| “This site contains affiliate links for which OEMDTC may be compensated” |

NHTSA ID Number: 10165125

Manufacturer Communication Number: 100310001E

Summary

This informational bulletin provides information on Wheel Balancer Mounting Instructions.

28 Affected Products

Vehicles

| CHEVROLET | SILVERADO | 2017 |

| CHEVROLET | SILVERADO 1500 | 2011 |

| CHEVROLET | SILVERADO 2500 | 2011-2016, 2018-2020 |

| CHEVROLET | SILVERADO 3500 | 2013 |

| GMC | SIERRA | 2017 |

| GMC | SIERRA 2500 | 2011-2016, 2018-2020 |

| GMC | SIERRA DENALI | 2011-2013, 2015-2016, 2018 |

SEOCONTENT-START

Bulletin No.: 10-03-10-001E

Date: September, 2019

| Subject: | Revised Wheel Balancer Mounting Instructions (Heavy Duty Models Only) |

| Models: | 2011-2020 Chevrolet Silverado 2500HD-3500HD |

| 2011-2020 GMC Sierra 2500HD-3500HD | |

| Attention: | This Bulletin also applies to any of the above models that may be Middle East and Israel export vehicles. |

This Bulletin has been revised to add 2018 – 2020 Model Years. Please discard Corporate Bulletin Number 10-03-10-001D.

Revised Wheel Balancing Procedure for Consistent Balancing Results

Concern

Customers may comment on a vibration or tire balance concern while driving, usually at higher speeds. Initial attempts at balancing the tire and wheel assemblies may not have not resolved the condition.

Note: All current Service Information, appropriate Service Bulletins and PIs still apply to this condition. Specific details related to the Silverado and Sierra HD trucks are included in this bulletin to assist with tire vibration concerns.

The 2011-2017 tire and wheel assemblies for the heavy duty (HD) trucks, especially the dual rear wheel (dually), have more mass and a larger overall diameter requiring specialized equipment and care.

GM Dealer Equipment

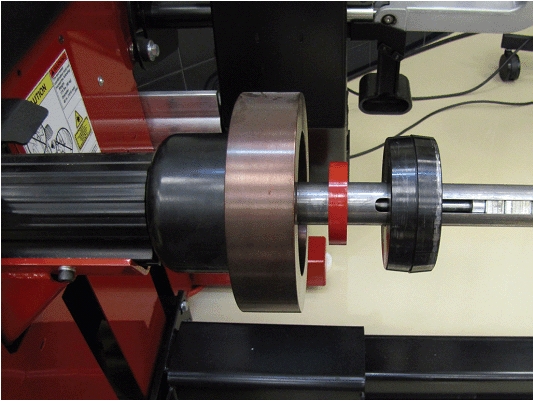

GM Dealer equipment MD Collet Kit 20–3116–1 is the best device for HD wheel balancing and Radial Force Variation (RFV) measurement using the Hunter GSP9700.

Dual Rear Wheels (DRW)

The following information is specific to the Dual Rear Wheel (DRW) Trucks

- Various adapters are listed below for use with the DRW trucks. The first tool listed is the preferred tool and will provide the best/most consistent results.

- Preferred adapter/process

- There is a new adapter released for use with the DRW trucks (and also works well with the single rear wheel trucks). This kit is available through GM Dealer Equipment (in Canada, at DES-Canada) and works with the Hunter 9700 balancer.

- The kit fits Aluminum DRW wheels and allows the normal functionality of the road force variation balance procedure. For steel wheels it will work better than any other adapter, but the repeatability test referenced below may still be required, and may have a tight fit.

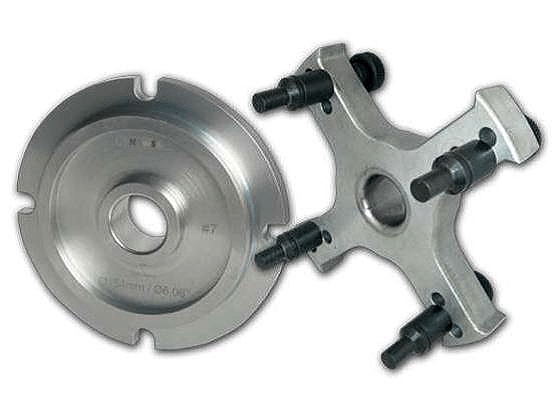

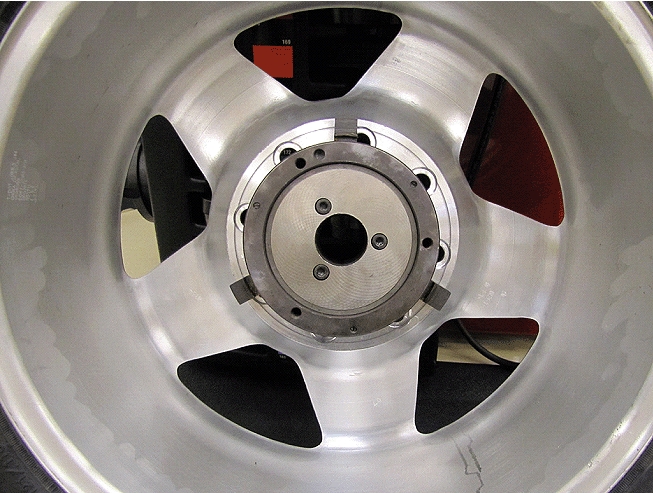

Haweka Pro Max GM II Kit for 8×180 and 8×210 Vehicles

Haweka Pro Max Adapter Installed

- The remaining available cones/adapters may not produce repeatable balancing results with some balancers. With the older tools available, it will most likely not be possible to pass a centering check when attempting to balance assemblies. If the updated tools released are not used, it may be necessary to balance the tire/wheel assembly bypassing the centering check on the Hunter 9700 (and similar) equipment or by using a truck-type balancer that is capable of handling larger assemblies similar to medium duty truck wheels (Comparable to the TopKick or Kodiak trucks).

- The information provided below is not absolute, it is only provided as guidelines to assist with balancing the tire/wheel assemblies. This specific procedure does not need to be used, but any procedure used must provide repeatable results.

-

- For DRW trucks ONLY, the new adapters are available that will allow the tire/aluminum wheel assembly to reliably pass the centering check on the Hunter 9700 balancer (item #709-280 400 113 Haweka Pro Max GM II Kit for 8×180 and 8×210 vehicles) If this adapter is not available, use the most appropriate adaptors, such as item #20-1207-1 Extra Large Truck Cone Kit that contains: Wheel Spacer #46-309-2; Extra Large Truck Cone #192-92-2. (see photos below)

- When using truck wheel balancers, it is important to use the proper settings on the machine for the appropriate assembly to get within +/- 0.5 oz (15 g) maximum balance tolerance. Typical modes are truck, RV or car. Refer to your balancers instruction manual for proper settings.

Note: The following is a procedure that can be used on the Hunter 9700 equipment. Other equipment can be used, but repeatable results must be obtained.

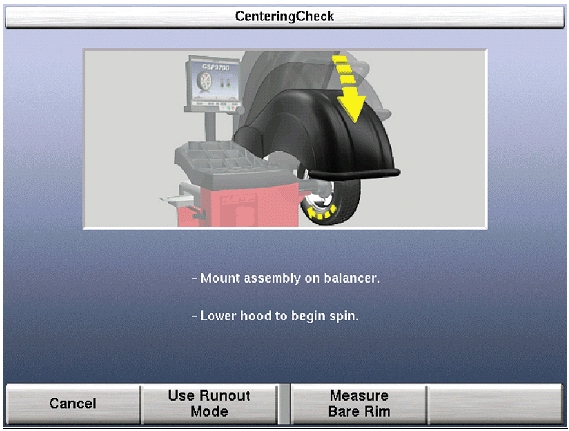

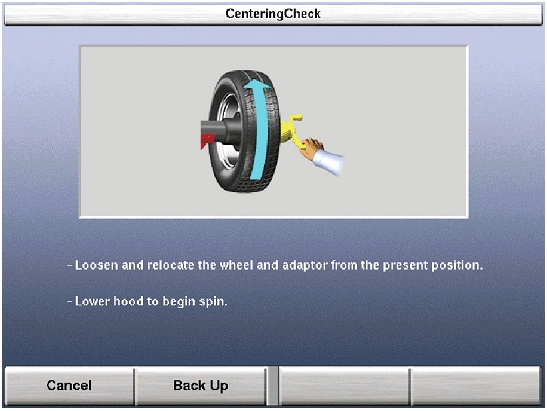

Perform a Balance Mode CenteringCheck

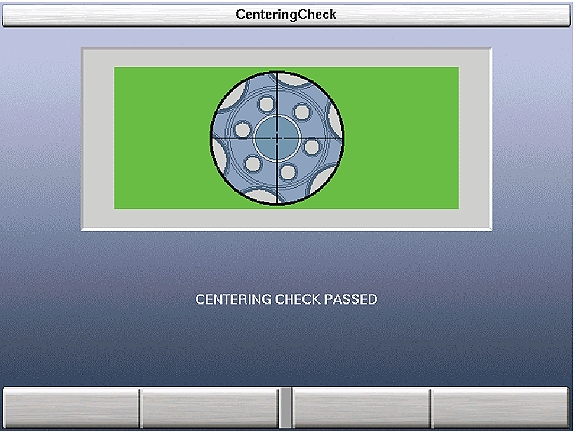

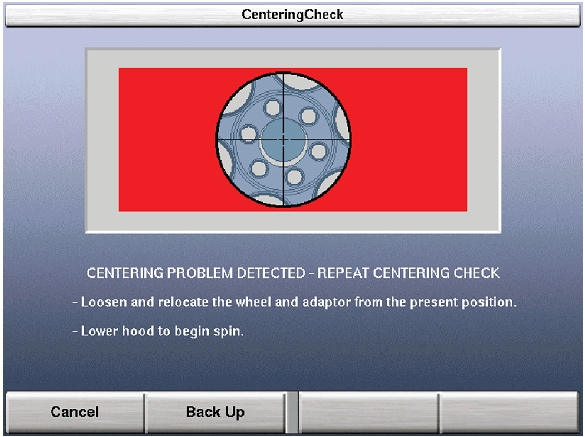

- If the wheel successfully passes the CenteringCheck, balancing procedures can be performed. If the wheel does not pass the CenteringCheck, “test spins” may be performed to check for wheel centering repeatability.

- From the balance screen, press the “Perform CenterCheck” softkey.

- Mount the wheel on the spindle and secure with the wing nut/ AutoClamp.

- If the rim runout method is selected, press “Use Balance Mode.”

- Lower the hood and spin the wheel.

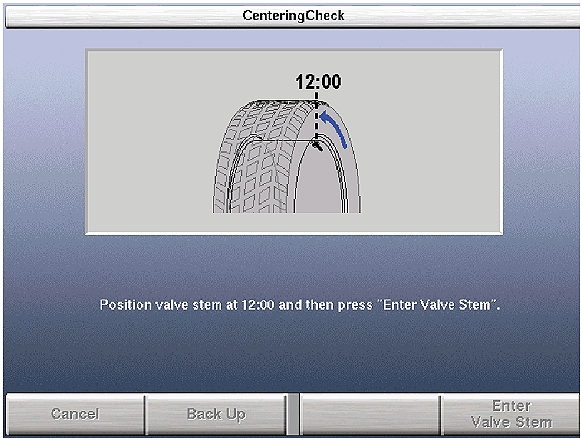

- When spin is complete, raise the hood to position the wheel with the valve stem at 12:00 o’clock and then press “Enter Valve Stem” softkey.

- Loosen the wing nut / AutoClamp. Remove the wheel from the collet and rotate wheel position on the spindle to change valve stem location. Re-install the wheel on the collet and re-clamp.

- Lower the hood and the wheel will spin.

- When spin is complete, raise the hood and position the wheel with valve stem at 12:00 o’clock and then press “Enter Valve Stem” softkey.

- CenteringCheck results will appear.

- If CenteringCheck is successful, balancing procedures can be performed. If the wheel does not pass the CenteringCheck, perform test spins as described below.

- If using the new item #709-280 400 113 Haweka Pro Max GM II Kit for 8×180 and 8×210 vehicles, it is still possible to get a failed centering check. Re-mount the assembly and try again. Steel wheels may still not pass and may require the procedure detailed below in the “Perform a Balance Mode CenteringCheck.”

Performing Centering Repeatability Test Spins

- Once failing a CenteringCheck after the wheel assembly has been mounted, and the correct Balancer Setup is in place, test spins can be performed. The procedure for checking centering accuracy is as follows:

Notice: It may be necessary to disable the load roller if balance results are considerably inconsistent, in order to obtain better balance results of the wheel. However this will leave Radial Force Variation (RFV) ratings as unknown and may be the root cause of a vibration concern.

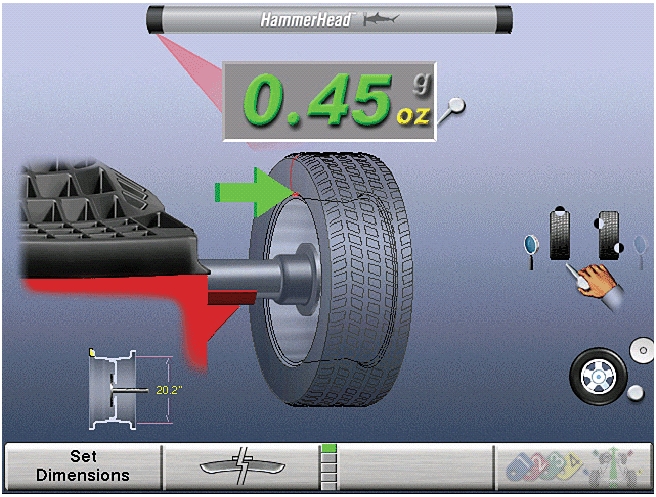

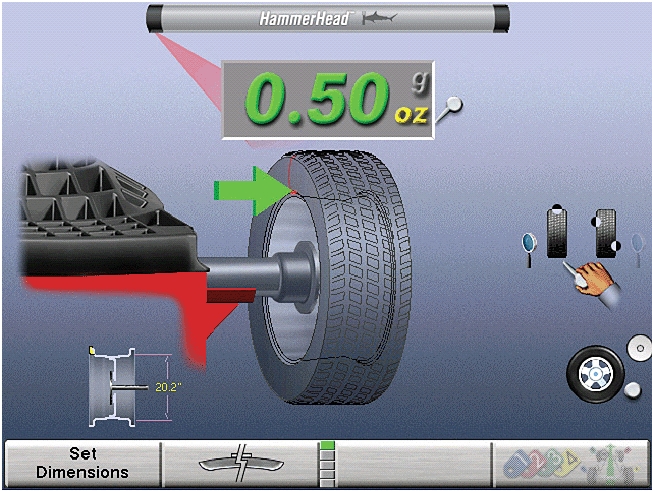

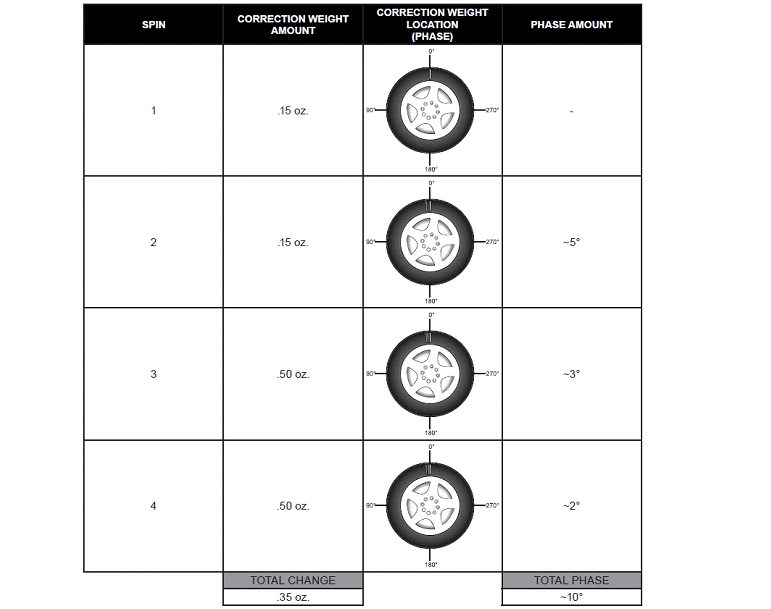

- Perform a spin. Record the needed correction weight and mark the correction weight location on the tire with a tire pencil. This will be recorded as “Spin 1.”

- Unclamp the wheel assembly and change its position by 90 degrees, either clockwise or counterclockwise. Throughout the procedure, continue the positioning using the clock motion first used (i.e. all clockwise or all counterclockwise).

- Perform a spin. Record the needed correction weight and mark the correction weight location on the tire with a tire pencil. This will be recorded as “Spin 2.”

Evaluate Results:

When the two test spins have been completed, the centering repeatability results may be evaluated.

Acceptable Results:

- If correction weight amounts and correction weight locations remain relatively consistent, the results can be considered valid.

- The following sample shows an acceptable result, but only 2 samples are needed.

- If correction weight amount varies more than 0.9 oz., or if phase varies by more than 135° then current balancer operating condition and/or setup is unacceptable and should be evaluated.

- Conditions that can cause unacceptable results include:

- Incorrect Balancer Settings

- Worn Spindle Shaft

- Worn Collets / Cones

Radial Force Variation (RFV)

- When attempting to obtain the best possible RFV measurements for a tire/wheel assembly that does not pass the CenteringCheck®, it is necessary to re-analyze RFV measurements to verify repeatable results.

- Obtain initial RFV measurement and record the result.

- Press the “Show Runout & Force Matching” softkey.

- Then press the “Runout/Matching” softkey and follow procedure listed on the screen.

- Mark the high point of tire and low point of wheel assembly as indicated by the balancer. Match Mount the assembly by removing tire and remounting it so the two markings meet, while exercising the bead to verify it is set properly.

- Remove the tire/wheel assembly and remount it on the balance tool in a different position.

- Re-analyze the corrected tire/wheel assembly to verify repeatable results.

- The locations of the high point of RFV and balance weight locations should be within +- 135.°

- The balance weight should be +- 0.9 oz.

Single Rear Wheel Trucks

- Hunter Equipment has developed a bulletin specifically to assist with balancing single rear wheel assemblies. That information is duplicated below with the permission of the Hunter Corporation.

- For balancing the tire/wheel assembly, make sure to use one of the following three methods to mount the assembly. Using one of these methods should allow the tire/wheel assembly to repeatedly pass the centering check and allow for good RFV and balancing measurements:

Method 1a: Preferred Method 1

- Securing the offset spacer, 46-653-2 or 46-433-2, to the spindle hub face. Mount the spacer, 46-360-2 and collet, 192-174-2 (4.800”-5.025” / 122 mm -128 mm), on the spindle shaft.

- Center the tire/wheel assembly bore on the collet and clamp using the 6 inch clamping cup or 9 inch alloy clamping cup.

Alloy Wheel: 6 inch Clamping Cup w/AutoClamp

Steel Wheel: 6 inch Clamping Cup w/Wing Nut

Method 1.b: Preferred Method 2

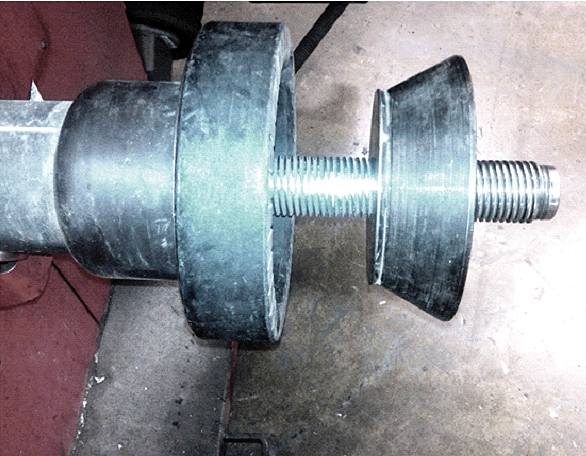

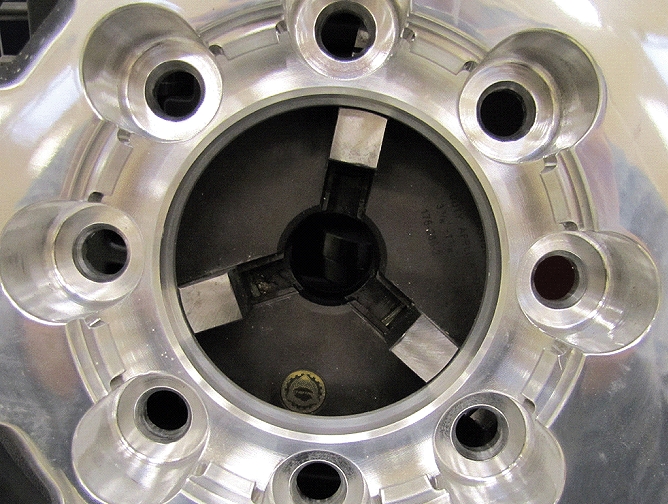

Securing the dual-sided collet from item #709-280 400 113 Haweka Pro Max GM II Kit for 8×180 and 8×210 vehicles to the spindle hub face. Mount the wheel and then the four-arm star on the spindle shaft and tighten with the auto clamp or wing nut.

Dual Sided Collet Mounted on the Back of a Single Wheel Aluminum Rim

Four Arm Star Mounted to the Front of a Single Wheel Aluminum Rim

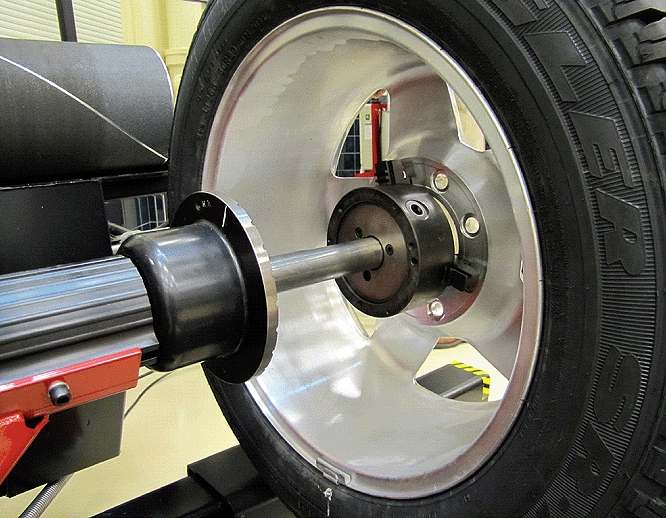

Method 2: Alternate Method (Hunter TruckChuck)

-

- Secure the Hunter TruckChuck, 20-1602-1, to the center bore of the rim. Ensure the chuck is secure and uniformly attached.

Hunter TruckChuck Correctly Attached (Rear View)

Hunter TruckChuck Correctly Attached (Front View)

Hunter TruckChuck Correctly Attached (Close Up)

- Clamp using the 6 inch clamping cup or 9 inch alloy clamping cup.

After mounting the tire/wheel assembly to the balancer, proceed with the balance/RFV operations verifying repeatable results.

SEOCONTENT-END

Bulletin No.: 10-03-10-001E

Date: September, 2019

To View or Download this Document Click Here

Loading...

Loading...

Bulletin No.: 10-03-10-001D

Date: May-2017

To View or Download this Document Click Here

Loading...

Loading...

Bulletin No.: 10-03-10-001C

Date: October, 2014

To View or Download this Document Click Here

Loading...

Loading...

Bulletin No.: 10-03-10-001B

Date: Jun-2013

To View or Download this Document Click Here

Loading...

Loading...

Bulletin No.: 10-03-10-001B

Date: June, 2013

To View or Download this Document Click Here

Loading...

Loading...

Bulletin No.: 10-03-10-001A

Date: Oct-2012

To View or Download this Document Click Here

Loading...

Loading...

Bulletin No.: 10-03-10-001A

Date: October, 2012

To View or Download this Document Click Here

Loading...

Loading...

Bulletin No.: 10-03-10-001A

Date: October, 2012

To View or Download this Document Click Here

Loading...

Loading...

| “This site contains affiliate links for which OEMDTC may be compensated” |

- Superior Quality – High-quality material is guaranteed; close tolerances ensure the weight of the products is accurate.

- Anti-Corrosion – The surface layer of the wheel weights is first electro-galvanized, then subjected to a multilayer and omni-dimensional plastic spraying process.

- Eco-Friendly – The material of the products is lead-free and universal for all 50 states.

- U.S White Tape– U.S.-made Four-Season Tape ensures perfect sticking results, with wide paper backing designed for easy peeling.

- Specification – 1 segment: 1 oz; 1 strip: 4 segments; 1 box: 18 strips. In total: 1 box = 18 strips = 72 segments = 72 oz.

- MC type For alloy wheels of Ford

, Chrysler, GM van and light truck

, Chrysler, GM van and light truck - Eco friendly, 50 state legal, zinc coated Steel tape weights

- Grey 80pcs/kit: 1/4oz, 1/2oz, 3/4oz, 1oz 15pcs each, 1 1/4oz, 1 1/2oz, 2oz and 2 1/2oz 5pcs each

- High zinc micron + epoxy double paint coating makes the best rust prevention possible

- Suction film packaging to prevent and reduce delivery damage

- Superior Quality – High-quality material is guaranteed; close tolerances ensure the weight of the products is accurate.

- Anti-Corrosion – The surface layer of the wheel weights is first electrogalvanized, then a multilayer and omnidirectional plastic spraying process is applied.

- Eco-Friendly – The material of the products is lead-free and suitable for all 50 states.

- U.S. White Tape – U.S.-made Four-Season Tape provides perfect sticking results, with wide paper backing designed for easy peeling.

- Specification – 1 segment: 1/4 oz; 1 strip: 8 segments; 1 box: 6 strips. In total: 1 box = 6 strips = 48 segments = 12 oz.

- Superior Quality – High-quality material is guaranteed; close tolerances ensure the weight of the products is accurate.

- Anti-Corrosion – The surface layer of the wheel weights is first electro-galvanized, then subjected to a multilayer and omni-dimensional plastic spraying process.

- Eco-Friendly – The material of the products is lead-free and universal for all 50 states.

- U.S White Tape – U.S.-made Four-Season Tape ensures perfect sticking results, with wide paper backing designed for easy peeling.

- Specification – 1 segment: 1 segment: 1/4 oz; 1 strip: 715 segments; In total: 1 box = 1 strip = 715 segments = 178 oz

- Used for balancing all types of steel wheels. Suitable for passenger cars, light trucks, SUVs, vans, and full-size pickups.

- Hardened spring steel clips improve weight retention; easy to install and designed for a correct fit.

- CKAuto balance weights keep your wheels in dynamic balance under high-speed rotation.

- Lead wheel weights provide a safe tire system and safe driving, meeting U.S. standards with high quality guaranteed.

- Specification: P type, 0.25 oz, 0.5 oz, 0.75 oz, 1 oz; 25 pcs for each style, totaling 100 pcs.

- SPECIFICATIONS - 1/4oz Segments. 8 Segments per Strip. 6 Strips in total. Total Weight = 12 oz (0.75lbs) Eco-Friendly – The material of the products is lead-free, universal for 50 states

- PREMIUM QUALITY- Lead free 1/4oz wheel weights with adhesive backing, Easy to peel off, solid load, will not fall off under extreme conditions; High quality material is garanteed, close tolerance make sure the weight of the products are accurate

- ANTI-CORROSION - The surface of the product is treated with galvanized layer to prevent corrosion and rust, and has sufficient flexibility. It is suitable for any wheel shape and size; Perfect for wheel balancing, drapery curtain weights, truck and SUV wheels, as well as other hobbies and crafts

- MULTIFUNCTIONAL - JiiinMiiin High quality tape to ensure secure adhesion,Low profile for best fitment and a great aesthetic look,Eco friendly, powder coated Steel tape weights. Designed segments allows for easier contouring to the wheel shape when installing, Perfect for Cars, Trucks, SUVs

- WARRANTY - If the product has any quality problem, you can contact us at any time, We will reply you within 24 hours, making every of our customer get right good products is our mission - We know that we still have room for improvement, so when you are not satisfied with our products, we sincerely hope you could leave us a message, give us a chance to improve,thank you

- Specifications: 5kg gray adhesive stick on roll wheel weights, 1/4oz Segments.Total segments:715pcs,Total Weight = 175 oz(11lbs/5kg). Precision segments perform an accurate balance

- Strong Adhesion: With strong sticky, EZISOE stick on wheel weights can be firmly adhered to your wheels and won't fall off easily.

- High quality for durability: The balance are treated with a powder coating to prevent corrosion and rust, and can withstand any weather conditions your car normally experiences. Meanwhile, our wheel weights feature rounded corner stamping to easily contouring any wheel shape and size

- Widely Used: The lead-free wheel weights can bring you a safe and balanced driving experience, fit for cars, trucks, SUVs, motorcycle wheels as well as some ATVs, UTVs. Also can be used for hobbies and handicrafts.

- Sincere after-sales service: we provide you with one year warranty. If you have any questions about the product, please feel free to contact us. We will give every customer a satisfactory answer.

- Superior Quality – High quality material is guaranteed, close tolerance make sure the weight of the products are accurate.

- Anti-Corrosion – The surface layer of the wheel weights is first electrogalvanized, then apply multilayer and omni-dimension plastic spraying process.

- Eco-Friendly – The material of the products is lead-free, universal for 50 states.

- U.S White Tape – U.S made Four-Season Tape makes the perfect sticking results, wide paper backing designed for easy peeling.

- Specification – 1 segment: 1/2 oz 1 strip : 4 segments 1 box: 6 strips In total 1box=6strips=24segments=12oz

- Used on most domestic passenger cars, light trucks, SUVs, vans with alloy wheels

- Hardened spring steel clips for improved weight retention

- CKAuto MC series coated wheel weight features a special polymer coating that prevents the wheel from being stained by weights

- CKAuto lead weight series meet OEM quality specifications, designed to fit unique wheel flange profile

- Specification: Color: Grey, 25pcs/box, MC Style, 1.5 oz, Coated.

- ACCURATE - Ensuring accuracy in weights, made of high-quality materials and maintain close tolerances for precision

- EXPERIENCE SUPERIOR DRIVING - our assorted stick-on wheel weights featuring a reliable adhesive tape that ensures a secure and long-lasting attachment to the wheel

- ANTI-CORROSION - The exterior is fortified with a rustproof coating, providing protection against corrosion, while the interior is meticulously zinc-plated to ensure resistance to corrosive elements

- Our tire balancing weights are crafted from non-lead materials, compliant with regulations across all 50 states

- 1/2oz per segment,12 Segment per strips,52 strips per box,total 624pcs 156 OZ

Last update on 2025-05-08 / Affiliate links / Images from Amazon Product Advertising API

This product presentation was made with AAWP plugin.