| “This site contains affiliate links for which OEMDTC may be compensated” |

NHTSA ID Number: 10115005

Manufacturer Communication Number: PIT5429

Summary

This Preliminary Information communication provides information to the technician the steps to diagnose and repair vehicles that have rough, harsh, or stiff ride. The concern is most noticeable between 35-55 mph on fairly smooth roads, when coming in contact with small road imperfections, or expansion joints. Technician will need to use the vibration analyzer CH-51450-A (Pico Oscilloscope), while driving the vehicle in 35-55 mph range on the same section of road for each stage of evaluation. If a rough, harsh, stiff ride has been determined to be the customer?s concern following evaluation using the Pico scope, then replace the complete front suspension shock with coil spring assemblies, and rear shocks with updated parts and reprogram the Suspension Control Module (K19) with updated calibrations available in TIS2WEB.

6 Affected Products

Vehicles

CADILLAC | ESCALADE | 2015 |

CADILLAC | ESCALADE ESV | 2015 |

| CHEVROLET | SUBURBAN | 2015 |

| CHEVROLET | TAHOE | 2015 |

| GMC | YUKON | 2015 |

| GMC | YUKON XL | 2015 |

Parts

| Front | ||||

| Spring Asm-Frt Coil (w/ Shock) | C157 06 | 6YR, 7YR, 6HD, 7HD | 1 side | 23312152 |

| Spring Asm-Frt Coil (w/ Shock) | C157 06 | 6ZC, 7ZC, 6HF, 7HF | 1 side | 23312153 |

| Spring Asm-Frt Coil (w/ Shock) | C159 06, K157 06 | 6ZD, 7ZD, 6H3, 7H3 | 1 side | 23312154 |

| Spring Asm-Frt Coil (w/ Shock) | C159 06, K157 06 | 6ZN, 7ZN, 6H4, 7H4 | 1 side | 23312155 |

| Spring Asm-Frt Coil (w/ Shock) | C159 06, K157 06 | 6ZP, 7ZP, 6JU, 7JU | 1 side | 23312156 |

| Spring Asm-Frt Coil (w/ Shock) | K159 06 | 6ZR, 7ZR, 6XF, 7XF | 1 side | 23312157 |

| Spring Asm-Frt Coil (w/ Shock) | K159 06 | 6ZS, 7ZS, 6XH, 7XH | 1 side | 23312158 |

| Rear | ||||

| Absorber Asm-Rr Lvlg Shock | ALL | ALL | 1 Side | 23267007 |

SEOCONTENT-START

Bulletin No.: PIT5429

Date: Jun-2015

| Subject: | Rough Harsh Ride |

| Models: | 2015 Cadillac Escalade Escalade |

| 2015 Chevrolet Tahoe LTZ, Suburban LTZ | |

| 2015 GMC Yukon Denali | |

| With Magnetic Ride Control Suspension (RPO Z95) | |

| Vehicles Built Before 2/10/2015 | |

| Attention: | Installing the updated suspension components and calibration call out in this will NOT provide a ‘sofa-on-wheels’ type of ride, and will NOT eliminate tire/wheel, propshaft, rear axle related inputs/disturbances; they are designed specifically to address the rough, harsh rough/harsh/stiff ride concern. |

The following diagnosis might be helpful if the vehicle exhibits the symptom(s) described in this PI.

Condition/Concern

The new 2015 Full-Size Utilities incorporate suspension design improvements for improved handling, decreased stopping distances, reduce body roll, etc. Many customers are very satisfied with the ride and handling, but some owners may feel the ride is not to their satisfaction. They may comment of a rough/harsh/stiff ride, or they may describe a vehicle vibration with a similar description.

Typically, this condition is most noticeable between 35-55 mph on fairly smooth roads, when coming in contact with small/minor road imperfections/bumps, expansion joints, etc. The suspension will absorb larger bumps without complaints, but smaller/minor imperfections/bumps, which would normally be absorbed by the suspension, may not be absorbed as well as the owner would expect.

Recommendation/Instructions

Evaluate the vehicle using the vibration analyzer CH-51450-A (Pico Oscilloscope), driving the vehicle in 35-55 mph range on the same section of road for each stage of evaluation. Pico scope will normally show this ride condition as a Tire 2 or Unknown vibration (approximately 15-19 Hz) in response to small/minor road imperfections/bumps. The vibration analyzer should be used twice: 1st to determine the customer concern is a rough/harsh/stiff ride and 2nd after the repairs to verify the cause is repaired and to identify if other inputs / disturbances are present. The Hz and Mg readings should be documented using the Z95 rough/harsh/stiff ride / vibration chart below.

Important: When using the vibration analyzer make sure to obtain readings after the vehicle has been driven at least 10-15 miles to warm up the tires and cycle the new shocks. After new shocks are installed they will need to be cycled before optimum ride is obtained, which is done during normal driving.

[During evaluation, position the Pico accelerometer sensor to capture Both vertical and horizontal planes, for tri-axis sensor, ensure correct orientation for X, Y, and Z axis. Place the sensor on the seat track, console (avoid wireless charging mat), steering column, etc. If additional sensors are used, place at each vehicle corner to help narrow area of strongest input/disturbance.]

| Z95 MR Rough/Harsh/Stiff Ride / Vibration Worksheet | |

|---|---|

| Road Condition | Small/minor road imperfections/bumps, expansion joints, etc. |

| Speed Condition Occurs | 35-55 MPH (55-90 KPH) |

| Pico Scope Readings Before Any Repairs | |

| Sensor Mounted Vertical or Y plane at Drivers Seat Rail: | Sensor Mounted Horizontal or Z plane at Drivers Seat Rail: |

| MPH/KPH:__________ Hz:__________ m/g’s:__________ | MPH/KPH:__________ Hz:__________ m/g’s:__________ |

| Sensor Mounted Vertical or Y plane at _____________: | Sensor Mounted Horizontal or Z plane at ___________: |

| MPH/KPH:__________ Hz:__________ m/g’s:__________ | MPH/KPH:__________ Hz:__________ m/g’s:__________ |

| Pico Scope Readings After Repairs | |

| NOTE: Ensure vehicle is driven 10-15 miles to warm the tires and cycle the new shocks | |

| Sensor Mounted Vertical or Y plane at Drivers Seat Rail: | Sensor Mounted Horizontal or Z plane at Drivers Seat Rail: |

| MPH/KPH:__________ Hz:__________ m/g’s:__________ | MPH/KPH:__________ Hz:__________ m/g’s:__________ |

| Sensor Mounted Vertical or Y plane at _____________: | Sensor Mounted Horizontal or Z plane at ___________: |

| MPH/KPH:__________ Hz:__________ m/g’s:__________ | MPH/KPH:__________ Hz:__________ m/g’s:__________ |

If a rough/harsh/stiff ride has been determined to be the customer’s concern, following evaluation using the Pico scope, then replace the complete front suspension shock with coil spring assemblies, and rear shocks with updated parts and reprogram the Suspension Control Module (K19) with updated calibrations available in TIS2WEB. (The calibration may be labeled “Real Time Damping.”) The updated part numbers listed below utilize various improvements to address the ride concern as described.

Note: Vehicle alignment does not need to be adjusted as a result of the Z95 MR suspension component updates.

Please note that this rough/harsh/stiff ride / vibration condition can be magnified by other inputs/disturbances which may be present, such as: Tire and wheel assemblies with excessive road force variation (RFV), propshaft balance / runout, and/or rear axle pitchline runout related issues. These updated suspension components will Not correct these other inputs/disturbances, which Must be addressed separately. If an issue in any of these other areas is found, it should be corrected Before returning the vehicle to the customer, See the latest version of PI1354 “Vibration Analysis And Diagnostic” to work through other inputs/disturbances.

Following Z95 MR-related updates, re-evaluate the vehicle to ensure no other inputs/disturbances are present. If other inputs/disturbances are present, review the additional diagnostic tips in this PI and correct the remaining conditions:

Additional Diagnostic Tips -Tire and Wheel AssembliesEnsure tire and wheel assemblies are not contributing to the issue. Keep in mind this rough ride issue will often show up as T2 in response to road input, (suspension reacting to road input, rather than absorbing it). If T1 is present, or any higher order, other than some T2 in direct-response to road input, expansion joints, etc. the tire and wheel assemblies must be investigated. There have been some cases of T2 tire issues, some high-speed RFV issues (primarily with the 22-inch Bridgestone tires), and some cases of tire/wheel assemblies showing acceptable RFV numbers, but with further investigation, have been found to have bent inboard rim flanges with hidden tire damage, visible inside when dismounted.

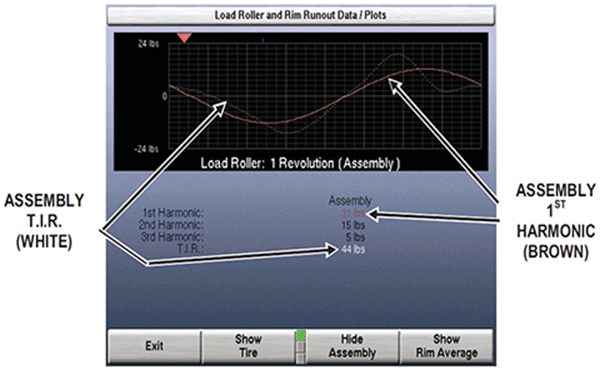

The GSP9700 checks tire low-speed RFV only, in the radial plane only

The GSP9700 is set to display T1 RFV. Higher order RFV, T2 & T3 can be displayed in the Assembly Data Plots Screen, as shown above. Depending on the level of GSP9700, the screen may be under ‘Data’ or ‘Runout Plots,’ then “Rim and Load Roller Runout Plots.”

When checking tires on the GSP9700, if (radial) T2 is high or close to the (radial) T1 value, the tire should be replaced. As an example, if a tire and wheel assembly is measuring T1 at 10 lbs RFV, the tire would be considered good; however, if in displaying the higher orders, it is found that the tire and wheel assembly also has T2 at say 9 lbs RFV, the tire needs to be replaced. Refer to the latest version of PI1354 for latest procedures.

| Road Force Variation (RFV) Specification to Address Ride Concerns | |

|---|---|

| P-Metric Tires on Light Trucks, SUVs | 15 lbs (6.8 kg) or Less |

| NOTE: Arrange the tires on the vehicle in the following order: lowest RFV at LF, next RF, next LR, highest RR | |

-Propeller ShaftEnsure the propshaft is not contributing to the issue. If any orders of P measured with significance on the Pico in vertical or horizontal planes – inspect the propshaft for dents or other damage. If no damage is present, check propshaft balance and runout, refer to the latest version of PI1354 “Vibration Analysis And Diagnostic” for latest procedures. Remember to consider and inspect the transmission output shaft bushing for irregular wear.

-Rear Drive AxleEnsure the rear drive axle is not contributing to the issue. Pitchline runout / gear set machining, followed by setup issues have been found to be contributors to vibration issues; not just whine noise concerns.Gear set machining issues in these axles seem to most often show up as P1 or higher order P related; with some showing as T1 or higher order of T related; all depending on gear set condition.

If tire/wheel assemblies and propshaft have been ruled out / repaired, and P1, T1 or a higher order of P or T is still present in the vertical or horizontal plane – other than in direct-response to road input, the drive axle must be investigated

Check for pitchline runout and setup issues, refer to the latest version of PI1354 “Vibration Analysis And Diagnostic” for latest procedures.

If drive axle repair is necessary, we have heard some reports that during repair, tooling chatter marks may be observed in the pinion race counterbores. This issue lends to the idea that the races may not be fully seated until some vehicle use is introduced into the axle. This issue would most often result in a noise concern, though severe loss of preload might produce a vibration. The races should be able to be fully seated during repair

Parts Information

| Part Number | Description | Vehicle Model | Spring Code | Qty |

| Front | ||||

| Note: Verify spring code RPOs, LH and RH for vehicle from the SPID label or IVH/GWM. Some vehicles by-design will have LH / RH spring codes which fall into different groupings / different part numbers for each side – they must be serviced in the same manner to best address this ride concern. For example: A truck with LH spring code of 6ZS, with RH spring code of 7ZR would use 23312158 for the Left side and 23312157 for the Right side. | ||||

| 23312152 | Spring Asm-Frt Coil (w/ Shock) | C157 06 | 6YR, 7YR, 6HD, 7HD | 1 side |

| 23312153 | Spring Asm-Frt Coil (w/ Shock) | C157 06 | 6ZC, 7ZC, 6HF, 7HF | 1 side |

| 23312154 | Spring Asm-Frt Coil (w/ Shock) | C159 06, K157 06 |

6ZD, 7ZD, 6H3, 7H3 | 1 side |

| 23312155 | Spring Asm-Frt Coil (w/ Shock) | C159 06, K157 06 |

6ZN, 7ZN, 6H4, 7H4 | 1 side |

| 23312156 | Spring Asm-Frt Coil (w/ Shock) | C159 06, K157 06 |

6ZP, 7ZP, 6JU, 7JU | 1 side |

| 23312157 | Spring Asm-Frt Coil (w/ Shock) | K159 06 | 6ZR, 7ZR, 6XF, 7XF | 1 side |

| 23312158 | Spring Asm-Frt Coil (w/ Shock) | K159 06 | 6ZS, 7ZS, 6XH, 7XH | 1 side |

| Rear | ||||

| 23267007 |

Absorber Asm-Rr Lvlg Shock | ALL | ALL | 1 Side |

Warranty Information

For vehicles repaired under warranty use:

| Labor Operation | Description | Labor Time |

| 8080158* | Replace Both Front Coil Spring/Shocks, Replace Both Rear Shocks and Reprogram Suspension Control Module Programming | 3.5 hr** |

| * This is an unique labor operation for bulletin use only. This will not be published in the Labor Time Guide. | ||

| ** This includes Before and After PICO Scope Diagnosis | ||

Please follow this diagnostic or repair process thoroughly and complete each step. If the condition exhibited is resolved without completing every step, the remaining steps do not need to be performed.

SEOCONTENT-END

Bulletin No.: PIT5429

Date: Jun-2015

To View or Download this Document Click Here

Loading...

Loading...

| “This site contains affiliate links for which OEMDTC may be compensated” |

- Use your PicoScope 2000 Series as an advanced oscilloscope, spectrum analyzer, function generator, arbitrary waveform generator and decode over 30 serial protocols as standard out of the box.

- PicoScope 2204A 2 Channel Oscilloscope kit includes: USB 2.0 cable (USB 3.0/3.1 compatible), two x1/x10 passive probes and Quick Start Guide.

- 10 MHz bandwidth, 100 MS/s maximum sampling rate, 8 kS capture memory and Up to 12 bits enhanced vertical resolution.

- Ultra-compact design, USB connected and powered. Travel-friendly and ideal for small-scale setups, it fits in a laptop bag.

- PS7 Software for Windows, Linux and Mac. PicoScope 7 has all the analysis tools you need to get answers quickly, whether carrying out a simple test, or debugging a complex design. New features are continuously being added through free software upgrades, meaning your PicoScope will keep improving!

- Use your PicoScope 2000 Series as an advanced oscilloscope, spectrum analyzer, function generator, arbitrary waveform generator and decode over 30 serial protocols as standard out of the box.

- PicoScope 2204A-D2 2 Channel Oscilloscope kit includes: USB 2.0 cable (USB 3.0/3.1 compatible) and Quick Start Guide.

- 10 MHz bandwidth, 100 MS/s maximum sampling rate, 8 kS capture memory and Up to 12 bits enhanced vertical resolution.

- Ultra-compact design, USB connected and powered. Travel-friendly and ideal for small-scale setups, it fits in a laptop bag.

- PS7 Software for Windows, Linux and Mac. PicoScope 7 has all the analysis tools you need to get answers quickly, whether carrying out a simple test, or debugging a complex design. New features are continuously being added through free software upgrades, meaning your PicoScope will keep improving!

- Oscilloscope probes NOT included

- Oscilloscope probes NOT included

- Scope 2205A 2 channel 25 MHz, 8-bit oscilloscope with probes

- 25 MHz bandwidth

- 1 GS/s sampling

- Advanced digital triggers

- Arbitrary waveform generator

- Use your PicoScope 2000 Series as an advanced oscilloscope, spectrum analyzer, function generator, arbitrary waveform generator and decode over 30 serial protocols as standard out of the box.

- PicoScope 2205A 2 Channel Oscilloscope kit includes: USB 2.0 cable (USB 3.0/3.1 compatible), two x1/x10 passive probes and Quick Start Guide.

- 25 MHz bandwidth, 200 MS/s maximum sampling rate, 16 kS capture memory and Up to 12 bits enhanced vertical resolution.

- Ultra-compact design, USB connected and powered. Travel-friendly and ideal for small-scale setups, it fits in a laptop bag.

- PS7 Software for Windows, Linux and Mac. PicoScope 7 has all the analysis tools you need to get answers quickly, whether carrying out a simple test, or debugging a complex design. New features are continuously being added through free software upgrades, meaning your PicoScope will keep improving!

- 22PCS Back Probe Kit is for harness connectors, automotive sensors and fuel injectors.

- Back Probe is made of Stainless Steel ,15pcs with 3 kind (Straight, 90 degree, 135 degree) and five color.

- 5PCS banana plug(standard 4mm) with copper alligator clips wires, 5 colors to identify.

- 2 PCS Nickel plated copper Alligator clips.

- Back Probe can test up to 30 volts. easier use on automotive connectors.

- 4 analog channels

- 25MHz bandwidth

- Built-in AWG in every model

- 500 MS/s

- 48 kS buffer

- HT30A: 3M BNC to banana adapter cable, heavy duty auto test lead. Allowing the oscilloscope away form the car being tested or repaired and placed on the bench

- HT30A: It consists of wide range probes, clips, gators can be plugged into the 4 mm connectors at the end of the cable.Full shield can effectively reduce the noise interference

- HT30A: A special line for assisting automobile measurement instruments to test various types of signals. which also can cooperate with a 20:1 attenuator

- HT201: HT201 Attenuator designed for assisting automobile measurement. Passive attenuator with 20:1 attenuation, if input a 20V signal, it can output a 1V signal. Bandwidth: 10MHz

- This oscilloscope accessories set suitable for auto measurement, it work better when used together, it meet your various demand of your oscilloscope test

- Scope 2205A-D2 2 channel 25 MHz, 8-bit oscilloscope (no probes)

- 25 MHz bandwidth

- Advanced digital triggers

- Arbitrary waveform generator

- Serial decoding

- 8-Channel Automotive Oscilloscope: A virtual oscilloscope that combines various functions, general-purpose oscilloscope functions and a programmable signal generator

- Universal Oscilloscope Function: 8 analogue channels, 12 bits resolution, 4K memory depth, 2.4MSa/s real-time sampling rate; 20 automatic measurement modes, can be selected with one key to turn on or off, convenient and intuitive to read the signal measurement results

- Programmable Signal Generator with USB storage: 8 channels, LVTTL output level, 0-250KHz frequency range. Signal generator function to simulate crankshaft and camshaft signals

- The 8-channel oscilloscope is easy to operate and suitable for electricians as well as technicians, hobbyists and electronics enthusiasts to learn basic circuit diagnostics, basic electronic equipment troubleshooting, home appliances and other electronic products. Can transfer signals through the USB 2.0 interface, easy to connect to Android devices such as tablets, smart phones and personal computers

Last update on 2025-05-08 / Affiliate links / Images from Amazon Product Advertising API

This product presentation was made with AAWP plugin.