VUE)

For vehicles repaired under warranty, use:

| Labor Operation | Description | Labor Time |

| J7528* | Check Camshaft End Play Right Bank | 1.5 hrs** |

| Add | To Replace Complete Cylinder Head Assembly Right Bank | 7.7 hrs |

| J7529* | Check Camshaft End Play Left Bank | 0.8 hr** |

| Add | To Replace Complete Cylinder Head Assembly Left Bank | 7.7 hrs |

| J7530* | Check Camshaft End Play Both Banks | 1.8 hrs** |

| Add | To Replace Complete Cylinder Head Assembly Both Banks | 8.0 hrs |

| *This is a unique Labor Operation for Bulletin use only. It will not be published in the Labor Time Guide.

**This time includes R&R cam cover. |

||

Warranty Information (Thrust Washer Installation) (Chevrolet Camaro)

For vehicles repaired under warranty, use:

| Labor Operation | Description | Labor Time |

| J7534* | Check Camshaft End Play Right Bank | 1.6 hrs** |

| Add | To Install Thrust Washer Right Bank | 0.4 hr |

| J7535* | Check Camshaft End Play Left Bank | 1.6 hrs** |

| Add | To Install Thrust Washer Left Bank | 0.4 hr |

| J7536* | Check Camshaft End Play Both Banks | 2.0 hrs** |

| Add | To Install Thrust Washer Both Banks | 0.8 hr |

| *This is a unique Labor Operation for Bulletin use only. It will not be published in the Labor Time Guide.

**This time includes R&R cam cover. |

||

Warranty Information (Cylinder Head Replacement) (Chevrolet Camaro)

For vehicles repaired under warranty, use:

| Labor Operation | Description | Labor Time |

| J7528* | Check Camshaft End Play Right Bank | 1.6 hrs** |

| Add | To Replace Complete Cylinder Head Assembly Right Bank | 3.4 hrs |

| J7529* | Check Camshaft End Play Left Bank | 1.6 hrs** |

| Add | To Replace Complete Cylinder Head Assembly Left Bank | 4.6 hrs |

| J7530* | Check Camshaft End Play Both Banks | 2.0 hrs** |

| Add | To Replace Complete Cylinder Head Assembly Both Banks | 5.0 hrs |

| *This is a unique Labor Operation for Bulletin use only. It will not be published in the Labor Time Guide.

**This time includes R&R cam cover. |

||

SEOCONTENT-END

Bulletin No.: 08-06-01-011 K

Date: June, 2016

To View or Download this Document Click Here

Loading...

Loading...

| “This site contains affiliate links for which OEMDTC may be compensated” |

- 5W30

- 1 Quart Bottles

- Set of 6

- Full Synthetic Formulation: This pack of 12 bottles contains premium full synthetic motor oil designed for maximum engine protection and performance.

- Viscosity Grade: SAE 5W-30 viscosity for superior cold-start protection and enhanced fuel economy.

- API Certification: Meets the latest API SP resource conserving standards for modern engines.

- Bottle Size: Each bottle contains 1 quart (0.946 liters) of motor oil.

- Brand: Reputable ACDelco brand known for quality automotive products.

- Full synthetic 5W-30 motor oil that is made with natural gas and designed to maximize engine protection

- Formulated for high-performance diesel and gasoline engines in European vehicles, including BMW, Mercedes-Benz, and VW

- Helps extend engine life and protects for up to 15 years or 500,000 miles, whichever comes first, guaranteed*

- Delivers faster low-temperature oil flow and protection in extreme heat

- Protects horsepower and keeps engine closer to factory clean (based on Sequence VH and M-111 sludge test using SAE 0W-40)

- Motul’s expertise addresses specific industrial constraints with high proficiency and innovative solutions.

- Our Passenger Car Product range protects and takes care of your vehicle for the duration of its life cycle.

- From the 8100, our 100% Synthetic oil line of products, to Coolants, Brake fluids, and Transmission lubricants, Motul offers you a wide choice of products to keep your car running.

- Passion is what unites lovers of engineering to their machinery, the same passion that Motul puts into innovation.

- Motul has developed high performance metalworking fluids and lubrication products to address the highly demanding needs from the growing worldwide industrial business world since 1989.

- Leading Manufacturer Of High-Quality Products

- International Renown For Our Diverse Range Of Award-Winning Products

- Fully Equipped With State-Of-The-Art Technology

- All Products Have Been Designed With The Professional In Mind

- Constantly Modernizing Our Powerful Devices To Meet The Demands Of The Modern User

- For best performance, follow the manufacturer's recommendations in your vehicle owner’s manual.

- Advanced full synthetic formula

- Outstanding thermal and oxidation stability

- Enhanced frictional properties

- Excellent low-temperature capabilities

- Designed to help provide protection for your vehicle’s engine

- Licensed to the dexos1 Gen 2 engine oil specification, which is the General Motors

’ OEM engine oil specification

’ OEM engine oil specification - Meets ILSAC GF-5 specifications to fulfill current energy-conserving performance standards

- Meets API SN Service Classification requirements to be suitable for use in modern engines

- Helps protect against high-temperature deposits to reduce engine wear

- Castrol EDGE C3 is a European formulation that is specifically engineered to improve engine durability. It is a full synthetic diesel oil that is suitable for use in automotive diesel engines where the manufacturer requires a 5W-30 oil

- Specifications established by BMW, Mercedes-Benz and Volkswagen demand that oils meet a certain minimum high temperature/high shear (HT/HS) viscosity to provide proper protection

- Diesel Application. Formulated for highly tuned four cylinder and latest technology engines that operate at higher temperatures, such as European Vehicles

- Approved and Licensed Specifications

- API SN/CF , ACEA C3 , BMW Longlife-04 , GM - dexos2 supersedes GM-LL-B-025 & GM-LL-A-025 , MB - Approval 229.31/229.51 , Renault RN 0700/0710 , VW 502 00/505 00/505 01

Last update on 2025-05-08 / Affiliate links / Images from Amazon Product Advertising API

This product presentation was made with AAWP plugin.