| “This site contains affiliate links for which OEMDTC may be compensated” |

NHTSA ID Number: 10113629

Manufacturer Communication Number: PI1474

Summary

This preliminary informational bulletin provides repair information to correct a customer concern of Air Bag indicator Illuminated with technician finding DTC B0012 or B0013 set.

2 Affected Products

Vehicles

Parts

| Service Connector | 13580115 |

SEOCONTENT-START

#PI1474: Air Bag Indicator Illuminated with DTC B0012 or B0013 – (May 5, 2015)

| Subject: | Air Bag Indicator Illuminated with DTC B0012 or B0013 |

| Models: | 2015 Cadillac ATS, CTS Sedan (VIN A) ATS, CTS Sedan (VIN A) |

| Built Between August 1 through October 1, 2014 | |

| Attention: | This PI also applies to any of the above models that may be Export vehicles. |

Condition/Concern

Some customers may comment that the AIR BAG indicator is illuminated.

Technicians may find code B0012 or B0013 with symptom bytes 04 or 0D set as current or in

history.

This condition may be caused by poor terminal tension in X85 Steering Wheel Air Bag Coil X3 connector.

Recommendation/Instructions

Important: Before replacement of the steering wheel air bag coil or steering wheel air bag, testing for proper terminal tension at the steering wheel air bag coil X3 connector should be performed.

If the condition above exists, test for proper terminal tension at the steering wheel air bag coil X3 connector.

Follow the instructions below:

Warning: This vehicle is equipped with a Supplemental Inflatable Restraint (SIR) System. Failure to follow the correct procedure could cause the following conditions:

X3 Connector Terminal Tension Testing

- Disable the SIR system. Refer to the SIR Disabling and Enabling in SI.

- Remove the steering column upper trim cover. Refer to the Steering Column Upper Trim Cover Replacement in SI.

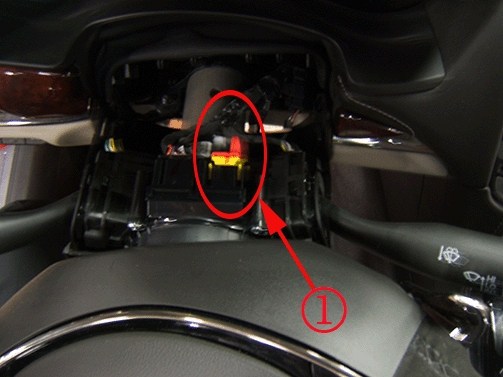

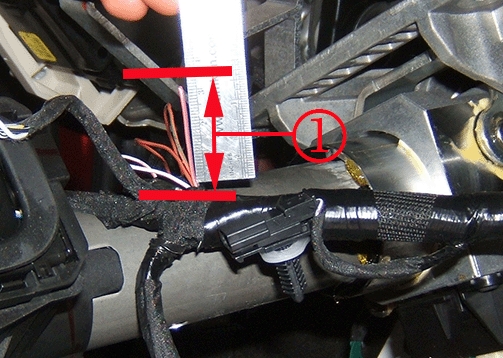

- Disconnect the X85 Steering Wheel Air Bag Coil X3 connector (1), illustrated above.

- Test probe each terminal for poor tension with J-35616–65B (LT BU).

- If the terminal tension is within specification, continue diagnoses. Refer to the diagnostic trouble code (DTC) B0012 or B0013 in SI.

- If one or more terminal tension is found to be poor, replace the connector with service connector P/N 13580115 with the next steps of this procedure.

- Remove the steering column lower trim panel. Refer to the Steering Column Lower Trim Cover Replacement in SI.

- Remove the instrument panel knee bolster deflector. Refer to the Driver Knee Bolster Reinforcement Replacement in SI.

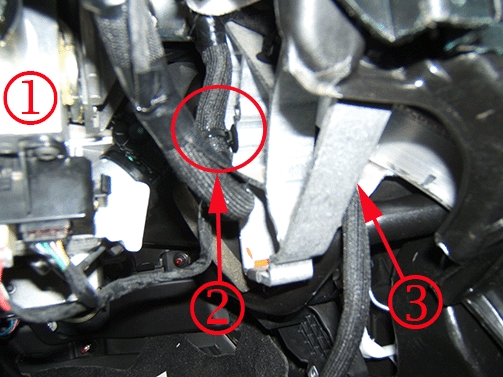

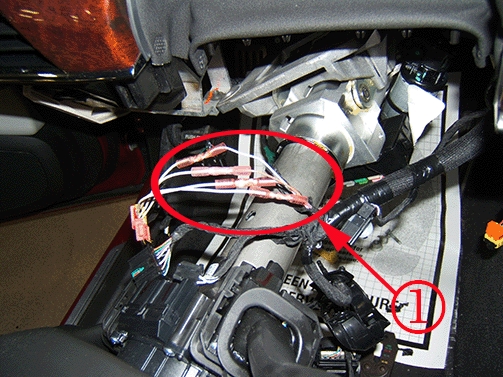

- Release the steering column wiring retainer (2) between the steering column (1) and the instrument panel tie bar (3) as illustrated above.

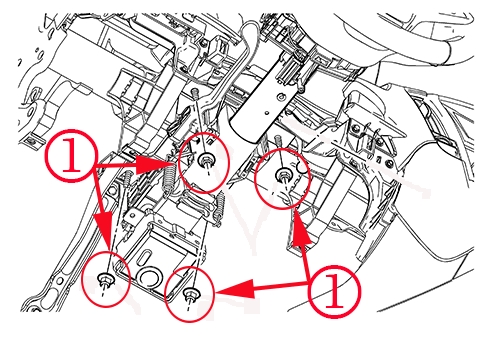

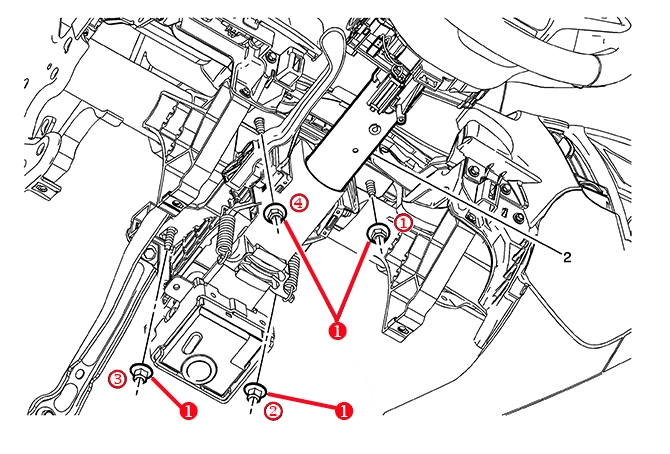

- Remove the four nuts (1) from the steering column that secure the column in place.

Note: This procedure is only lowering the steering column to allow access to steering column wiring harness to replace X3 connector for the SIR coil. Removal of the upper intermediate steering shaft bolt is NOT necessary.

Caution: After the removal of the steering column nuts, the column will not be secured in place. Take caution in lowering the steering column.

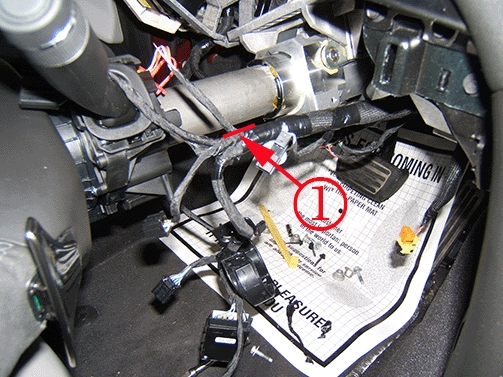

- Disengage the steering column wiring harness bracket (1) and any electrical connectors (2) to allow the wiring harness to be free from the column for repair.

- Remove the anti-abrasion tape until the main harness (1) as illustrated.

- Cut the first I/P wire to be repaired approximately 32 mm (1.25 in) as illustrated.

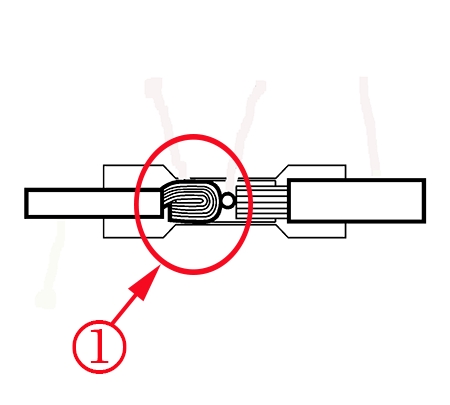

- Strip approximately 10 mm (0.40 in) of insulation from the I/P wire to perform folded-over wire repair (1).

- Twist and then fold over the wires.

Note: Twisting the wires before folding prevents the wire strands from opening up.

- Strip approximately 5.0 mm (0.20 in) of insulation to the circuit being repaired from the service connector.

Note: The length of the service connector wiring is too long. Cutting the wires shorter is necessary before installing the splice sleeve.

- Install the salmon (yellow-pink) DuraSeal splice sleeve to the wires using the J-38125–8, crimp nest 1.

- Stagger the next three splice sleeves (1) toward the X3 connector as illustrated above.

- Ensure to perform the fold-over wire repair to the I/P wires before installing the splice sleeve.

- Using a J-38125–5A Ultra Torch or equivalent, apply heat to each sleeve at the crimped area of the barrel.

Note: DO NOT use soldering equipment that is battery or electric powered. These types of soldering irons can induce voltage into the circuit, which may cause inflator module deployment and/or damage to electrical components. Use only the J-38125–5A Ultra Torch or another butane fueled soldering iron when working on SIR circuits.

- The tubing will shrink completely as the heat is moved along the insulation.

- A small amount of sealant will come out of the end of the tubing when sufficient shrinkage is achieved.

- Rewrap the wires with anti-abrasion tape or equivalent.

- Reinstall the steering column wiring harness bracket and all electrical connectors.

- Ensure the X3 connector harness will not interfere with the steering column upper trim cover or any other components.

- Reinstall the steering column.

Tighten

Tighten the nuts (1) in sequence as illustrated to 22 Nm (16 lb ft).

- Reinstall the steering column wiring retainer between the steering column and the instrument panel tie bar.

- Reinstall the instrument panel knee bolster deflector. Refer to the Driver Knee Bolster Reinforcement Replacement in SI.

- Reinstall the steering column upper and lower trim cover. Refer to the Steering Column Upper Trim Cover Replacement and Steering Column Lower Trim cover in SI.

- Enable the SIR system. Refer to the SIR Disabling and Enabling. Refer to the SIR Disabling and Enabling in SI.

- Verify the AIR BAG indicator turns OFF.

Parts Information

| Part Number | Description |

| 13580115 | Service Connector |

Warranty Information

For vehicles repaired under the Bumper-to-Bumper coverage (Canada Base Warranty coverage), use the following labor operation. Reference the Applicable Warranties section of Investigate Vehicle History (IVH) for coverage information.

| Labor Operation | Description | Labor Time |

| 6480178* | Steering Wheel Airbag Coil Connector Replacement | 0.6 hr |

| *This is a unique Labor Operation for Bulletin use only. It will not be published in the Labor Time Guide. | ||

SEOCONTENT-END

Bulletin No.: PI1474

Date: May-2015

To View or Download this Document Click Here

Bulletin No.: PI1474

Date: May, 2015

To View or Download this Document Click Here

- Time Saver: Solderless,crimpless, all you need is just a heat gun to finish the joint, much faster and easier than the old way

- Fit for Confined and Narrow Spaces: Can be bent after connection and no need to crimp or solder in the confined area, just control the temperature via a heat gun

- Waterproof and Seal Performance: There is two hot melt waterproof adhesive rings in each butt connector, which help it hold up better to moisture

- High Temperature Proof in A Short Time: Use exclusive material in the butt connectors to avoid shrink tubing melting before solder ring

- IATF16949:2016 Listed: The Kuject solder seal connectors meet the newest standard of International Automotive Task Force, which is the most standardized way for you to repair or modify your car

- 【PREMIUM IN QUALITY】- Every single piece of our crimp connectors is made with tinned thick red copper barrel and polyolefin heat shrink tubing[Shrink Ratio 3:1], which ensure secure crimping and tight wire connection with high current flow and minimum voltage drop, preventing wire failures

- 【SAFETY MATTERS】- Safety is the top priority during any of your work, certificated products can ensure you reassured and secure using experience. Our heat shrink connectors meet the standards of CE, RoHS, ISO9001, SGS, you’re allowed to use these proffesional butt splice connectors with full confidence for a variety of electrical projects and wire connection issues

- 【MADE TO LAST】- Thanks to the thick tinned copper and seamless barrel desgin, it ensures strong and secure crimping all the time with no wire coming off issues. What's more, the polyolefin heat shrink tubing provides the high tensile strength and resistance to mechanical damage so there's no worry of rat chewing or similiar phisical damage issues. When heated with a heat gun, the adhesive melting inside create a waterproof and insulated seal, preventing electric leakage and corrosion

- 【WIDE APPLICATION】- Marine grade heat shrink butt splices can be widely applied in areas such as automotive industry, marine, science projects, family electrical wire connections and so on, due to its durability, steadily, water and corrosion resistace

- 【COST EFFECTIVE PACKAGE】- Considerate product quantity of 100pcs/pack

- COMPLIANT WITH ALL RELEVANT STANDARDS:With Haisstronica 330PCS( A.W.G.:22-16 150 PCS,16-14 100 PCS,12-10 32 PCS,26-24 48 PCS) heat shrink waterproof wire connectors are compliant with ROHS, ISO 9001:2008, SGS, and CE standards

- HIGH-QUALITY COPPER CORE:Heat shrink butt connectors use a copper core with a higher thickness rating.This makes your connection project safer and better meets our customers’ quality needs

- HIGH-QUALITY HEAT SHRINK:Translucent heat shrink tubing provides high tensile strength and resistance to stretch and minimize mechanical damage.The thick barrel ensures a strong crimp every time.The inner wall of the heat-shrinkable tube has enough hot melt adhesive to ensure waterproof performance reliability.Your wire will never slip out of these heat shrink wire connectors

- RECOGNIZABLE:Tubings of varying colors with easily recognizable wire gauge markings. Simply measure the wiring, and by checking the mark of wire gauge of the polyolefin tubing, then you can quickly choose the right connector

- WIDE APPLICATIONS: High quality 3:1 shrinkage tubing has a heat-activated sealant lining to provide complete secure seal. It's flame-retardant, waterproof, and can be used underground. Compliant with all electrical standards, Perfect for marine and automobile applications, whether you are working on your boat, Vehicle, Home or scientific project

- ✔️【PREMIUM QUALITY】Thick copper barrel ensures strong secure crimping every time, providing minimal voltage drop, high current flow, and less heat. These will prevent short circuits and problematic wiring that inferior connectors are known for

- ✔️【DURABILITY】Each terminal features a thick tinned copper barrel that resists corrosion to hold the wire tight when crimped. The barrel is created from one seamless piece of copper that eliminates the problem of the barrel opening. Your wire will never slip out of the connector

- ✔️【WATERPROOF】Insulation tubing has unique dual-walled design. High quality 3:1 shrinkage tubing has a heat-activated sealant lining to provide a 360 degree secure seal. It's flame-retardant, waterproof, and can be used underground

- ✔️【WIDE APPLICATIONS】Compliant with all electrical standards, Perfect for marine and automobile applications, whether you are working on your boat, Vehicle, Home or scientific project, our electrical crimp connector will ensure strong watertight seal to make sure everything bond correctly. The connector assortment includes red (AWG 22 – 16), blue (AWG 16 – 14) and yellow (AWG 12 – 10) butt connectors that can be used on wire AWG from 22 to 10

- ✔️【TICONN BRAND QUALITY COMMITMENT】We stand behind the quality of our products. If for any reason you are not satisfied with your purchase, please contact us. We provide 30-day money back and 24-month warranty. 100% Satisfaction Guarantee for risk-free shopping!

- Multiple Choices: Proper ratio of various types to meet the commonly used types needs. This wiring terminals kit contains ring, fork, spade, and heat shrink butt connectors

- Stronghold and Durability: We adopt premium copper core to ensure good electrical conductivity and durability. Heat shrink crimp connectors provides greater pull strength

- Waterproof: With the adhesive melted when heated, the heat shrink tubing seals all the way to the end of the barrel. The connections were to be outside or inside the vehicles, will perform good water proof

- Straightforward Visual Inspection: Translucent, adhesive-lined polyolefin tubing for straightforward visual inspection, prevents wire corrosion, and provides a waterproof seal

- Wide Applications: Good electrical conductivity and water proof provide connection for your automotive, motorcycle, and marine application. Widely used on multiple projects of your vehicle or ATV lighting, motorcycle stereo, boat electronics, equipment switches

- [EXECELLENT QUALITY] : Direct factory with excellent quality control, STRONG & DURABLE. The copper core of our heat shrinkable joints is made of high quality tinned copper, in addition to being extremely conductive, it is easier to flatten and grip the wire

- [EASY USE] : Take two wires you wish to join. Remove the wire insulator, pick the terminal color you want. Insert the wire into the terminal one at the time and crimp by crimping tool, insert another terminal and crimp. Use air gun to apply heat on the heat shrink connectors.

- [PRACTICAL DESIGN] : Double-wall design, outer layer of polyolefin tube, inner layer of hot melt adhesive, precise crimping and good contact. Electrical butt connectors provide high tensile strength and adequate hot melt adhesive inside the tube. After shrinking, the wiring is firm and not loose, and it can ensure that the current continues to flow smoothly.

- [WIDE APPLICATIONS] : Our waterproof terminals are perfect for marine, automobile applications, electrical and electronics industries. Whether working on your Boat, Vehicle, Home, or Scientific project, the electrical crimp connector will ensure a strong waterproof seal to make sure everything bonds correctly.

- [PACKAGE INCLUDED] : 25 pcs red connector ( 22-16 AWG ), 15 pcs blue connector ( 16-14 AWG ), 10 pcs yellow connector ( 12-10 AWG ).

- 3:1 Heatshrink Ratio: The heat shrink butt connector has dual-wall shrinking tube and inside hot melt glue, providing a fully safe seal and wire corrosion. Its dual wall insulation seals against moisture corrosion, air leakage, and can be used underground

- Premium Copper Core: The butt splice terminals use seamless and high-quality thick copper tubular, which makes the connection project safer! Fix the wire firmly, increase current flow, and decrease voltage drop

- Wide Usage: Our heat shrink wire connector is ideal for marine, automobile, industry, electrical and electronics. Whether working on boat, vehicle, RC car, home, scientific project, car stereo, or electrical DIY, the crimp connectors will work well

- Package Included: 50 pcs red waterproof wiring connectors for 22, 20, 18, 16 gauge wires, 40 pcs blue waterproof wiring connectors for 16, 14 gauge wires, 10 pcs yellow waterproof wiring connectors for 12, 10 gauge wires—total 100 pcs

- AIRIC Brand Advantages: As a professional manufacturer of electrical accessories, we own a large leading wire connectors factory and get UL, CE, ROHS, SGS, and ISO9001-2005 international quality system certification

- Tinned Copper Core: Butt connectors use a heavy-duty copper core, strong crimp, higher conductivity

- Package Includes: 100Pcs Blue heat shrink butt connectors that can be used on wire AWG from 16 to 14

- Solderless Crimping: Insert the wires to be connected, crimp both sides with crimping pliers, and then heat with a heat gun

- 3:1 Shrink Ratio: Marine grade heat shrink tubing provides high tensile strength and enough hot melt adhesive inside the tubing to ensure waterproof performance, your wires will never slip out of the wire connectors

- Wide Application: Wire connectors are waterproof, stable, and corrosion resistant and are used in the automotive, marine, electrical, and electronic industries

- [EXECELLENT QUALITY] - Direct factory with excellent quality control, STRONG & DURABLE. The copper core of our heat shrinkable joints is made of high quality tinned copper, in addition to being extremely conductive, it is easier to flatten and grip the wire

- [WATERPROOF] - Waterproof insulated, the polyolefin tubing on the outside and the hot-melt glue inner layer provide excellent water resistance when heated. The polyolefin tube reduces in size and the adhesive flows within the insulation

- [PERFECT FOR] - Perfect use for the repair technician on the electrical wiring. Seamless copper barrel design provides high tensile strength and mechanical damage resistance, translucent heat shrink tubing eliminates the issue of the barrel opening, high elasticity keeps steady performance

- [EASY USE] - Take two wires you wish to join. Remove the wire insulator, pick the terminal color you want. Insert the wire into the terminal one at the time and crimp by crimping tool, insert another terminal and crimp. Use air gun to apply heat on the heat shrink connectors

- [PACKAGE INCLUDES] - 200pcs Heat Shrink Butt Connectors. 3 Sizes, 90pcs Red, 9Opcs Blue and 20pcs Yellow.

- PREMIUM COPPER CORE AND HEAT SHRINK TUBE: Made of high quality tinned copper and adhesive lined heat shrink tubing. These professoinal butt connectors ensure protection against the elements. Heat shrink tubing provides high tensile strength and resistance to stretch and mechanical damage, high thickness copper core ensure protection against the elements

- STRONG CRIMPS: These butt connectors use thick, seamless copper barrels. Your wire will not pull out of these butt splices when crimping

- EXCELLENT WIRE CONTACT: The copper barrel provides increased current flow, and ensures less voltage drop, preventing wiring failures and reducing equipment downtime

- RELIABLE CONNECTION: Adhesive lined inside the 3:1 butt heat shrink connector will exude hot melt adhesive when evenly heated, shrinks quickly and adheres to wire insulation. Guarantees good environmental sealing, waterproof and wear-resistant

- WIDE APPLICATIONS: Excellent stability, water resistance and electrical conductivity provide durable connection for motorcycle, off-road vehicles, lawn tractors,RVs,fish finder and marine application. Widely used on multiple projects of your Christmas lights,ships with high waterproof requirements motorcycle stereo, boat electronics, equipment switches

Last update on 2025-05-08 / Affiliate links / Images from Amazon Product Advertising API

This product presentation was made with AAWP plugin.