| “This site contains affiliate links for which OEMDTC may be compensated” |

NHTSA ID Number: 10126228

Manufacturer Communication Number: PI1376

Summary

This preliminary information provides a procedure to apply grease to the seat track to correct the customer concern of excessive movement and a click noise while driving.

Condition/Concern

Driver and/or passenger seat lower cushion exhibits excessive lateral seat movement combined with a clunk type feeling, or generates a click type noise. This condition occurs when the seat is occupied and the vehicle is being driven on roads with multiple curves or during low speed maneuvers.

This condition may be caused by movement between the seat pan front pivot points and the seat frame pivot bar.

The plastic attachment points may “stick” then “slip” creating the condition. There may also be excessive clearance between the power seat vertical adjuster actuator and the attachment point on the seat frame.

| 13405675 | Front Seat Lateral Retainer | 1 per seat |

| 13594989 | Shim Clip | 1 per seat |

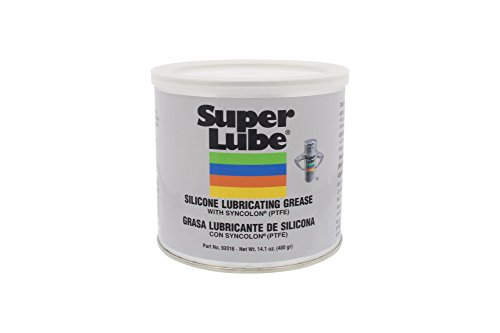

| 12371287 | GM Super Lube 3 oz. Tube – US | As Required |

| 10953437 | GM Super Lube 3 oz. Tube – CA | As Required |

12 Affected Products

Vehicles

| MAKE | MODEL | YEAR |

CADILLAC | ESCALADE | 2015 |

CADILLAC | ESCALADE ESV | 2015 |

| CHEVROLET | SILVERADO 1500 | 2015 |

| CHEVROLET | SILVERADO 2500 | 2015 |

| CHEVROLET | SILVERADO 3500 | 2015 |

| CHEVROLET | SUBURBAN | 2015 |

| CHEVROLET | TAHOE | 2015 |

| GMC | SIERRA 1500 | 2015 |

| GMC | SIERRA 2500 | 2015 |

| GMC | SIERRA 3500 | 2015 |

| GMC | YUKON | 2015 |

| GMC | YUKON XL | 2015 |

1 Associated Document

Manufacturer Communications

Bulletin No.: PI1376

Date: December, 2014

https://www.nhtsa.gov/recalls?nhtsaId=10126228

MC-10126228-9999.pdf 1499.942KB

Loading...

Loading...

NHTSA ID Number: 10072596

Manufacturer Communication Number: PI1376

Summary

SUMMARY TO BE PROVIDED ON A FUTURE DATE.

1 Associated Document

Service Bulletin Document

Bulletin No.: PI1376

Date: December, 2014

https://www.nhtsa.gov/recalls?nhtsaId=10072596

SB-10072596-0335.pdf 1499.942KB

Loading...

Loading...

| “This site contains affiliate links for which OEMDTC may be compensated” |

- Super Lube-21030 Synthetic Multi-Purpose Grease, 3 Oz.

- Auto & Truck Maintenance

- Country of manufacture: United States

- Manufacturer: SUPER LUBE

- Package Dimensions: 18" L x 18" W x 21" H

- Synthetic Oil With Suspended Syncolon (Ptfe) Particles

- It Is Waterproof

- Usda/Nsf Rated H-1

- Reduces Friction And Wear

- Super Lube Oil

- NO DRIP, RUN, OR EVAPORATION – This multi-purpose grease comes in an aerosol form that is safe to use on anything that slides, rolls, swivels or squeaks. It is a synthetic, heavy duty lubricant that provides superior wear protection. It penetrates, lubricates and extends the life of machinery and equipment.

- NSF CERTIFIED FOOD GRADE & CLEAN – Ths product is a NSF registered Food Grade lubricant, rated H1 for incidental food contact. Meets former USDA (H1) guidelines.

- SUPERIOR WEAR PROTECTION – This lubricant transfers a microscopic PTFE film onto the contacting metal surfaces. This transfer film is extremely slippery, with one of the lowest coefficients of friction of any known solid material. It prevents direct metal-to-metal contact and abrasive wear.

- HIGH DIELECTRIC STRENGTH – Exhibits exceptionally high dielectric strength, enabling it to resistantly insulate and prevent arcing or tracking between electrical components operating at high voltages.

- SUPERIOR ANTI-WEAR PROPERTIES – Possess superior anti-wear qualities due to their fortification with specialized anti-wear and extreme pressure additives that create a protective film on metal surfaces, preventing excessive wear even under the high pressures and shock loadings found in hydraulic systems.

- Included Components: Car Care Chemicals; Flushes, Sealers & Lubricants; Greases General Application Greases; Automotive Greases

- The Package Height Of The Product Is 2 Inches

- The Package Length Of The Product Is 9 Inches

- The Package Width Of The Package Is 4 Inches

- NSF registered Food Grade lubricant, rated H1 for incidental food contact. Meets former USDA (H1) guidelines

- High thermal conductivity

- Seals out moisture

- Viscosity & thermally stable

- Will not react with rubber or plastic

- Brand- Superlube

- Description -Synthetic Grease

- Manufacturer's Part Number - 41150

- Package Quantity - 12/Case

- Size - 14 oz. Cartridge

- Patented synthetic NLGI grade 2 heavy-duty, multipurpose lubricant

- Dielectric, Food Grade, Clean

- NSF Rating H-1, safe for incidental food contact

- Will not drip, run or evaporate

- Temperature Range: -45 to 450 F

- NLGI Grade: 2

- Net Volume: 3 oz

- Four Ball Weld Point: 400 kg

- Dropping Point: greater than 500 F

Last update on 2025-05-08 / Affiliate links / Images from Amazon Product Advertising API

This product presentation was made with AAWP plugin.

SEOCONTENT-START

Service Bulletin

File in Section: –

Bulletin No.: PI1376

Date: December, 2014

PRELIMINARY INFORMATION

Subject: Front Seat Lateral Movement and/or Click Type Noise While Driving

Models: 2015 Cadillac Escalade Models

Escalade Models

2015 Chevrolet Silverado, Suburban, Tahoe

2015 GMC Sierra, Yukon Models

Condition/Concern

Some customers may comment that the driver and/or passenger seat lower cushion exhibits excessive lateral seat movement combined with a clunk type feeling, or generates a click type noise. This condition occurs when the seat is occupied and the vehicle is being driven on roads with multiple curves or during low speed maneuvers.

This condition may be caused by movement between the seat pan front pivot points and the seat frame pivot bar.

The plastic attachment points may “stick” then “slip” creating the condition. There may also be excessive clearance between the power seat vertical adjuster actuator and the attachment point on the seat frame.

Recommendation/Instructions

Use the following steps to lubricate the front seat pan pivot points, add a lateral retainer to the outboard pivot, and install a shim clip between the power seat vertical adjuster actuator and the seat frame (if required) to the affected seat(s):

4025118

1. Partially disengage the front seat cushion outer finish cover.

• Only remove the front seat cushion outer finish cover front fastener (1) as show above.

• Disengage the cover by pulling upward near the retainer clip locations.

Caution: The front seat cushion outer finish cover rear fastener is still installed, take caution when disengaging the cover.

4025189

2. Partially remove the forward half of the lower seat cushion cover and pad on the affected seat.

Note: It is NOT necessary to completely remove the seat cover and pad, only the side and front retainers need to be released. The rear of the cover can remain attached.

• Move the seat into a position where the front and inboard side of the seat cover can be accessed.

• Disengage the front, left and right J-channel retainers from the seat cushion frame as shown above.

4024923

3. Remove the four screws that attach to the two pivot blocks to the seat pan.

Note: Lift the seat pan to provide additional working access.

3967501

4. Slide the two pivot blocks to the center of the seat to allow for applying grease to the pivot bar.

Important: DO NOT attempt to remove the pivot blocks from the seat. Possible damage to the pivot blocks may result.

3619960

5. Using a small brush, apply GM Super Lube, GM P/N 12371287 (In Canada, use 10953437) as shown. Ensure the complete contact surface is coated.

4025748

6. Move the pivot blocks back out to their original position.

3619963

7. Align the holes in the seat pan with the holes in the pivot blocks.

3619964

8. Hand start the four screws; Do NOT tighten.

4031854

9. Install the lateral retainer to the outboard end of the pivot bar as shown above. Ensure the retainer is fully seated around the pivot bar and to the pivot block.

Note: The lateral retainer can only be installed one way.

• The double slotted side (1) of the lateral retainer attaches to the pivot block.

• The single slotted side (2) of the lateral retainer attaches to the end of the pivot bar.

4031857

4032701

10. Install a nylon tie strap around the retainer as shown above. Trim the excess tie strap material.

11. Tighten the four screws for the pivot blocks.

12. Wipe off any excess lubricant.

13. Re-install the forward portion of the lower seat cushion cover on the affected seat. Ensure all side and front retainers are fully engaged to the seat frame.

4031883

3619968

14. Locate the power seat vertical adjuster actuator attachment to the seat frame.

15. Inspect for the presence of the shim clip (1) as shown.

16. If a shim clip is not present, install the shim clip (1) as shown.

Note: It may be necessary to slightly spread the bracket on the seat frame with a large screwdriver to allow clearance for the clip.

Parts Information

Part Number Description Qty

13405675 Front Seat Lateral Retainer 1 per seat

13594989 Shim Clip 1 per seat

12371287

(In Canada, use 10953437)

GM Super Lube 3 oz. Tube As Required

Warranty Information

For vehicles repaired under the Bumper-to-Bumper coverage (Canada Base Warranty coverage), use the following labor operation. Reference the Applicable Warranties section of Investigate Vehicle History (IVH) for coverage information.

Labor Operation Description Labor Time

7080188* Lubricate Front Seat Pivot Points, Install Lateral Retainer and Install Seat Actuator Shim Clip.

0.6 hr

Add Perform procedure to both front seats (If Needed) 0.4 hr

*This is a unique Labor Operation for Bulletin use only. It will not be published in the Labor Time Guide.

SEOCONTENT-END