| “This site contains affiliate links for which OEMDTC may be compensated” |

NHTSA ID Number: 10079701

Manufacturer Communication Number: GCUS-9-1466

Summary

14588C – SPECIAL COVERAGE (REVISED LABOR TIME). POLICE PATROL VEHICLES, IDLING THE ENGINE FOR EXTENDED PERIODS OF TIME CAN PREMATURELY WEAR THE ENGINE-COOLING-FAN MOTOR. IN THIS CONDITION, THE MOTOR MAY FAIL TO OPERATE OR OPERATE NOISILY. THIS CONDITION CAN ALSO DAMAGE MOTOR-CONTROL RELAYS IN THE VEHICLES UNDERHOOD BUSSED ELECTRICAL CENTER (UBEC). IF CONDITION OCCURS WITHIN STATED SPECIAL COVERAGE TERMS, DEALERS ARE TO DIAGNOSE AND REPLACE FAN MOTORS PER PI1384 REGARDING THE SEMI-ANNUAL PREVENTATIVE MAINTENANCE CHECK FOR POLICE VEHICLE COOLING FANS

10 Affected Products

Parts

| Description | Quantity/ Vehicle | Part Number |

| MOTOR KIT, ENG CLG FAN | 2 | 22762591 |

| MOTOR KIT, ENG CLG FAN (RIGHT) | 1 | 89018696 |

| MOTOR KIT, ENG CLG FAN (LEFT) | 1 | 89018695 |

| BLADE KIT, ENG CLG FAN (RIGHT) | 1 | 89018693 |

| BLADE KIT, ENG CLG FAN (LEFT) | 1 | 89018691 |

| MOTOR KIT, ENG CLG FAN | 2 | 92191945 |

| RELAY JUMPER HARNESS | 1 | 84008379 |

| DURASEAL SPLICE TUBE | 2 | 19300089 |

| DURASEAL SPLICE TUBE | 4 | 19300091 |

| NYOGEL LUBE | As Required | 12377900 |

| TIE STRAP | 4 | 12337820 |

| RIVET | 2 | 11561734 |

SEOCONTENT-END

SEOCONTENT-START

| Subject: | 14588B – Special Coverage Adjustment – Engine Cooling Fan Motor |

| Models: | 2011-2015 Chevrolet Caprice |

| 2012-2016 Chevrolet Impala | |

| Equipped as Police Patrol Vehicles (RPO 9C1 or 9C3) |

14588

2011-2015 model year Chevrolet Caprice and 2012-2016 model year Chevrolet Impala police patrol vehicles, idling the engine for extended periods of time can prematurely wear the engine-cooling-fan motor.

In this condition, the motor may fail to operate or operate noisily. This condition can also damage motor-control relays in the vehicle’s underhood bussed electrical center (UBEC).

This special coverage covers the condition described above for a period of 6 years or 100,000 miles (160,000 km), whichever occurs first, from the date the vehicle was originally placed in service, regardless of ownership.

Dealers are to diagnose and replace fan motors per PI1384 regarding the semi-annual preventative maintenance check for police vehicle cooling fans. The repairs will be made at no charge to the customer.

For vehicles covered by Vehicle Service Contracts, all eligible claims with repair orders on or after July 23, 2015, are covered by this special coverage and must be submitted using the labor operation codes provided with this bulletin. Claims with repair orders prior to July 23, 2015, must be submitted to the Service Contract provider.

Parts Information

| Part Number | Description | Quantity/ Vehicle |

| 22762591 |

MOTOR KIT, ENG CLG FAN | 2 |

| 89018696 |

MOTOR KIT, ENG CLG FAN (RIGHT) | 1 |

| 89018695 |

MOTOR KIT, ENG CLG FAN (LEFT) | 1 |

| 89018693 | BLADE KIT, ENG CLG FAN (RIGHT) | 1 |

| 89018691 | BLADE KIT, ENG CLG FAN (LEFT) | 1 |

| 92191945 |

MOTOR KIT, ENG CLG FAN | 2 |

| 84008379 | RELAY JUMPER HARNESS | 1 |

| 19300089 |

DURASEAL SPLICE TUBE | 2 |

| 19300091 |

DURASEAL SPLICE TUBE | 4 |

| 12377900 |

NYOGEL LUBE | As Required |

| 12337820 |

TIE STRAP | 4 |

| 11561734 | RIVET | 2 |

Service Procedure

Note: There are multiple Technical Service Bulletins related to the coolant fan motors in these vehicles. Please refer to Service Information for proper diagnostic procedures.

Caprice Only

- Using the diagnostic steps in Service Information and Technical Service Bulletins, determine if the engine coolant fan motors need to be replaced.

- If necessary, replace the coolant fan motors. Refer to Engine Coolant Fan Motor Replacement in Service Information.

Impala Only

Inspect the vehicle and service history to determine if the updated engine cooling fan wiring harness kit has been installed.

- If the revised engine coolant fan wiring harness has been installed, proceed to step #1 below.

- If the revised engine coolant fan wiring harness has NOT been installed, proceed to the Engine Cooling Fan Wiring Harness Installation section below.

- Using the diagnostic steps in Service Information, determine if the engine coolant fan motors need to be replaced.

- If necessary, replace the coolant fan motors. Refer to Engine Coolant Fan Motor Replacement in Service Information.

Engine Coolant Fan Motor Wiring Harness Installation

- Disconnect the battery.

- Remove the passenger side motor compartment front cross brace.

- Remove the passenger side head lamp and the G101 ground bolt.

- Disconnect the cooling fan wiring harness from the fans. Carefully disengage the retainer clips of the factory harness from the fan shroud. Use care to not damage the attachment features on the shroud, they will be reused.

- Cut the cooling fan wiring branch at the headlamp opening area. Measure approximately 100mm from the main wire bundle. This branch contains the White, Black, Grey and Light Blue wires. Remove and discard the cut off fan harness.

- Seal the four cut leads of the harness with four Duraseal Splice Tubes. Wrap the cut harness section with electrical tape to prevent moisture damage.

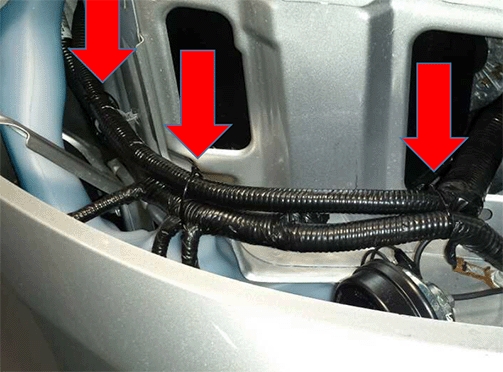

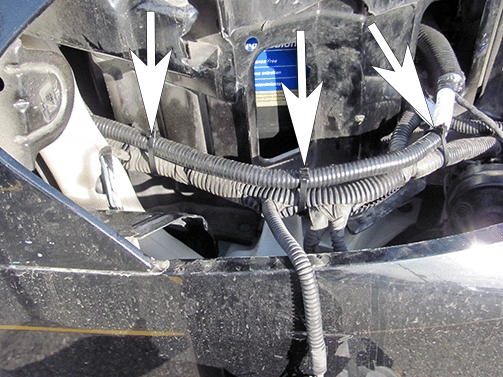

- Route the new harness along the bottom of the fan shroud and engage the retainer clips into the mounting holes in the fan shroud.

- Add Nyogel Lube to the terminals of both fan connectors on the new harness. Connect the fan connectors to the fan motors.

- Route the new fan harness into the passenger side headlamp pocket area.

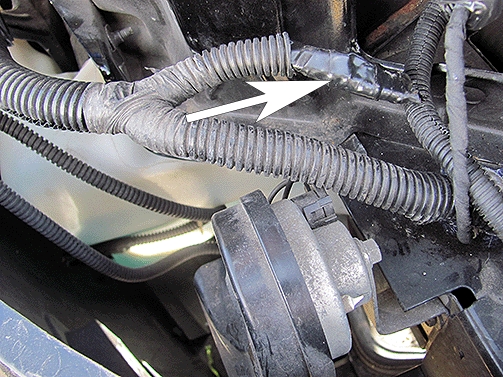

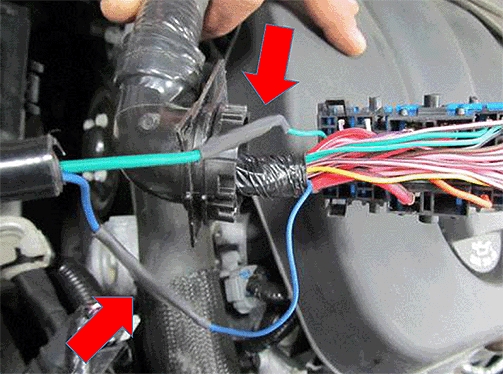

- Route the harness through the headlamp area, inboard of the windshield washer fluid bottle, then outboard of the UBEC. Loosely install three tie straps, do not tighten the straps at this time.

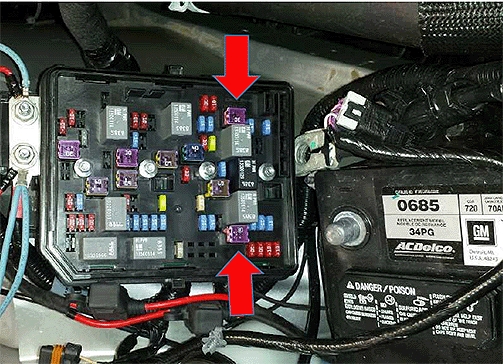

- Route the fan control wires (D-GN and D-BU) outboard of the UBEC to the engine harness, in the area where it enters the UBEC. Place the two harness fuses outboard of the UBEC.

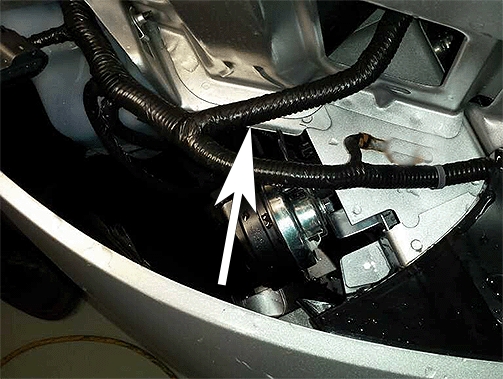

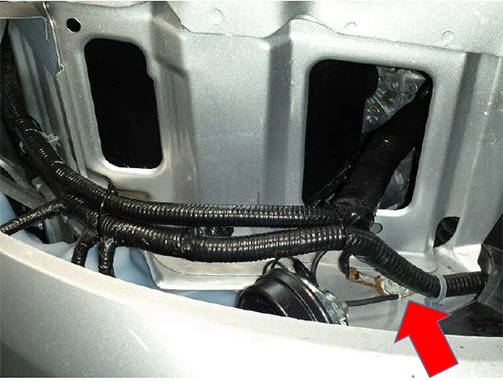

- Route the ground wire of the new harness through the passenger side head lamp opening and install over the G101 ring terminal (see below). Reinstall the ground bolt.

Tighten

Tighten the bolt to 10 +/- 2 Nm.

- Remove the UBEC cover.

- Remove the nuts from both UBEC battery studs, and remove all ring terminals. The convoluted conduit on the left ring terminal may not be present in some vehicles. It may appear as double-crimped fusible links to a single ring terminal.

- Unscrew the four UBEC connector bolts and remove the UBEC.

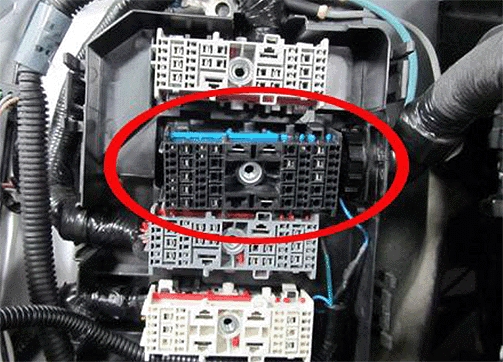

- Remove the engine harness connector and turn over to access the wiring.

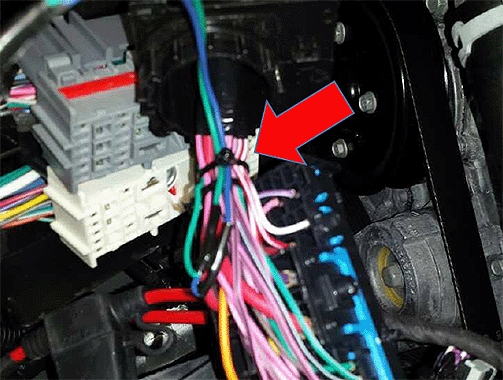

- Find the fan control wires in the engine harness: D-GN wire, 22 AWG, circuit 335 (Cavity H7), and D-BU wire, 22 AWG, circuit 473 (Cavity C7).

Note: There is 1 additional D-GN/WH stripe wire (22 AWG) and 1 DK-GN wire (20 AWG). The required D-GN wire is a 22 AWG wire.

- Extract the D-GN and D-BU control wires and cut the wires. Stagger wire cut points to permit splices to lay end-to-end. Apply electrical tape to the wire ends going into the UBEC connector.

- Splice the new fan relay control wires from new harness (D-GN and D-BU) to the matching cut wire ends leading to PCM. Apply heat to the heat shrink tubes to seal the splices.

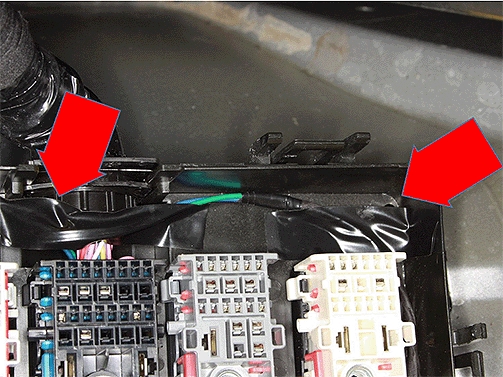

- Return the spliced wires into the UBEC splash shield between the connectors, routing them so they will not be crushed during the UBEC re-installation. Using a tie strap, secure the spliced wires near the existing tie strap on the engine harness connector.

- Use electrical tape to keep the two wire leads in place during UBEC re-installation.

- Route the two wires out of the UBEC.

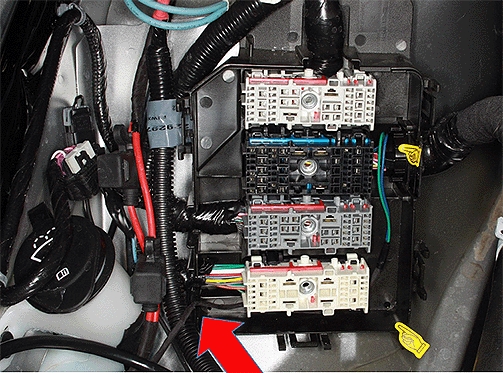

- Install the UBEC back in place and tighten the 4 connector bolts.

Tighten

Tighten the bolt to 6 +/- 2 Nm.

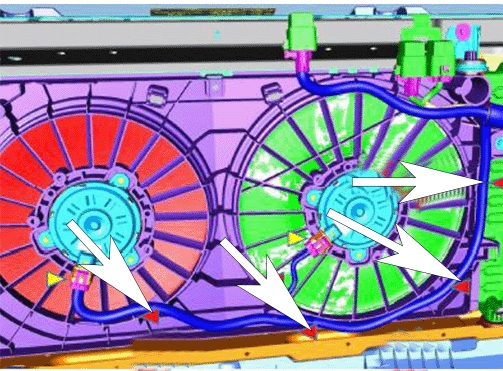

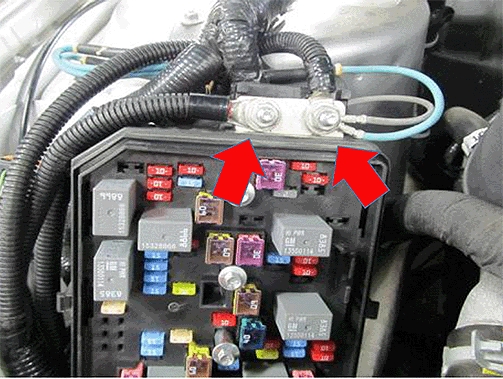

- Re-install all original ring terminals to the UBEC battery studs. Install the 2 ring terminals (RED) of the new harness to the studs as follows: route the shortest ring terminal lead to the RH UBEC stud and the longest lead to the LH battery stud. Orient the ring terminals with the crimp up and displaced angularly to permit all the ring terminals to lie flat. Reinstall the nuts.

Tighten

Tighten the nuts to 15 +/- 3 Nm.

- Remove, and discard, both Cooling Fan Fuses in UBEC. They are on each side of the Cooling Fan Relays.

- Reinstall the UBEC cover.

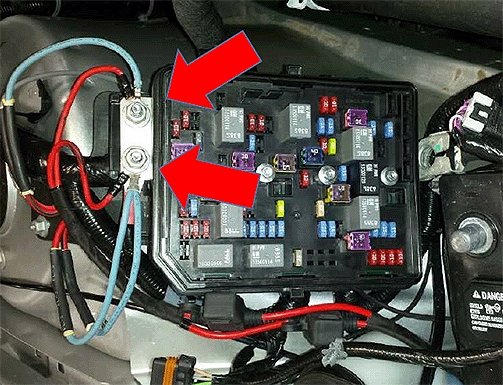

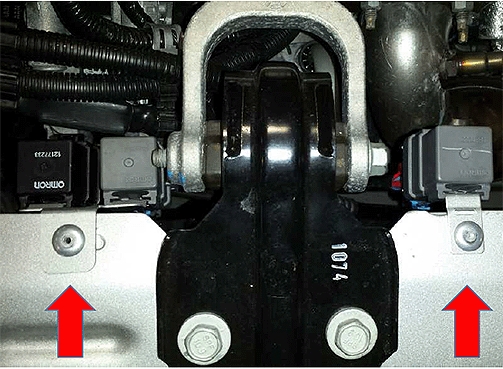

- Position the relay and bracket assemblies on the upper radiator support as shown, Mark the drill location with a paint pen. Note that the double relay bracket is located on the passenger side of the upper engine mount.

Note: Avoid drilling spot welds in the radiator support.

- Using a 5mm drill bit, drill the 2 relay bracket mounting holes in the upper radiator support. Treat all exposed metal with GM Super Lube®, or equivalent.

- Install the relay brackets to the radiator support using two (2) rivets.

- Re-install the passenger side cross brace.

Tighten

Tighten the nuts to 10 Nm.

- Check all routing, especially the position of the J-Case fuse holders and the leads to the UBEC near the cross brace.

- Tighten the 3 tie straps after checking all routing of the new harness.

- Install the passenger side head lamp.

- Reconnect the negative battery cable.

Tighten

Tighten the nut to 6 +/- 2 Nm.

- Perform a test of the fan harness by turning the engine ON, and activating the A/C. Both fans should start operating instantly.

SEOCONTENT-END

NHTSA ID Number: 10079701

Manufacturer Communication Number: GCUS-9-1466

Bulletin No.: 14588B

Date: November 2015

To View or Download this Document Click Here

Loading...

Loading...

Bulletin No.: 14588A

Date: October 2015

To View or Download this Document Click Here

Loading...

Loading...

Bulletin No.: 14588A

Date: October 2015

To View or Download this Document Click Here

Loading...

Loading...

Bulletin No.: 14588

Date: July 2015

To View or Download this Document Click Here

Loading...

Loading...

Bulletin No.: 14588

August 2015

To View or Download this Document Click Here

Loading...

Loading...

| “This site contains affiliate links for which OEMDTC may be compensated” |

- ✔️【PREMIUM QUALITY】Thick copper barrel ensures strong secure crimping every time, providing minimal voltage drop, high current flow, and less heat. These will prevent short circuits and problematic wiring that inferior connectors are known for

- ✔️【DURABILITY】Each terminal features a thick tinned copper barrel that resists corrosion to hold the wire tight when crimped. The barrel is created from one seamless piece of copper that eliminates the problem of the barrel opening. Your wire will never slip out of the connector

- ✔️【WATERPROOF】Insulation tubing has unique dual-walled design. High quality 3:1 shrinkage tubing has a heat-activated sealant lining to provide a 360 degree secure seal. It's flame-retardant, waterproof, and can be used underground

- ✔️【WIDE APPLICATIONS】Compliant with all electrical standards, Perfect for marine and automobile applications, whether you are working on your boat, Vehicle, Home or scientific project, our electrical crimp connector will ensure strong watertight seal to make sure everything bond correctly. The connector assortment includes red (AWG 22 – 16), blue (AWG 16 – 14) and yellow (AWG 12 – 10) butt connectors that can be used on wire AWG from 22 to 10

- ✔️【TICONN BRAND QUALITY COMMITMENT】We stand behind the quality of our products. If for any reason you are not satisfied with your purchase, please contact us. We provide 30-day money back and 24-month warranty. 100% Satisfaction Guarantee for risk-free shopping!

- 16-22 AWG +16-14 AWG +12-10 AWG

- Color: Red Yellow Blue

- Standard crimp and then seal heat shrink butt connectors; Guaranteed to hold the strong crimps

- Dual-walled design, polyolefin tubing in outside and hot melt adhesive in inside

- Package Content: Red*20pcs+Blue*20pcs+Yellow*10pcs

- 16-22 AWG +16-14 AWG +12-10 AWG

- Color: Red Yellow Blue

- Standard crimp and then seal heat shrink butt connectors; Guaranteed to hold the strong crimps

- Dual-walled design, polyolefin tubing in outside and hot melt adhesive in inside

- Package Content: Red*40pcs+Blue*50pcs+Yellow*10pcs

- PREMIUM COPPER CORE AND HEAT SHRINK TUBE: Made of high quality tinned copper and adhesive lined heat shrink tubing. These professoinal butt connectors ensure protection against the elements. Heat shrink tubing provides high tensile strength and resistance to stretch and mechanical damage, high thickness copper core ensure protection against the elements

- STRONG CRIMPS: These butt connectors use thick, seamless copper barrels. Your wire will not pull out of these butt splices when crimping

- EXCELLENT WIRE CONTACT: The copper barrel provides increased current flow, and ensures less voltage drop, preventing wiring failures and reducing equipment downtime

- RELIABLE CONNECTION: Adhesive lined inside the 3:1 butt heat shrink connector will exude hot melt adhesive when evenly heated, shrinks quickly and adheres to wire insulation. Guarantees good environmental sealing, waterproof and wear-resistant

- WIDE APPLICATIONS: Excellent stability, water resistance and electrical conductivity provide durable connection for motorcycle, off-road vehicles, lawn tractors,RVs,fish finder and marine application. Widely used on multiple projects of your Christmas lights,ships with high waterproof requirements motorcycle stereo, boat electronics, equipment switches

- The UPC of the product is 805089657073

- This product is a lawn and garden tool accessories

- This product is manufactured in China

- Sold in pack of 10

- Yellow color

- Shrinkable sleeve

- The UPC of the product is 805089657011

- This product is a lawn and garden tool accessories

- This product is manufactured in China

- Includes 50pcs of Butt Connectors

- Heat Shrinkable Butt Splice Connectors (DHSCS) is made of polyolefin, with adhesive lining for protecting splices from water, condensation, salt.

- Our cores are copper.

- Heat Shrinkable Butt Splice Connectors (DHSCS) is made of polyolefin, with adhesive lining for protecting splices from water, condensation, salt.

- Unlike other connectors with Brass or Tinn inner cores, our cores are copper.

- Includes 100pcs of Crimp Terminal Wire Tips

Last update on 2025-05-08 / Affiliate links / Images from Amazon Product Advertising API

This product presentation was made with AAWP plugin.